Control method and control system for finished product cabin material conveying trolley of asphalt mixing station

A material transport trolley and asphalt mixing technology, which is applied in the control/adjustment system, vehicle position/route/height control, non-electric variable control, etc. Component detection and control function failure, etc., to achieve the effect of improving accuracy and reducing the probability of accidents

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The specific embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

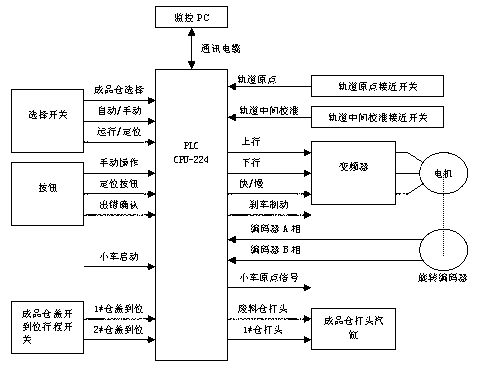

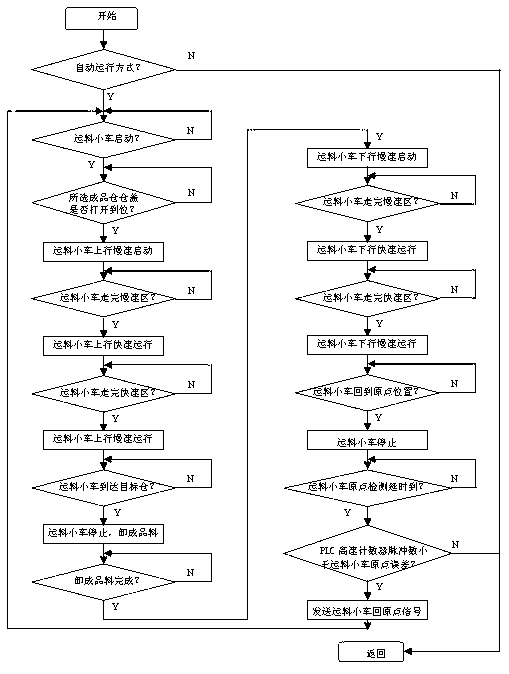

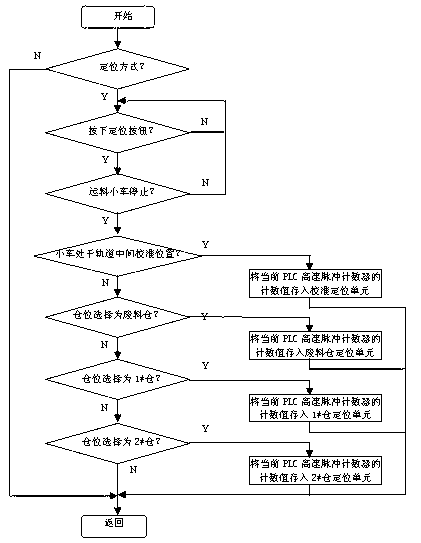

[0037] figure 1 The composition of the control system of the present invention is shown. Such as figure 1 As shown, the main body of the control system of the present invention is composed of a main controller, a motor, a frequency converter, an incremental rotary encoder, a track origin proximity switch, and a track middle calibration proximity switch.

[0038] The main controller is the control core of the whole system. In this embodiment, the main controller adopts Siemens CPU-224 PLC. The motor is used to pull the movement of the finished product warehouse transport trolley. The frequency converter is connected to the main controller and the motor, and is used to drive the motor under the control of the main controller to pull the finished product warehouse material trolley to achieve up and down slow / fast forward rotation, slow / fast ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com