Blade body sectional surface design method for die forging blade

A technology of airfoil profile and design method, applied in calculation, special data processing applications, instruments, etc., can solve the problem that there is no relevant report on CAD/CAM research work, the airfoil profile has not been optimized, and the airfoil shape has not been established. Face mathematical models and other issues to achieve the effect of shortening the product development and production cycle, realizing resource sharing and digital manufacturing, and having the effect of inheritance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

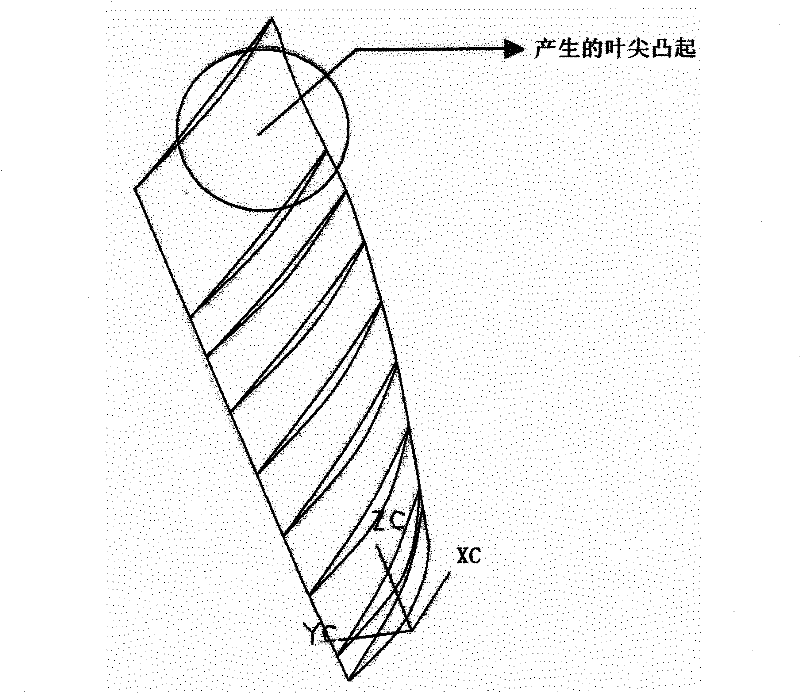

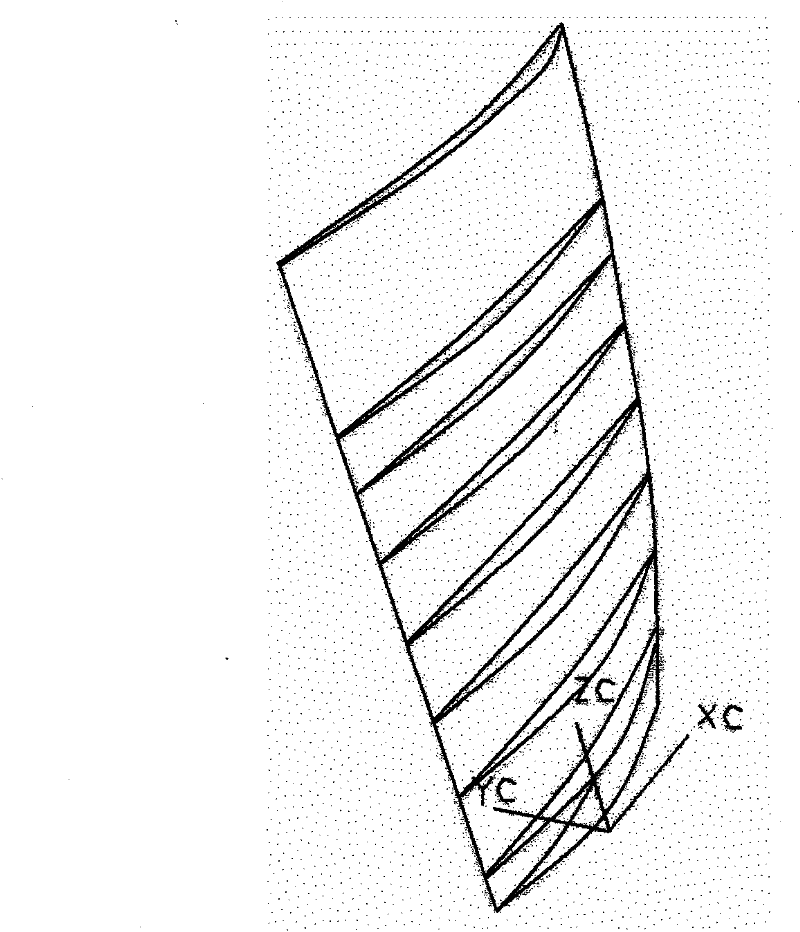

[0032] A die-forging blade airfoil profile design method, in which the die-forging blade airfoil profile design is sequentially performed according to the following requirements:

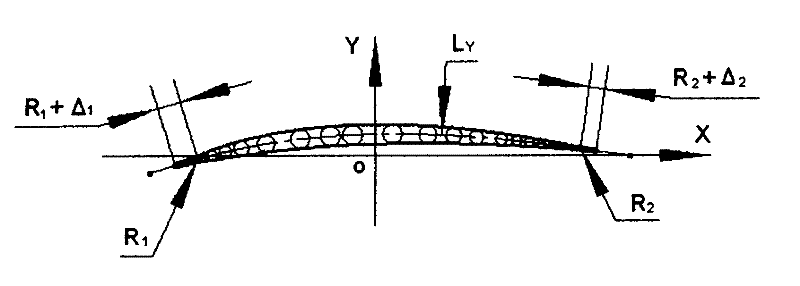

[0033] (1) First, according to the coordinate value of the airfoil surface point of the blade part, the mathematical model of the airfoil surface line is established; (2) according to the mathematical model, the inscribed circle of the air inlet and exhaust edges is obtained; (3) ) Optimizing the edge radius or molding line to make the molding surface accurate and smooth; (4) Establishing a mathematical model of the blade airfoil forging on this basis, and adding the allowance.

[0034] The method for designing the airfoil profile of the die-forged blade also includes the following specific requirements:

[0035] In step (1), there are the following specific requirements: according to the coordinate values of the airfoil surface points of the blade parts, the mathematical model of the airfoil surf...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com