High-efficiency internal recycle ceramic-adhered biomembrane nitration reactor

A technology for nitrification reactors and attached organisms, which is applied in the field of high-efficiency internal circulation ceramic attached biofilm nitrification reactors, which can solve problems such as the inability to accumulate high-concentration biological cells, limit the efficiency of nitrification reactors, and slow growth of nitrifying bacteria, and achieve compact structure , high volumetric conversion efficiency, and good biological nitrification performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

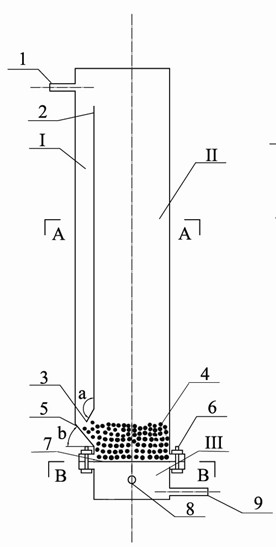

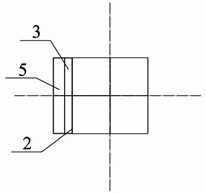

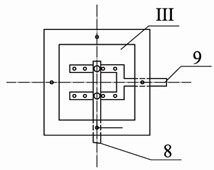

[0012] like figure 1 , 2 As shown in , 3, the high-efficiency internal circulation ceramic attached biofilm nitrification reactor is provided with a sedimentation circulation area I, an aeration reaction area II and a water distribution area III; Plate 3, inclined bottom plate 5; water outlet 1 is located at the top of the sedimentation circulation area I, and its position is higher than the isolation plate 2, and the isolation plate 2 divides the sedimentation circulation area I and the aeration reaction area II into two independent areas; the isolation plate 2 The bottom is connected with an air bubble baffle 3, whose width is the same as that of the isolation plate 2; the angle between the isolation plate 2 and the air bubble baffle 3 is 150°, and there is a gap between the air bubble baffle 3 and the inclined bottom plate 5, and the aeration reaction Zone II is filled with ceramic particles 4 and equipped with wire mesh panels 7; water distribution and gas distribution zo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com