Corrugated pipe-based optical fiber stress sensing device

An optical fiber stress and sensing device technology, applied in the field of devices, can solve problems such as hindering the improvement of the dynamic range and accuracy of the optical fiber sensor, limiting the dynamic range and accuracy of the optical fiber sensor, and the size of the plate cannot be too large, so as to achieve flexible use methods. , Increase the detection accuracy and sensitivity, increase the effect of the effective bending length

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

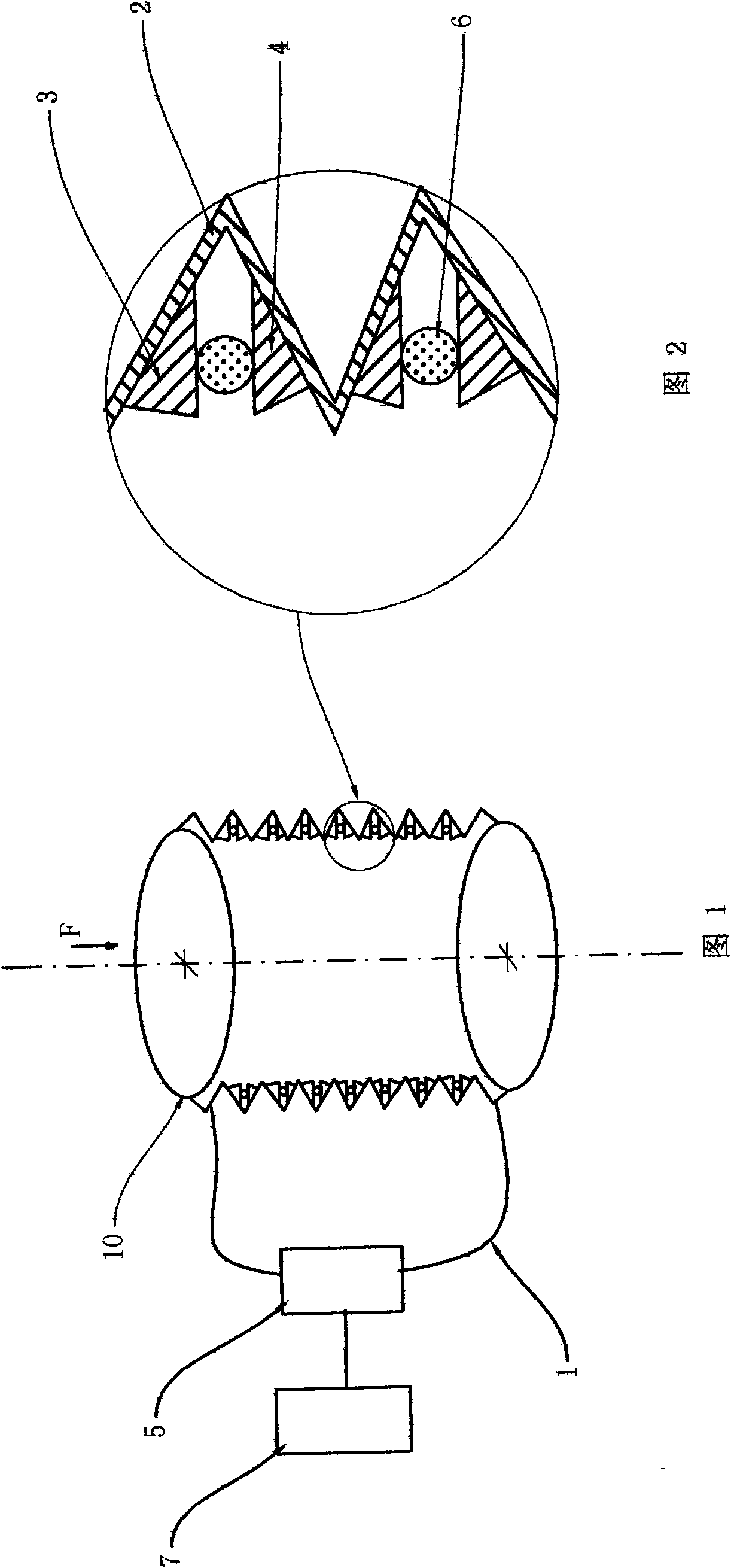

[0038] like figure 1 , figure 2 As shown, the present invention includes a side A deforming tooth 3 and a side B deforming tooth 4 respectively arranged on two opposite surfaces of the concave part of the inner wall of the pipe wall 2 of the bellows 10, and the deforming tooth 3 on the A side and the deforming tooth on the B side are respectively arranged. The teeth 4 are staggered and correspond to each other. The deformed teeth 3 on the A side and the deformed teeth 3 on the B side are correspondingly arranged on both sides of the signal fiber 6. The signal fiber 6 is connected to the test unit 5 through the extension fiber 1, and the test unit 5 is followed by a processing unit 7.

