Returned alumina conveying distribution structure

A configuration structure, alumina technology, applied in the field of alumina configuration structure, can solve the problems of excessive purification system, damage to raw material delivery balance, environmental hazards around the enterprise, etc., to achieve the effect of ensuring emission targets

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

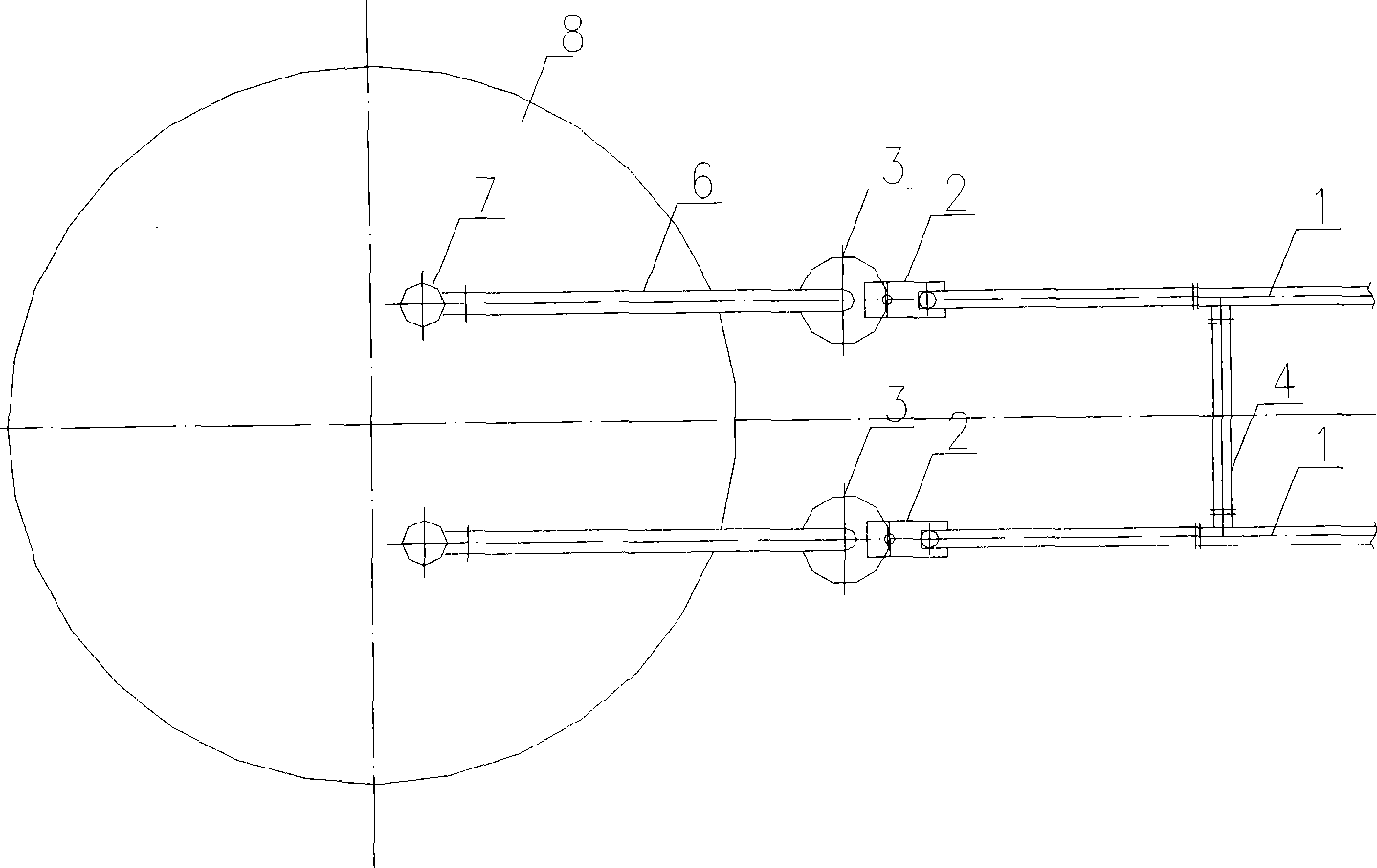

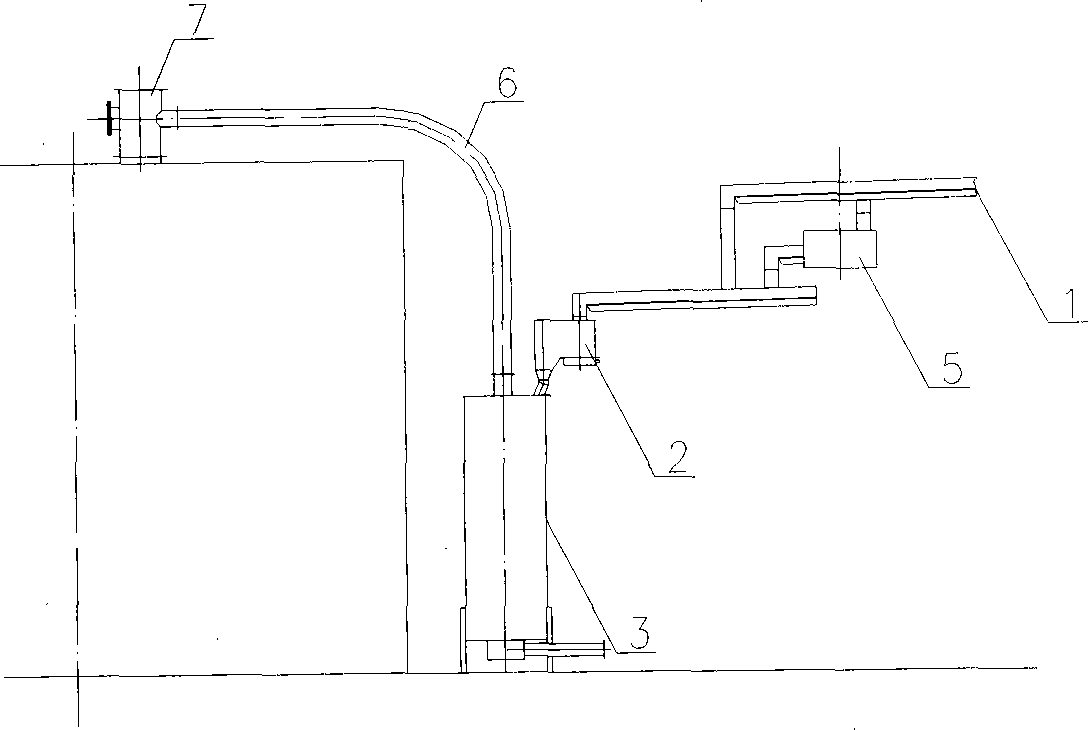

[0015] Such as figure 1 The conveying arrangement structure of returning alumina of the present invention shown in the present invention comprises two return chutes 1, and the two return chutes are respectively connected with the material lifting device 3, and the material lifting device 3 is a pneumatic lifter, and the return chute 1 is provided with Connect the chute 4, and set a miscellaneous removal box 2 between the return chute 1 and the material lifting device 3. The miscellaneous removal box has the function of separating impurities; the material lifting device 3 is connected to the top of the storage bin 8 through the feeding pipe 6, and the feeding pipe A feeder 7 is provided between 6 and the top of the storage bin 8 .

