Offshore wind power generation tower foundation and structure and installation and construction method thereof

A construction method and wind power generation equipment technology, applied in the field of foundation engineering, can solve problems such as heavy tower structure weight, high material cost, and difficult construction, and achieve the effects of saving material costs, reducing shift costs, and reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

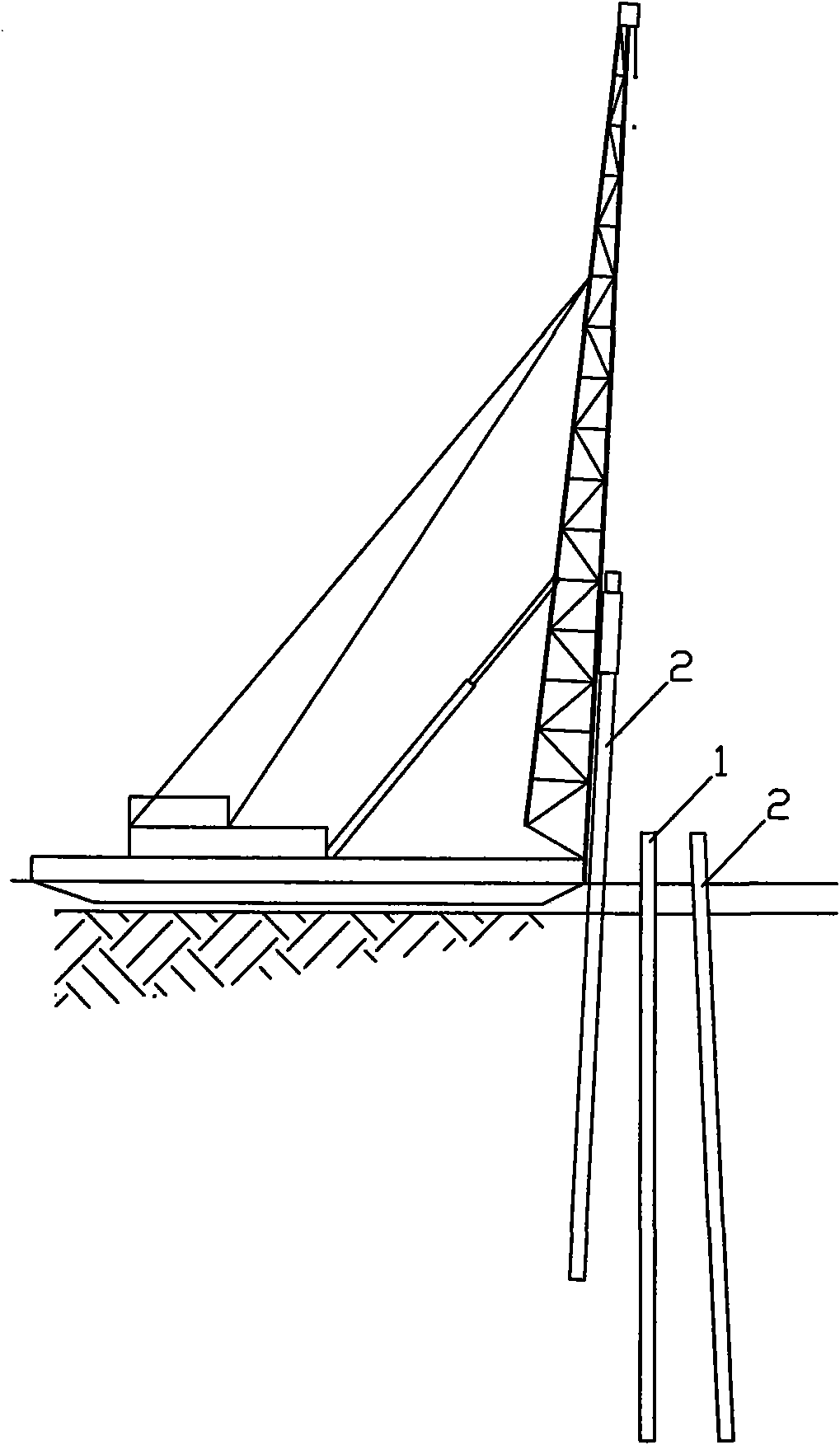

[0037] see see Figure 2a ~ Figure 2f , a structural installation and construction method of the water wind power generation tower foundation and structure of the present invention.

[0038] 1) Use a piling boat and a pile driver to drive a central pile 1 into a predetermined position in the water. The central pile 1 is a steel pipe pile with a diameter of 1470mm and a wall thickness of 20mm. The central pile 1 is a vertical pile with a total length of 60m, of which the length is 52m below the mud surface, 3m in the water, and 5m above the water;

[0039] 2) Drive four satellite piles 2 around the central pile 1 by using a piling ship and a pile driver. The satellite piles 2 are all oblique piles with a total length of 60m. The inclination ratio of the horizontal direction and the vertical direction is 1:20. Satellite piles 2 are all steel pipe piles with a diameter of 1470mm and a wall thickness of 20mm;

[0040] 3) A small construction ship is moored to set a central stru...

Embodiment 2

[0049] see Figure 3a ~ Figure 3f , the installation and construction method of another structural form of the foundation and structure of the floating wind power generation tower of the present invention.

[0050] 1) Use a piling boat and a pile driver to drive a central pile 1 into a predetermined position in the water. The central pile 1 is a steel pipe pile with a diameter of 1470mm and a wall thickness of 20mm. The central pile 1 is a vertical pile with a total length of 60m, of which the length is 52m below the mud surface, 3m in the water, and 5m above the water.

[0051] 2) Drive four satellite piles 2 around the central pile 1 by using a piling ship and a pile driver. The satellite piles 2 are all oblique piles with a total length of 60m. The inclination ratio of the horizontal direction and the vertical direction is 1:20. The satellite piles 2 are all steel pipe piles with a diameter of 1470mm and a wall thickness of 20mm.

[0052] 3) A small construction ship is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com