Hydraulic automatic pin pulling device

An automatic and hydraulic technology, applied in the direction of metal processing, metal processing equipment, manufacturing tools, etc., can solve the problems of large volume and weight, low work safety factor, large pin shaft, etc., to reduce workload, reduce investment, and tighten powerful effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

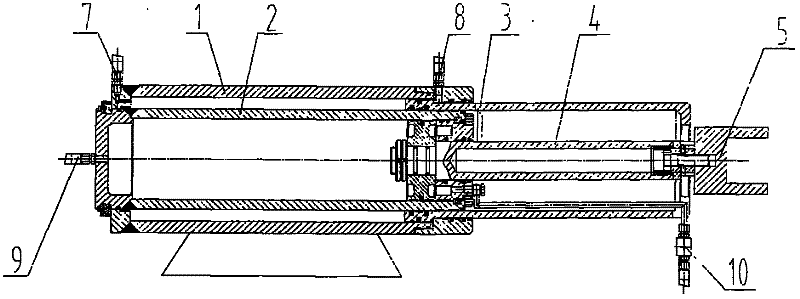

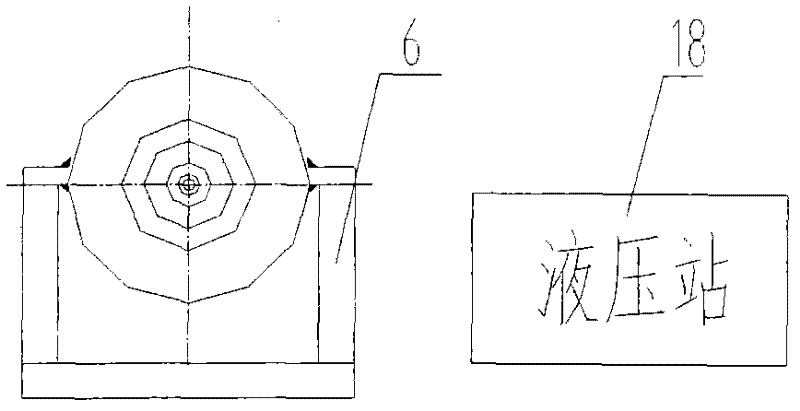

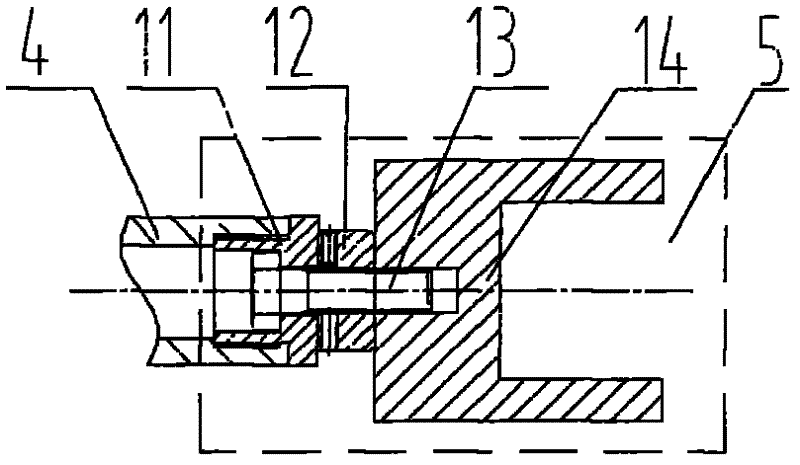

[0012] The hydraulic automatic pin pulling device of the present invention, its preferred embodiment is as follows figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 As shown, the hydraulic automatic pin pulling device includes a supporting cylinder body 1, a pin pulling cylinder body 2, a supporting cylinder piston rod 3, a pin pulling cylinder piston rod 4 and a bolt connector 5.

[0013] The pin pulling cylinder body 2 is located inside the supporting cylinder body 1, and the supporting cylinder body 1 and the pin pulling cylinder body 2 are concentrically nested and assembled.

[0014] The supporting cylinder piston rod 3 adopts a closed hollow shaft design, the pin pulling cylinder piston rod 4 is located inside the supporting cylinder piston rod 3, and the pin pulling cylinder piston rod and the supporting cylinder piston rod are concentrically nested and assembled.

[0015] The top of the pin pulling cylinder piston rod 4 is provided with an internally threaded...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com