Embodiment 2

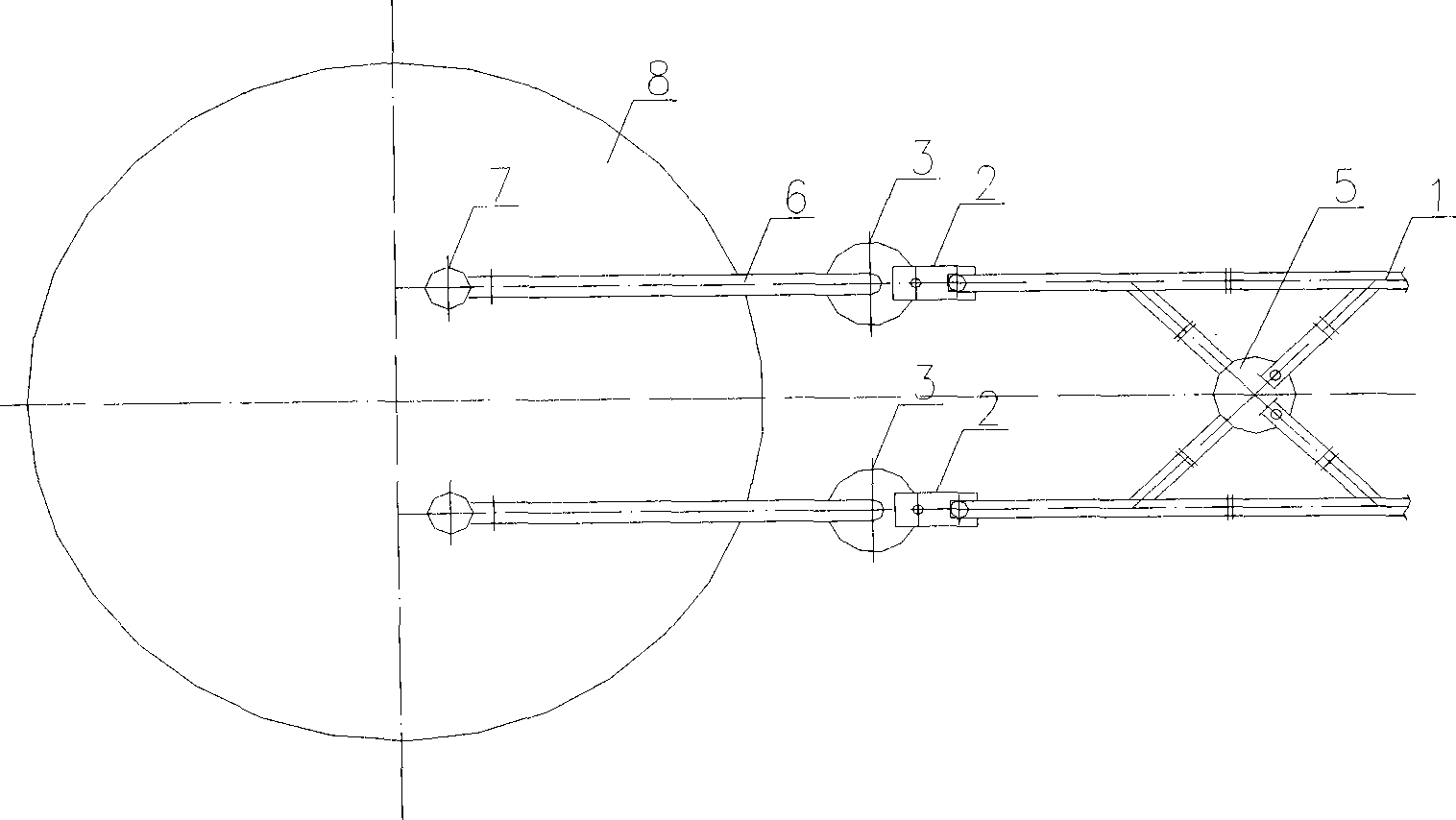

[0017] In Embodiment 1, a diverter 5 is provided between the two return chutes 1, and the diverter can change the flow direction of the alumina material; the material lifting device is a pressure tank lifting device, and the others are the same as in Embodiment 1.

Embodiment 3

[0019] There are three return chutes in Embodiment 1, and a connection chute 4 is provided between the three return chutes, and the others are the same as in Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com