Stamping method for producing precise HDMI (high definition multimedia interface) terminals

An interface terminal, high-definition technology, applied in the field of cold stamping, can solve the problems of leaning together, terminal short circuit, easy bending of pins, etc., to avoid bending deformation, improve production efficiency, and save costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

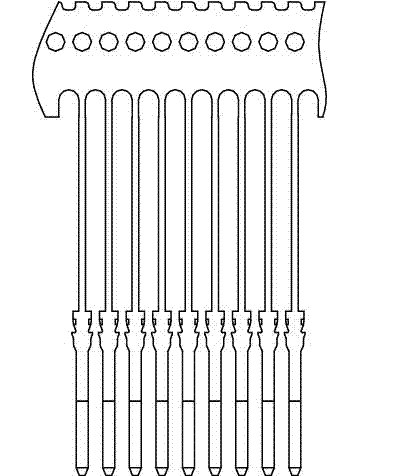

[0023] combine figure 1 Fig. 3 illustrates a kind of stamping method of producing HDMI precision high-definition interface terminal of the present invention, comprises the following steps:

[0024] (1) Blanking: punching pre-processed metal sheets to obtain blanking products;

[0025] (2) Forming: Bending and forming the blanked finished product after blanking to make interface terminals;

[0026] (3) Demolding: Make the interface terminal out of the stamping die.

[0027] The blanking step is completed sequentially by rough cutting and fine cutting.

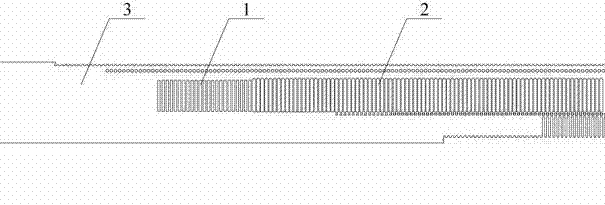

[0028] On the pre-processed metal sheet, the center lines of the rough-cut punching hole 1 of the rough-cut blanking stamping and the fine-cut punching hole 2 of the fine-cut blanking stamping coincide. And the area of the rough-cut punching hole 1 is smaller than the area of the fine-cut punching hole 2 .

[0029] The stamping die is composed of a matching punch and a die, and the punch is fixedly connected from top to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com