[0039] When the bellows 10 is stretched and deformed under stress, the distance between the deformed teeth 3 on the A side and the deformed teeth 4 on the B side on the wall 2 of the bellows 10 will also change, so that the deformed teeth are clamped between the two deformed teeth. The bending...

Embodiment 2

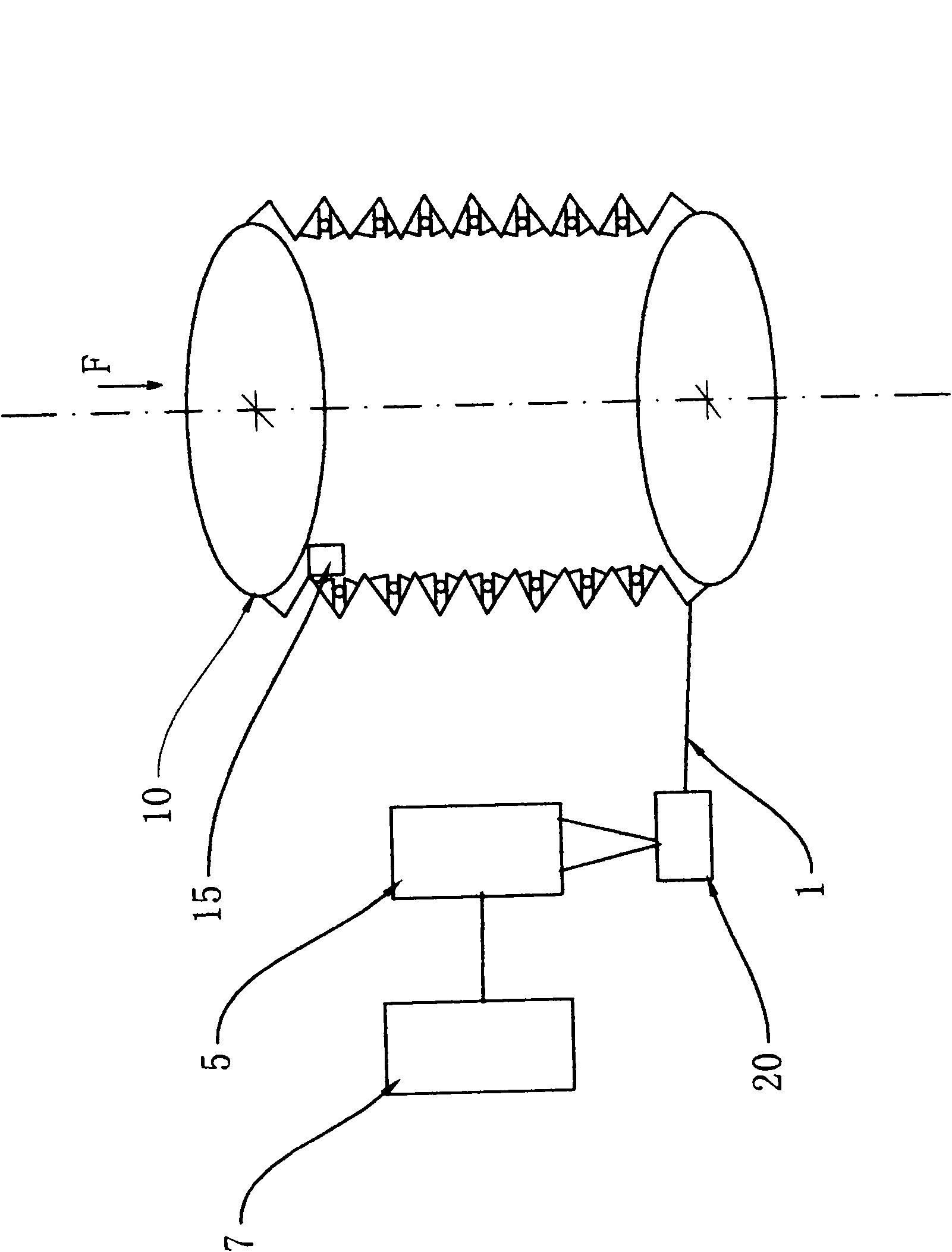

[0045] like image 3 As shown, in this embodiment, the difference from Embodiment 1 is that a light reflector 15 is arranged at one end of the signal fiber 6, the other end of the signal fiber 6 is connected to the extension fiber 1, and the extension fiber 1 is connected to a 1X2 optical branch. The 2 ends of the 1X2 optical splitter 20 are connected to the test unit 5, the test unit 5 can be composed of a stable light source and an optical power meter, and the test unit 5 is connected with the processing unit 7, so that the optical signal transmitted in the signal fiber 6 can be Passing through the bent portion of the signal fiber 6 twice further improves the precision and sensitivity of the detection device. In this embodiment, the structures, connection relationships and working principles of other parts are the same as those in Embodiment 1.

