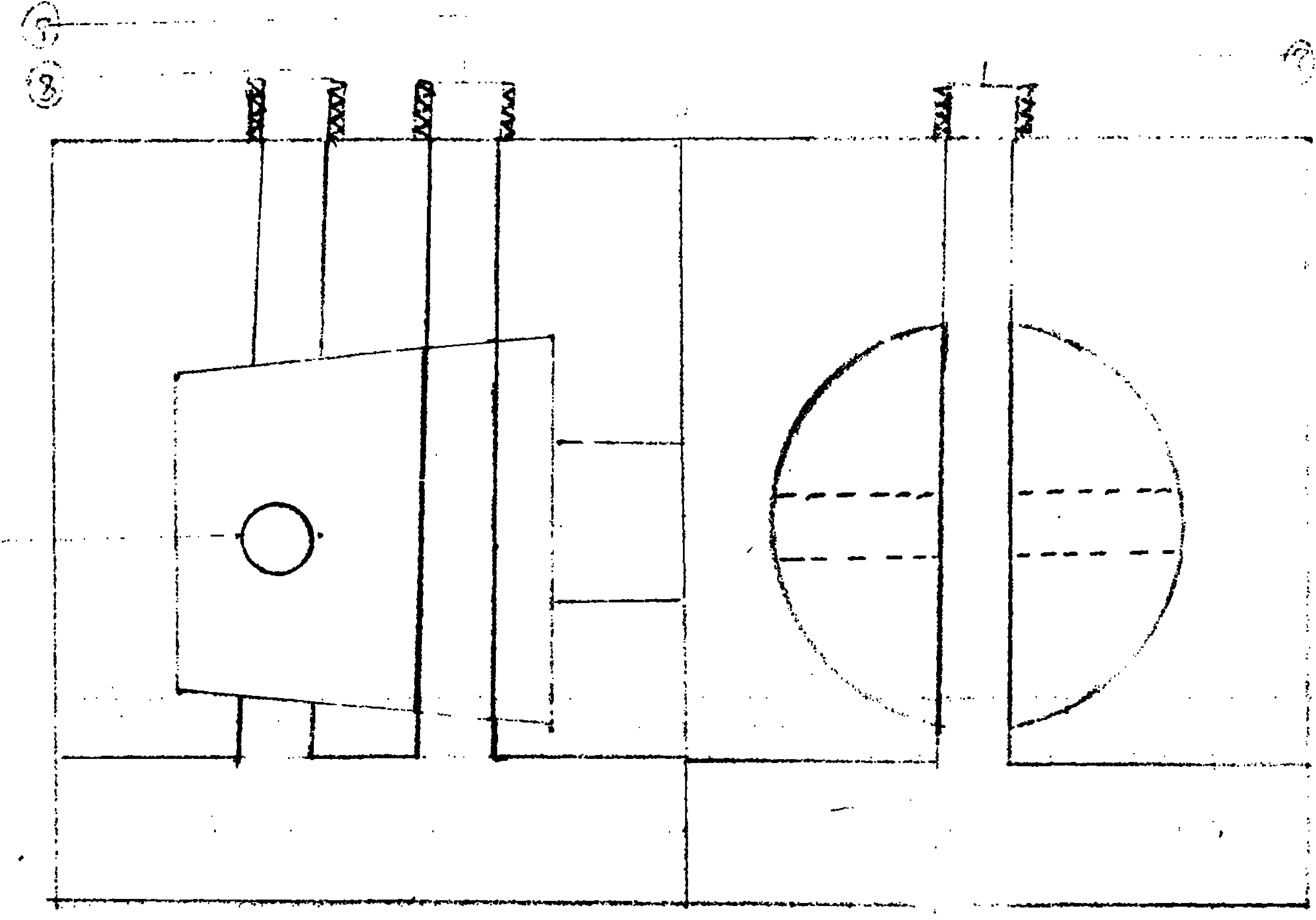

Oil economizer with cylinder-by-cylinder oil cutoff and grouped oil cutoff

A technology of cutting oil and grouping, applied in the direction of machine/engine, engine control, mechanical equipment, etc., can solve the problem of wasting oil and so on

Inactive Publication Date: 2012-02-01

杨金田

View PDF5 Cites 6 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0003] The problem solved by the present invention is because the current automobile engine is all designed by the maximum horsepower of the automobile, what the automobile used was the cylinder number of the maximum horsepower when running with a load, and also used the cylinder number of the maximum horsepower when running empty. When an empty car runs at high speed, the accelerator must also be added, so that a lot of oil will be wasted when the car is running empty. The problem is that it can distribute oil to the cylinders of the car according to the actual horsepower used by the car. When the car is empty, it can cut off part of the cylinder's oil and return it to the fuel tank according to the actual horsepower used by the car to achieve the purpose of saving fuel. When driving with a heavy load, you can connect the oil of all the cylinders to make the whole engine work and reach the maximum horsepower, so that the whole process of the car when the car is loaded and empty is the best fuel with the best horsepower. It saves a lot of fuel than an engine without a fuel saver

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

[0040] Specific implementation

[0041] Put it on the high-pressure oil pump, it will not damage the engine.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

The invention relates to an oil economizer, which is designed according to the traditional high-power engine. When an empty vehicle travels at high speed, oil in a part of cylinders can be cut off to return an oil tank. The oil economizer works with the number of cylinders with power suitable for the empty vehicle, thereby achieving the purpose of oil saving.

Description

Technical field [0001] The technical invention relates to a high-horsepower vehicle that can save fuel when running empty. Background technique [0002] The current car engines are designed for maximum horsepower. When the car is empty, especially at high speed, not only the cylinders of the entire engine work, but the accelerator must also be added, so that a lot of waste is wasted when the car is empty. Oil, this fuel economizer can cut off a part of the cylinder oil and return to the fuel tank when the vehicle is empty, and use the horsepower and number of cylinders suitable for the empty vehicle to achieve the purpose of fuel saving. Summary of the invention [0003] The problem solved by the present invention is because the current automobile engines are designed according to the maximum horsepower used by the automobile. The number of cylinders with the maximum horsepower is used when the automobile is running under a load, and the number of cylinders with the maximum horsep...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): F02D17/00

Inventor 杨金田

Owner 杨金田

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Patsnap Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com