Beverage bottle cleaning and sterilizing integrated machine

A technology of cleaning and disinfection and an all-in-one machine, which is applied in the direction of cleaning hollow objects, cleaning methods and utensils, chemistry, etc., can solve the problems of inability to complete cleaning and disinfection work continuously, low utilization rate of equipment, low work efficiency, etc., and achieve simple structure and equipment The effect of high utilization rate and reduction of manpower

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

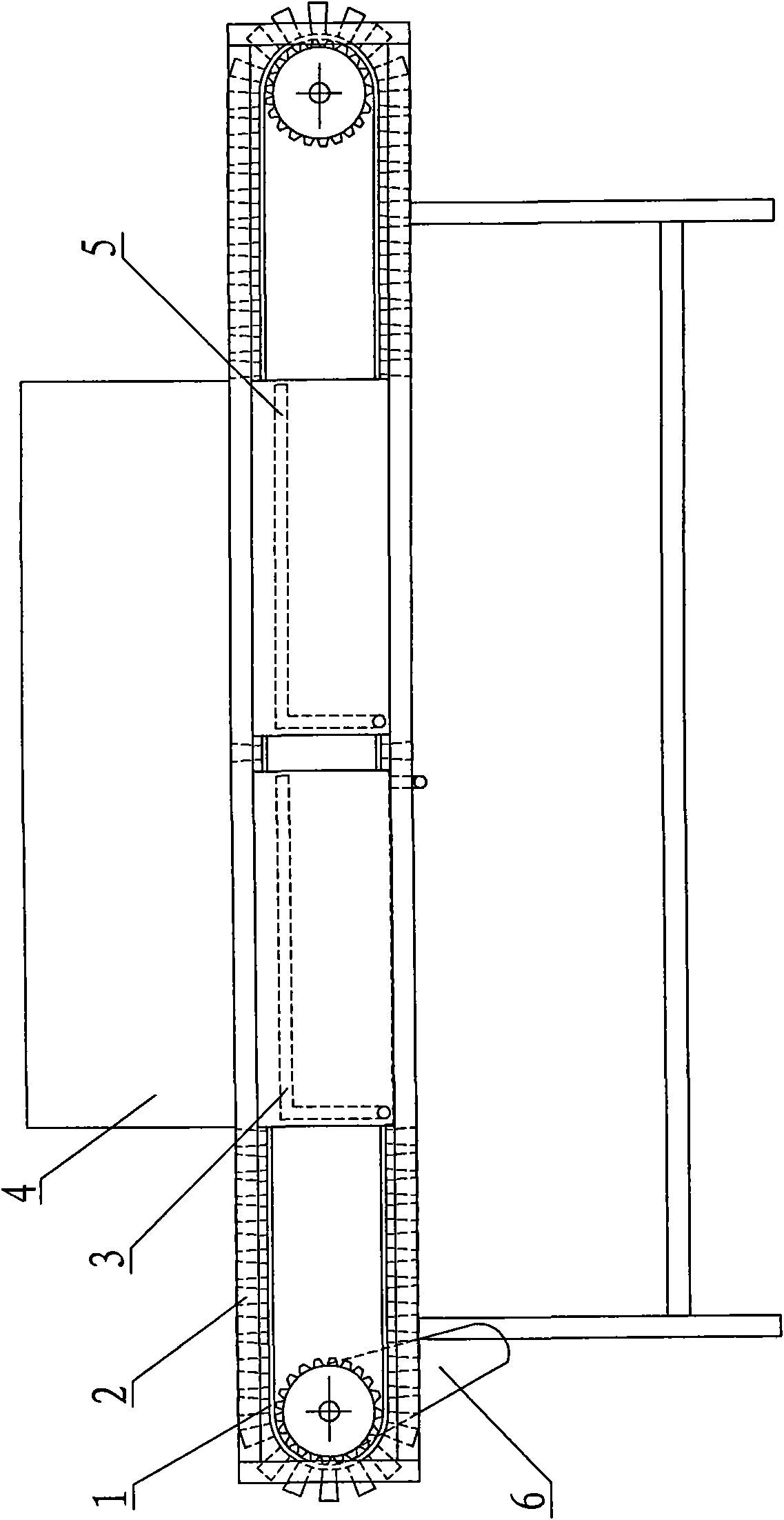

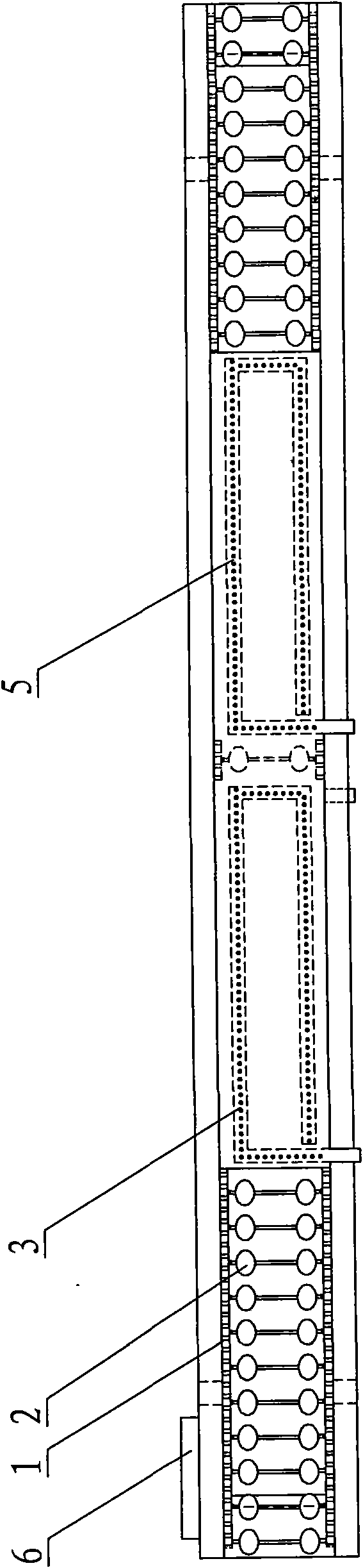

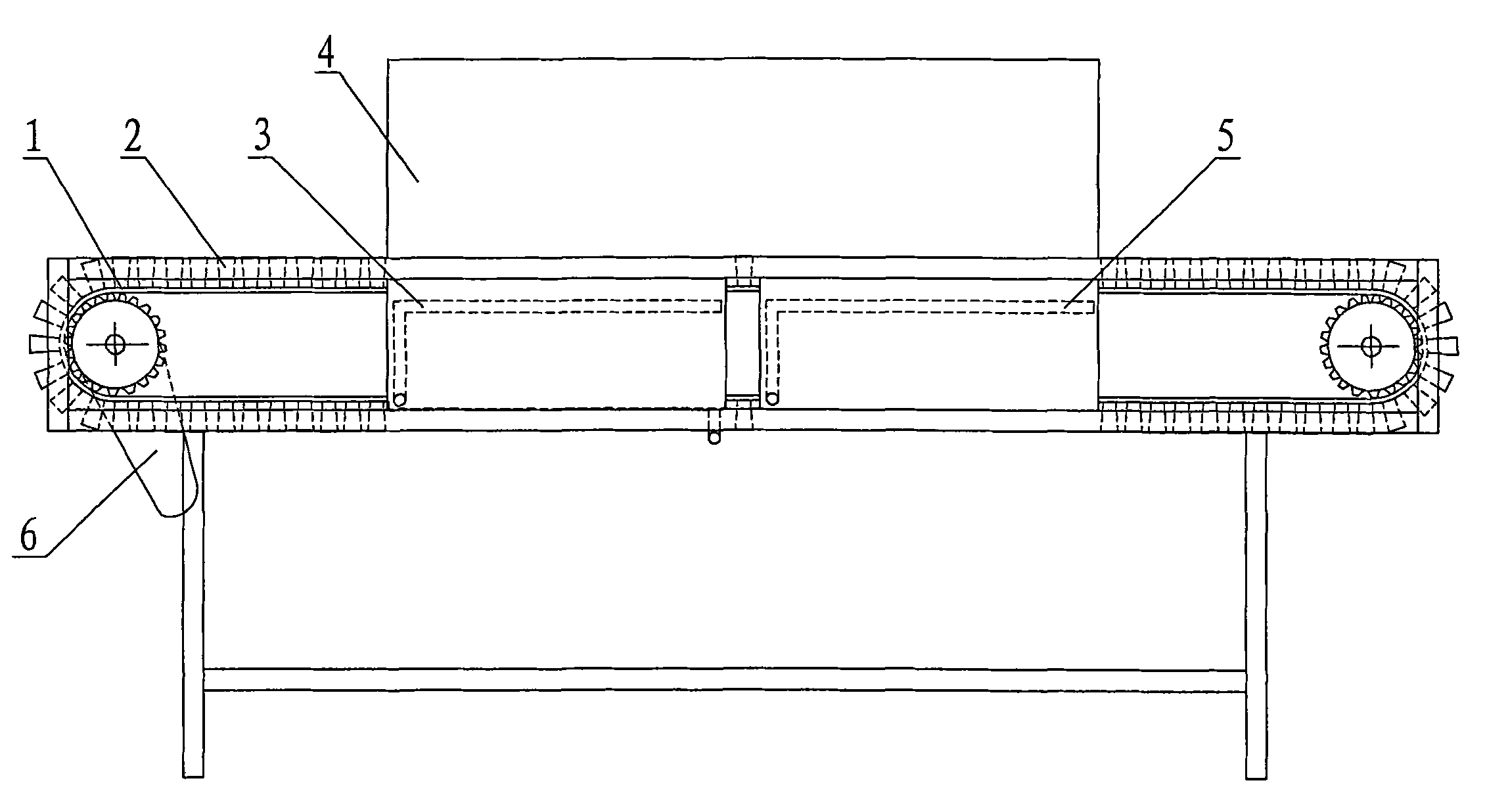

[0015] Example 1. refer to figure 1 , figure 2 . An all-in-one machine for washing and disinfecting beverage bottles, including a