Special equipment for measuring positions of bottom claw threaded hole and crankshaft hole of cylinder block

A special equipment and threaded hole technology, applied in the field of detection devices, can solve the problems of cumbersome measurement tasks, large detection errors, and difficult to master, and achieve the effects of fast measurement speed, easy mastery, and simple measurement methods.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described in detail below in conjunction with the accompanying drawings and through specific embodiments. The following embodiments are only descriptive, not restrictive, and cannot limit the protection scope of the present invention.

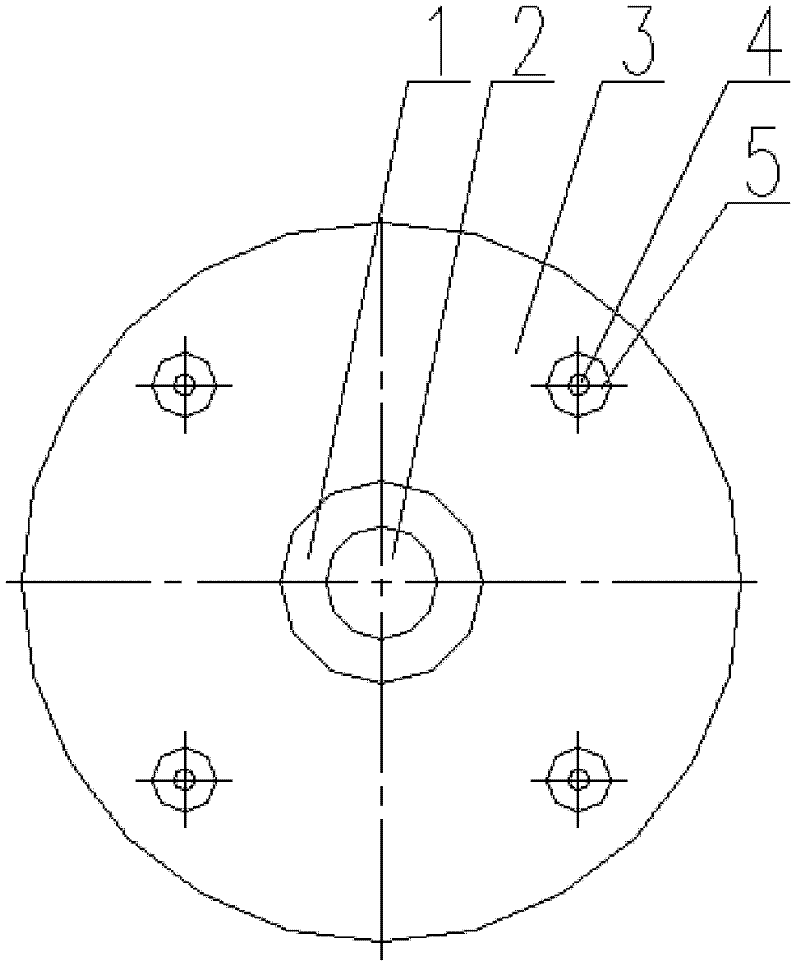

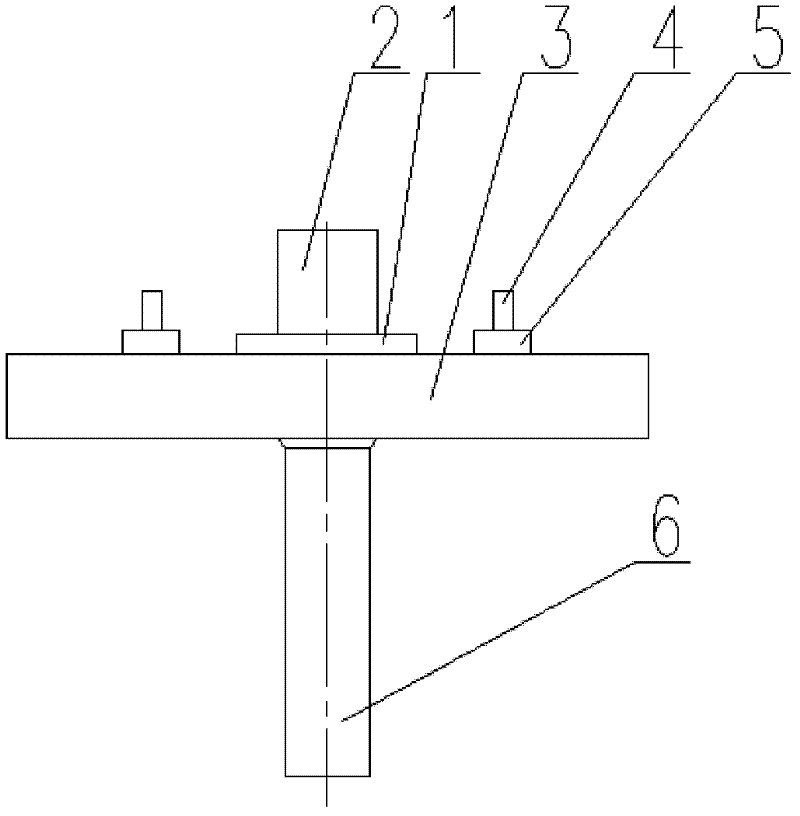

