Mechanical supercharger structure with speed-increasing and shock-absorbing functions

A supercharger and functional technology, applied in the direction of mechanical equipment, machines/engines, engine components, etc., can solve the problems of limited speed ratio of supercharger and limited engine supercharging effect, so as to improve supercharging effect and increase Large coincidence coefficient, the effect of improving the bearing capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] Below with reference to the accompanying drawings, through the description of the embodiments, the specific embodiments of the present invention, such as the shape, structure, mutual position and connection relationship between the various parts, the role and working principle of the various parts, etc., will be further described. Detailed instructions:

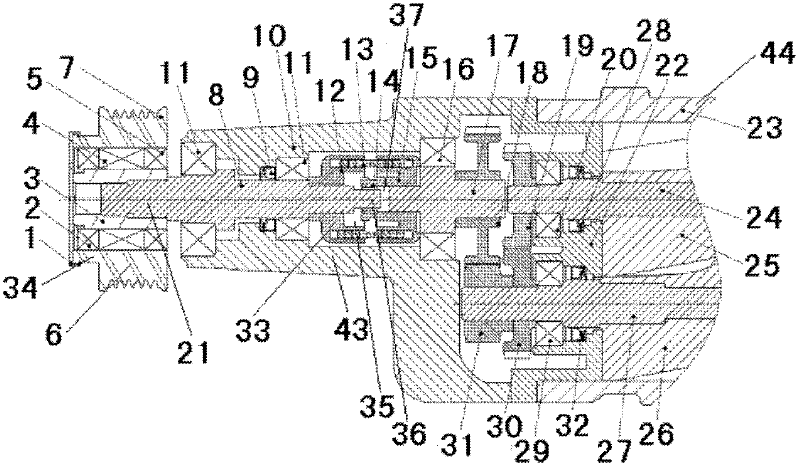

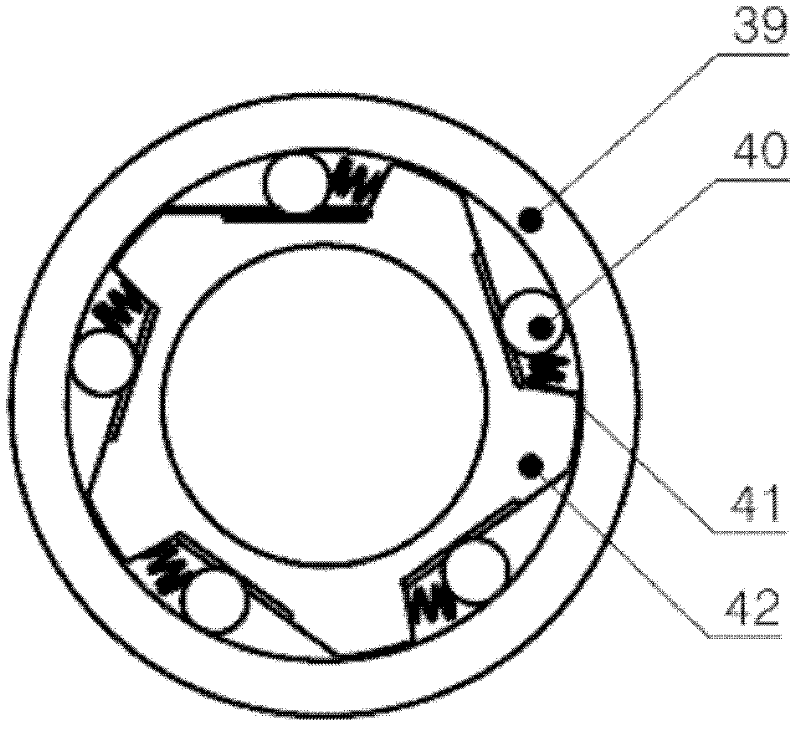

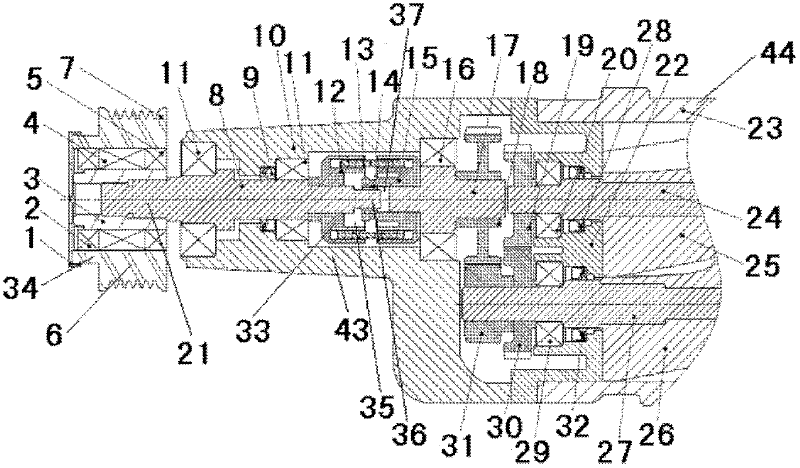

[0020] as attached figure 1 , attached figure 2 As shown, the present invention is a supercharger structure, including a pulley assembly 6, a front cover assembly 43, and a bearing plate assembly 44. The front cover assembly 43 is provided with an input on the front cover 10. Shaft 8 and pulley assembly 6 are installed on the input shaft front end 21, bearing plate assembly 44 is provided with drive shaft 27 and driven shaft 24 in bearing plate 22, and input gear 18 and Output gear 31, through input gear 18 and output gear 31 engagement between intermediate shaft 17 and driving shaft 27, driving gear 30 and driven g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com