Air spring for regulating static rigidity through volume and regulating dynamic rigidity through auxiliary air chamber

A technology that assists air chambers and air springs, applied in springs, springs/shock absorbers, gas shock absorbers, etc., can solve the problem that the static stiffness of the air spring cannot be matched and adjusted individually, and the dynamic stiffness of the air spring cannot follow the dynamic load adjustment. , Affect the comfort of the passengers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

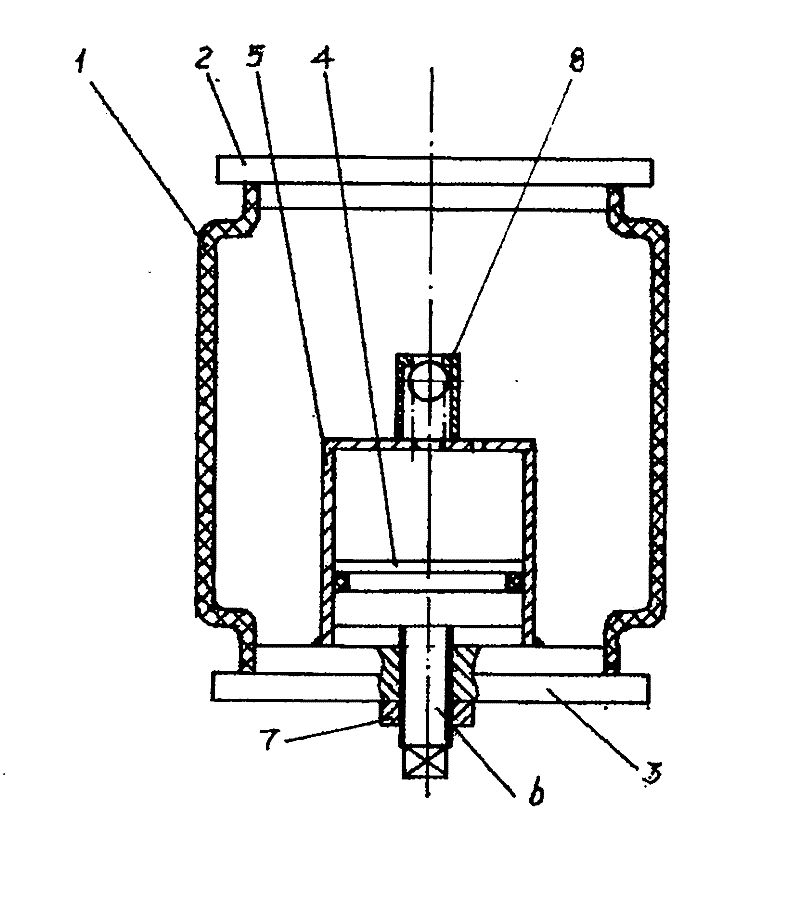

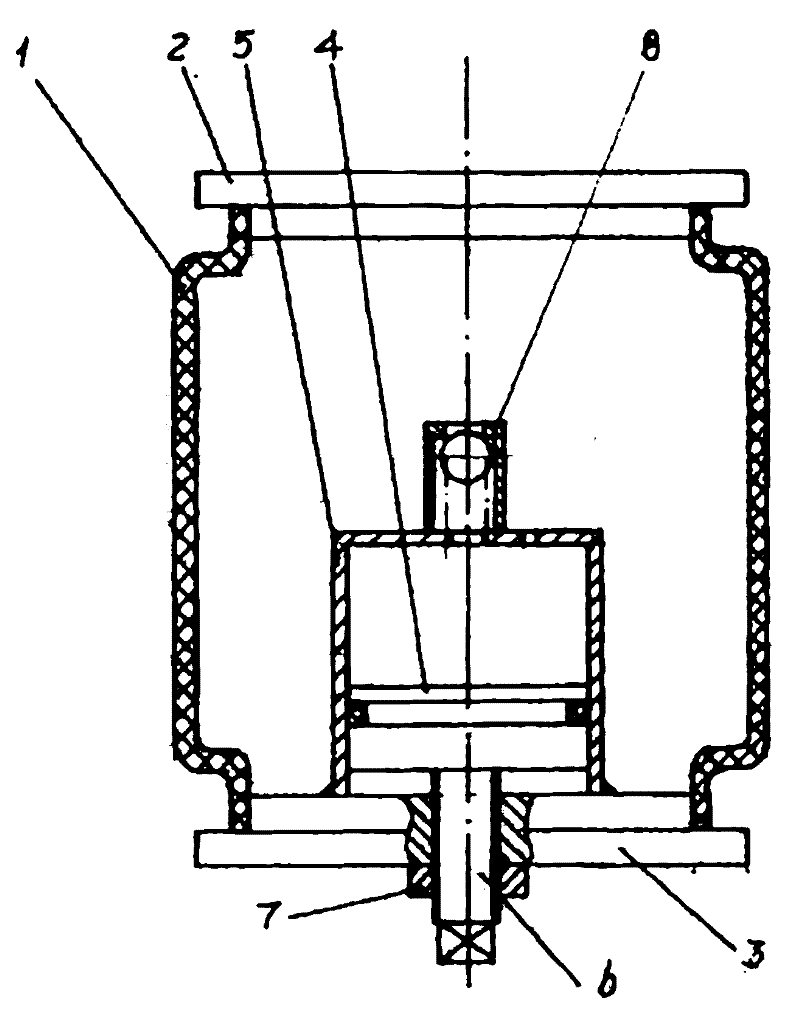

[0008] The specific embodiment of the present invention is: the static stiffness adjustment method of the present invention: loosen the lock nut 7, turn the adjusting bolt 6 to push the piston 4 to move upward in the auxiliary air chamber 5, and the upward movement of the piston 4 in the auxiliary air chamber 5 Moving has just enlarged the volume between the piston 4 bottom surface and the auxiliary air chamber 5 bottoms, which has reduced the equivalent volume of the air bag 1 to accommodate the gas, and has increased the static stiffness of the air spring. Reversely turning the adjusting bolt 6 will make the adjusting bolt 6 move down, and the piston 4 will move downward in the auxiliary air chamber 5 due to the gas pressure in the air bag 1, reducing the distance between the bottom surface of the piston 4 and the bottom of the auxiliary air chamber 5. The volume between them increases the equivalent volume of gas contained in the airbag 1; thereby achieving the purpose of lo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com