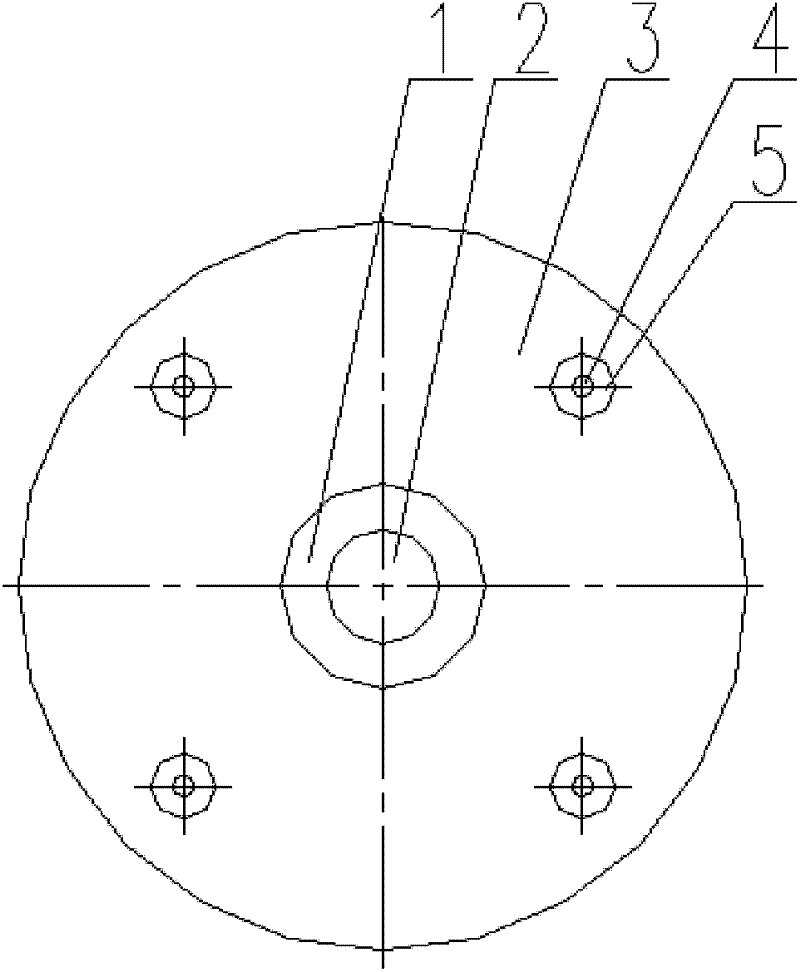

[0014] A special device for measuring the position of the threaded hole of the cylinder bottom claw and the crankshaft hole, including a detection round table 3, a bottom claw threaded hole detection column 4, a crankshaft hole detection column 2, and a handle 6, wherein the axial center of the detection circle table is upward A crankshaft hole detection column is made, and a crankshaft hole detection circular platform 1 with a slightly larger radius than the crankshaft hole detection column is radially formed on the detection round platform coaxial with the crankshaft hole detection column. The crankshaft hole detection column and the crankshaft hole detection round platform are used for detection Fo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com