Magnetron

A magnetron and magnetic pole technology, applied in the field of magnetron, can solve the problems of low microwave output efficiency, complex structure, and increased manufacturing cost, and achieve the effects of high microwave output efficiency, convenient process realization, and simple structural design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The specific embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

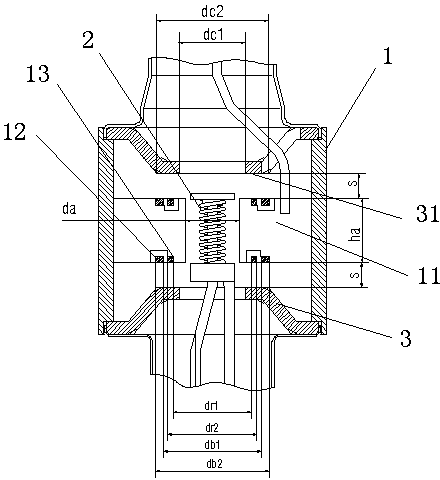

[0013] Such as figure 1 Shown, the present invention is a kind of magnetron, comprises anode part, cathode part, and anode part comprises the anode cylinder 1 of cylinder shape, is fixed on the anode cylinder 1 inner wall surface and is radial some anode blades 11 and places anode The large intersecting ring 12, the small intersecting ring 13 and the antenna coaxial with the anode cylinder 1 in the cylinder 1, the cathode part includes a central pole assembly coaxially assembled with the anode part and a helical filament 2 wound on the central pole assembly , a pair of tapered magnetic poles 3 of soft magnetic material are symmetrically installed on the axial direction of the anode part. The oscillation wavelength of the main oscillation π mode of the present invention is λ, and the oscillation frequency is fo. It is characterized in that th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com