Production method of natural equivalent anisic aldehyde

An anisaldehyde and production method technology, applied in the field of spice production, can solve the problems of increasing equipment cost and raw material cost, difficult disposal of waste acid, large amount of sulfuric acid, etc., and achieve low production cost, high degree of naturalness, and less waste acid Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

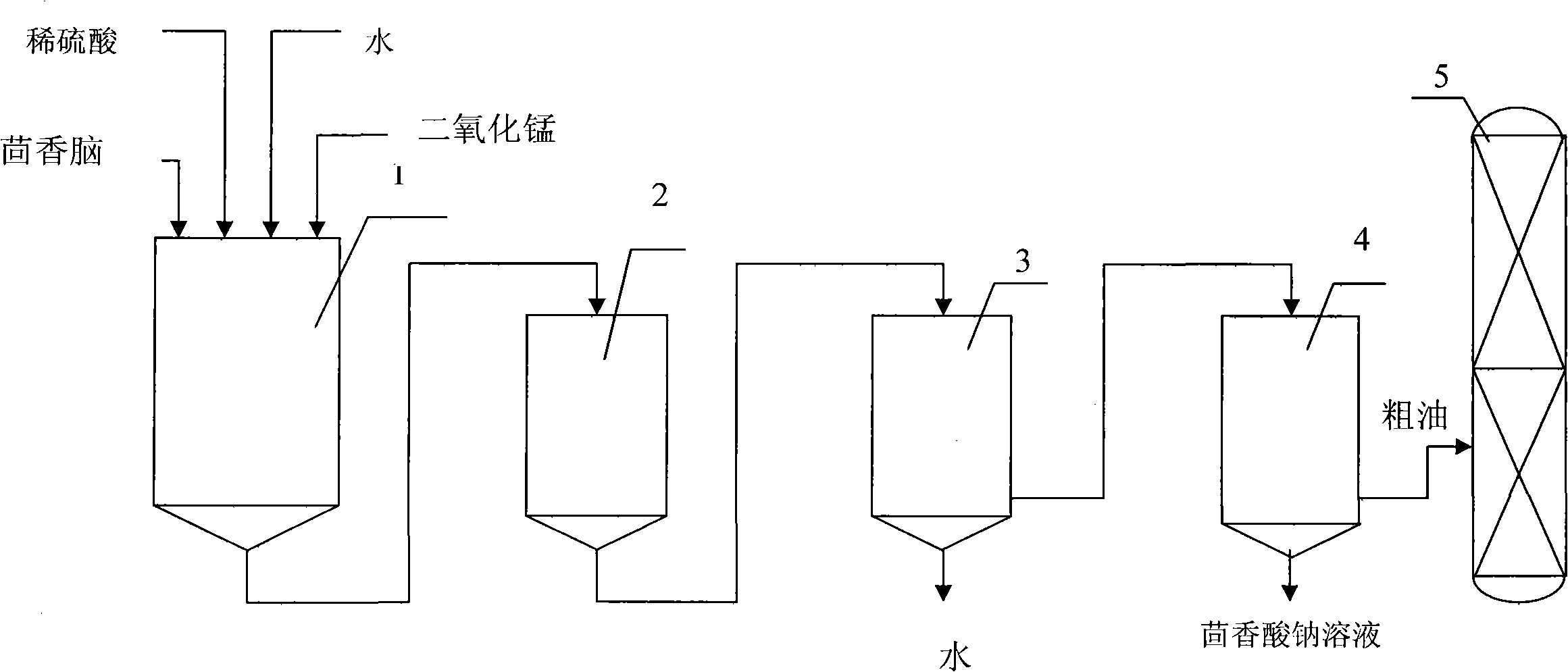

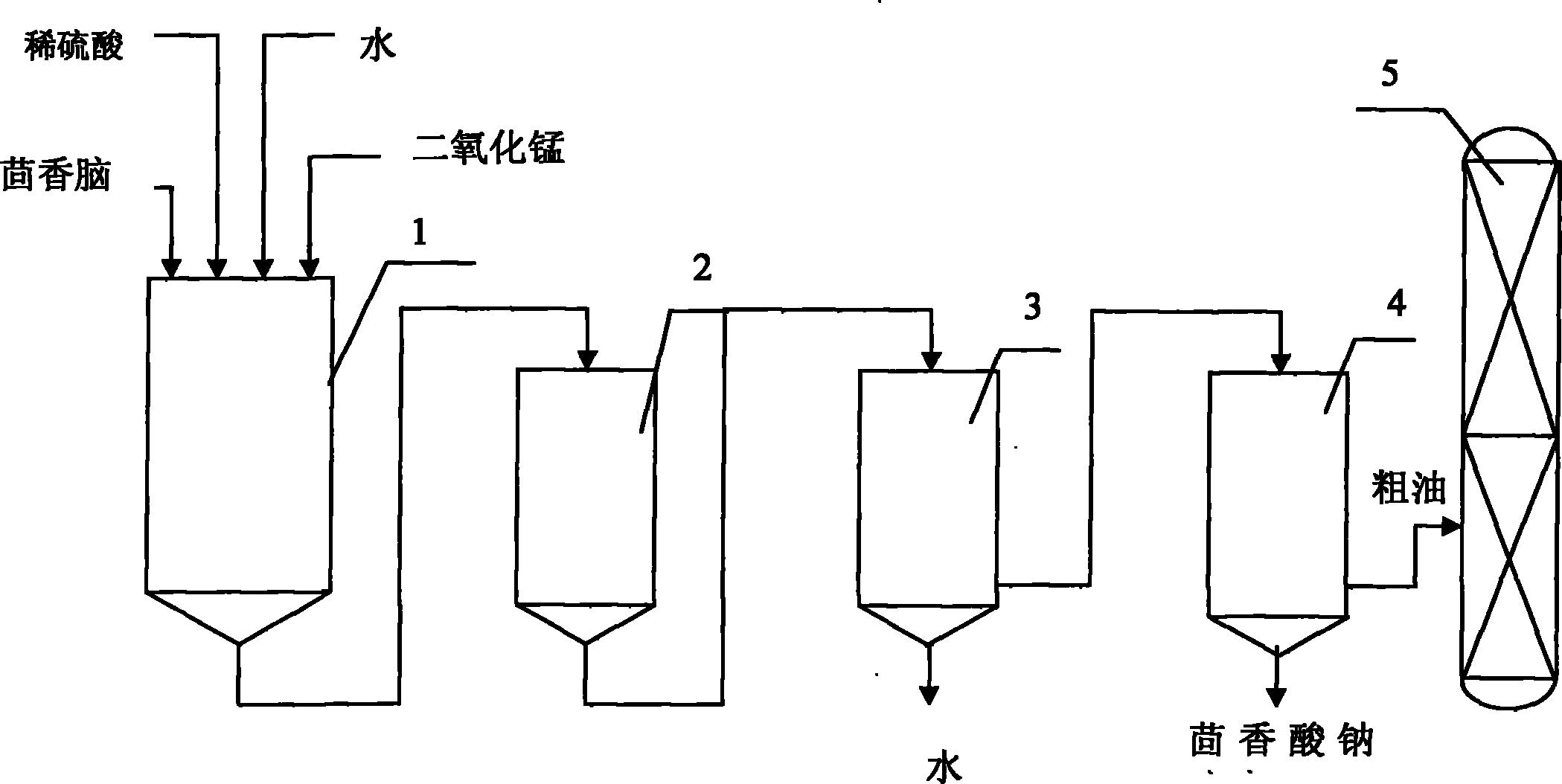

Method used

Image

Examples

Embodiment 1

[0027] Put 20kg of anethole, 120kg of dilute sulfuric acid, 60kg of manganese dioxide and 80kg of water into the reactor while stirring, slowly raise the temperature to 120°C within 10 minutes, and react at a constant temperature for 120 minutes. After the reaction is over, the reaction materials are put into a pressure filter tank while it is hot for pressure filtration. It takes about 90 minutes, the filtrate is discharged from the bottom of the tank, and the filter residue is taken out from the top of the tank. The filtrate discharged from the bottom of the pressure filter tank enters the liquid separation tank through the pipeline to stand for stratification, and the sinking water is drained regularly, and the intermediate product anisealdehyde crude product enters the neutralization tank through the pipeline from the bottom of the liquid separation tank. Since the obtained crude anisaldehyde is acidic because it contains part of sulfuric acid, the pH value of the solution ...

Embodiment 2