Embodiment 3

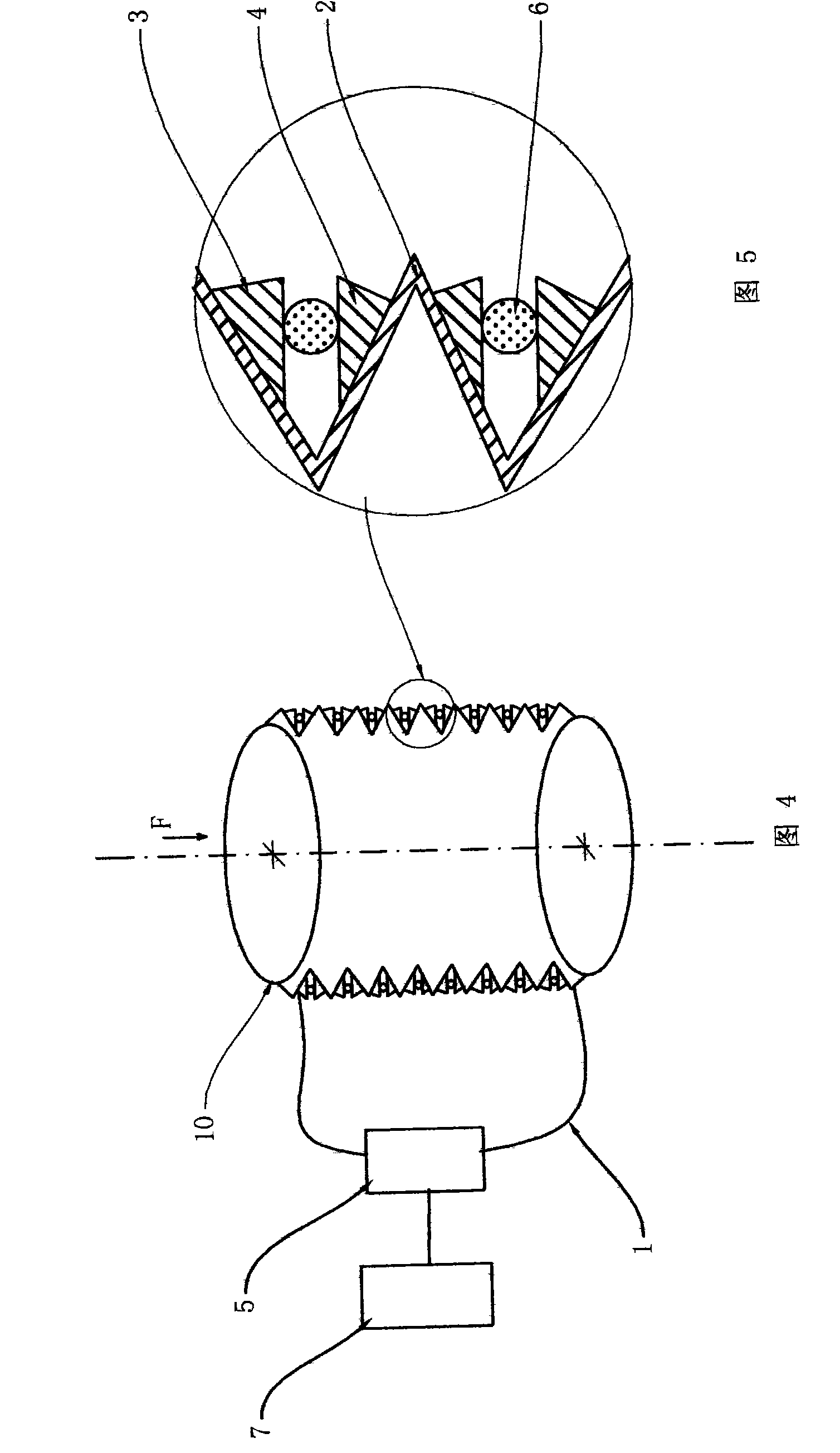

[0047] like Figure 4 , Figure 5 As shown, in this embodiment, the difference from Embodiment 1 is that the A-side deforming teeth 3 and the B-side deforming teeth 4 are arranged in the concave part of the outer wall of the pipe wall 2 of the corrugated pipe 10 . In this embodiment, the structures, connection relationships and working principles of other parts are the same as those in Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com