Gas-material separation type flue gas diversion distribution device

A distribution device and separation type technology, applied in the direction of valve device, dry gas arrangement, valve operation/release device, etc., can solve fluidized bed channel flow, turbulent flow, fluidized bed dead bed, raw coal moisture content Large and other problems, to achieve the effect of eliminating potential safety hazards, efficient drying and humidity control, and improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

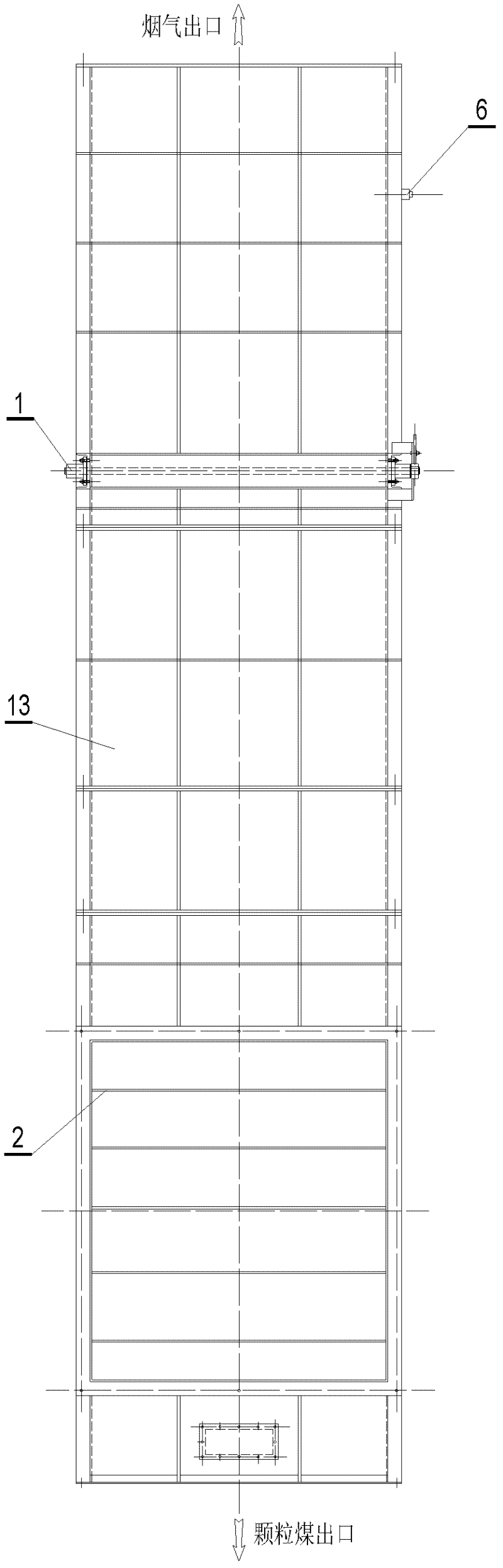

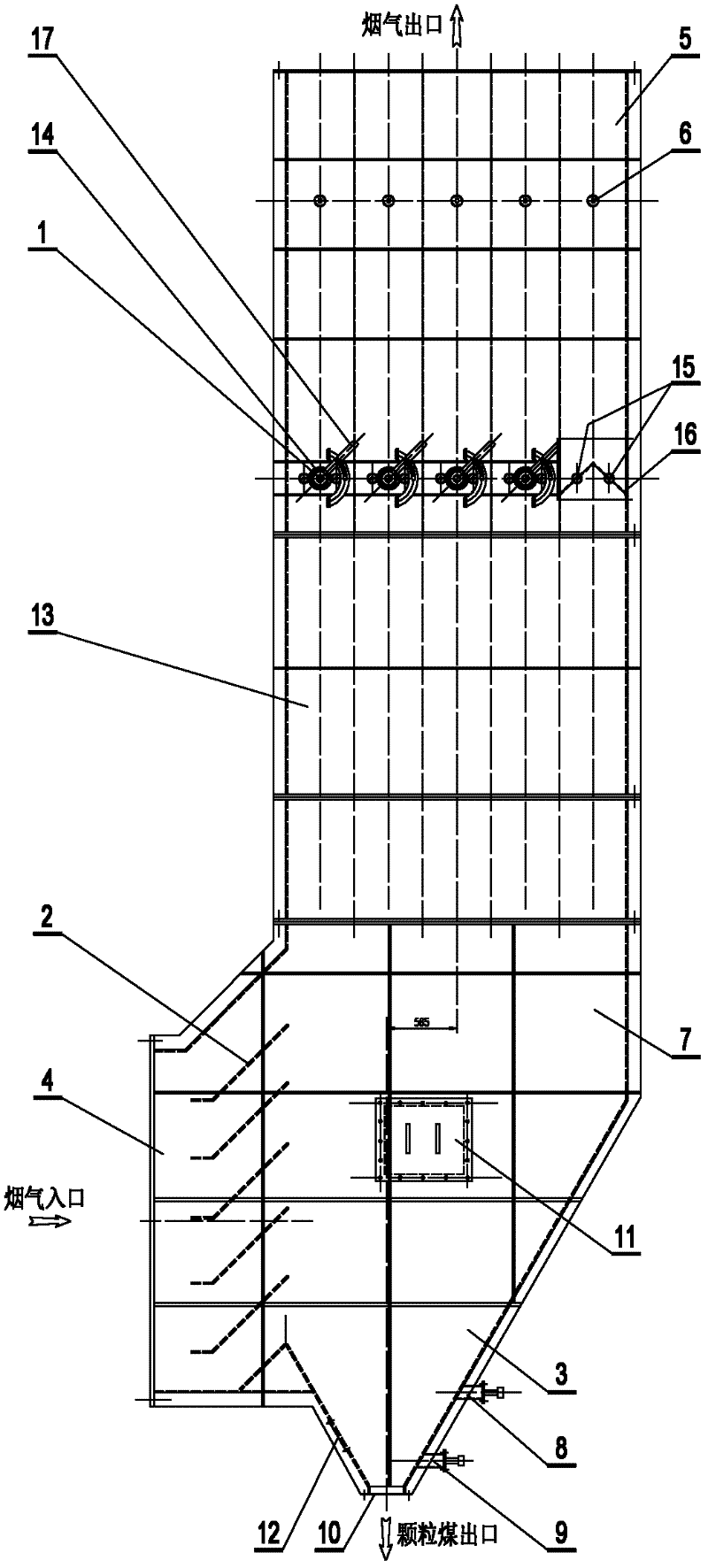

[0023] Below in conjunction with accompanying drawing, the present invention will be further described:

[0024] See figure 1 , figure 2 , gas material separation type flue gas diversion distribution device, this device is mainly used in the coal humidity control process system, used to realize the uniform distribution of the air flow for drying the wet coal material on the fluidized bed, and can also fall back in the fluidized bed The particulate coal to the flue gas delivery section is effectively separated from the air flow to avoid damage to the system fan. The device can also be used in other processes that have higher requirements on air distribution.

[0025] When operating in the coal humidity control process system, the flue gas inlet pipe 4 is connected to the fan outlet pipe, the flue gas outlet pipe 5 is connected to the fluidized bed flue gas inlet pipe, and the granular coal outlet pipe 10 is connected to the airtight discharge device .

[0026] Gas material...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com