[0029] Put 20kg of anethole, 115kg of dilute sulfuric acid, 59kg of manganese dioxide and 80kg of water into the reactor while stirring, slowly raise the temperature to 120°C within 10 minutes, and react at a constant temperature for 110 minutes. After the reaction is over, the reaction materials are put into a pressure filter tank while it is hot for pressure filtration. It takes about 100 minutes, the filtrate is discharged from the bottom of the tank, and the filter residue is taken out from the top of the tank. The filtrate discharged from the bottom of the pressure filter tank enters the liquid separation tank through the pipeline to stand for stratification, and the sinking water is drained regularly, and the intermediate product anisealdehyde crude product enters the neutralization tank through the pipeline from the bottom of the liquid separation tank. Since the obtained crude anisaldehyde is acidic because it contains part of sulfuric acid, the pH value of the solution...

Embodiment 3

[0031] Put 20kg of anethole, 114kg of dilute sulfuric acid, 58kg of manganese dioxide and 80kg of water into the reactor while stirring, slowly raise the temperature to 130°C within 10 minutes, and react at a constant temperature for 120 minutes. After the reaction is over, the reaction materials are put into a pressure filter tank while it is hot for pressure filtration. It takes about 90 minutes, the filtrate is discharged from the bottom of the tank, and the filter residue is taken out from the top of the tank. The filtrate discharged from the bottom of the pressure filter tank enters the liquid separation tank through the pipeline to stand for stratification, and the sinking water is drained regularly, and the intermediate product anisealdehyde crude product enters the neutralization tank through the pipeline from the bottom of the liquid separation tank. Since the obtained crude anisaldehyde is acidic because it contains part of sulfuric acid, the pH value of the solution ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com