frame, on which a conveyor belt 1 is arranged, driven by a motor 6, on which several bottle holders 2 are arranged, and below the conveyor belt 1, disinfection tubes are sequentially arranged The road 3 and the cleaning pipeline 5, the disinfection pipeline 3 and the cleaning pipeline 5 are respectively provided with several spray holes or nozzles, and the disinfection pipeline 3 is connected with a water pump.

[0016] During implementation, the beverage bottle is put upside down into the bottle holder 2, the cleaning pipeline 5 is connected to the tap water pipe, the water pump is turned on, the motor 6 is started, the beverage bottle moves forward along with the conveyor belt 1, and when it reaches the bottom of the disinfection pipeline 3, The disinfectant water comes out from the spray hole or nozzle of the disinfection pipeline 3 through t...

Embodiment 2

[0017] Example 2. In the all-in-one machine for washing and disinfecting beverage bottles described in Embodiment 1, a travel switch is installed on the frame, and the travel switch is connected to the water pump through a signal line. During implementation, the water pump is controlled by controlling the travel switch, so that the water pump can be switched on and off as required.

Embodiment 3

[0018] Example 3. In the all-in-one machine for washing and disinfecting beverage bottles described in Example 1, two rows of bottle holders 2 are arranged in parallel along the direction of the conveyor belt 1 on the conveyor belt 1, and the bottle holders 2 in the same row are arranged at equal intervals.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com