Connecting element for building framework structures

A frame structure and connector technology, applied in building construction, construction, etc., can solve problems such as large waste of building materials, reduce installation efficiency, and improve installation difficulty, and achieve the goal of reducing construction waste, saving installation time, and reducing labor intensity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0112] like figure 1 As shown, the connector of the building frame structure is the connector of the bottom building frame structure, including the connector body 1 of the integrally formed building frame structure, and an upper column plug joint that needs to be plugged and fixed with the end of the column in the vertical horizontal direction. 2. Two beams that directly support parallel to the horizontal plane, horizontal support joints 3 and 4 that are fixedly connected to the ends of the beams.

[0113] A supporting column horizontal plane 5 directly supporting the column is provided above the connector body 1 of the building frame structure. The upper column plug connector includes symmetrical U-shaped protrusions 6 and 7 extending vertically upward from the horizontal plane of the support column, with openings facing both sides, and horizontally side by side. The distance between the opposing surfaces of the U-shaped convex portion 6 and the U-shaped convex portion 7 is ...

Embodiment 2

[0117]like figure 2 As shown, different from Embodiment 1, there are three horizontal support joints, namely, horizontal support joint 20, horizontal support joint 21, and horizontal support joint 22, and horizontal support joint 20, horizontal support joint 21, and horizontal support joint 22 are perpendicular to each other. , into a T-shape.

Embodiment 3

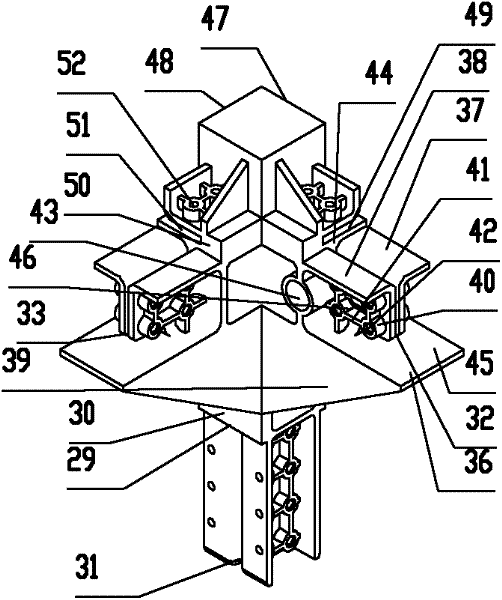

[0119] like image 3 As shown, the connector of the building frame structure is the connector of the bottom building frame structure, including the connector body 23 of the integrally formed building frame structure, and an upper column plug joint that needs to be plugged and fixed with the end of the column in the vertical horizontal plane direction. 24. Four cross-shaped beams that directly support parallel to the horizontal plane, horizontal support joints 25, 26, 32, and 33 that are fixedly connected to the ends of the cross beams. The bottom surface of the connector body 20 of the building frame structure is a plane. The structure of the upper column plug connector 24 and the four horizontal support connectors is the same as that of Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com