Separated shoe tree structure

A separate type, shoe last technology, applied in the direction of shoe last, footwear, application, etc., can solve the problems of increasing production cost, changing sway or elongation, easy dislocation, etc., to achieve tight and stable combination, easy separation, and simplified structure Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be described in more detail below in conjunction with the accompanying drawings and embodiments.

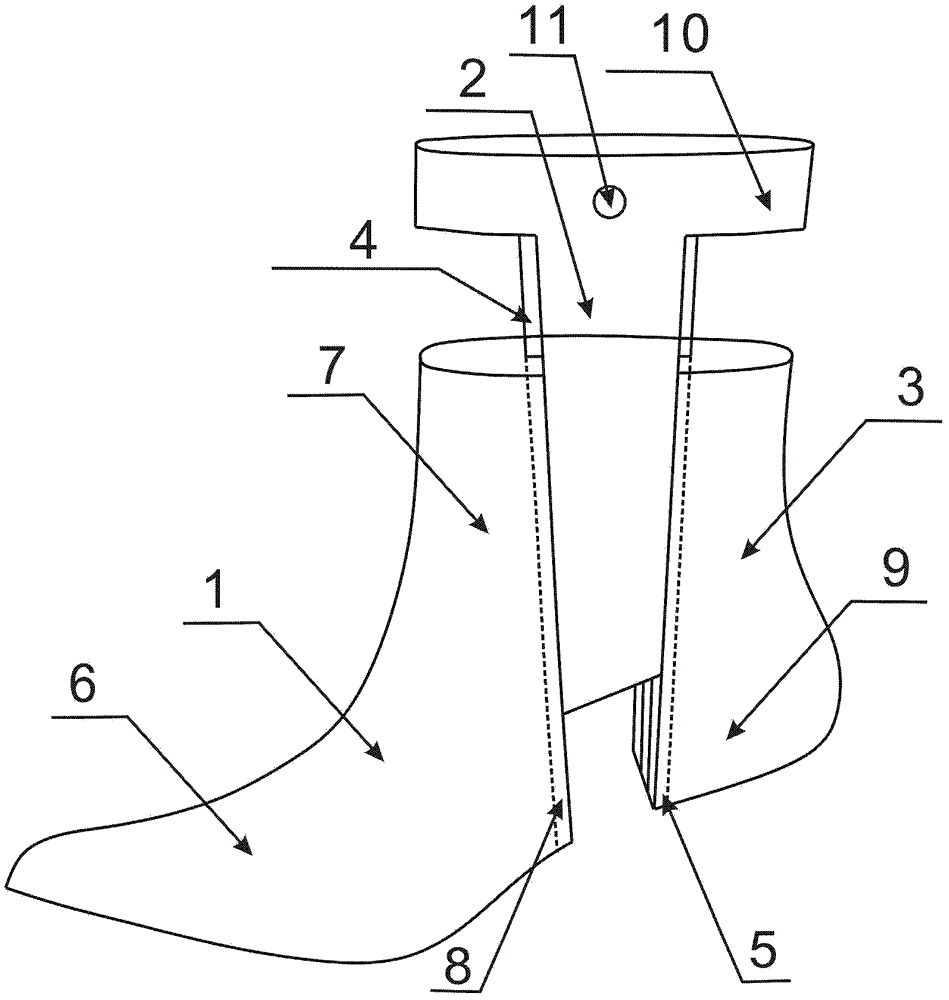

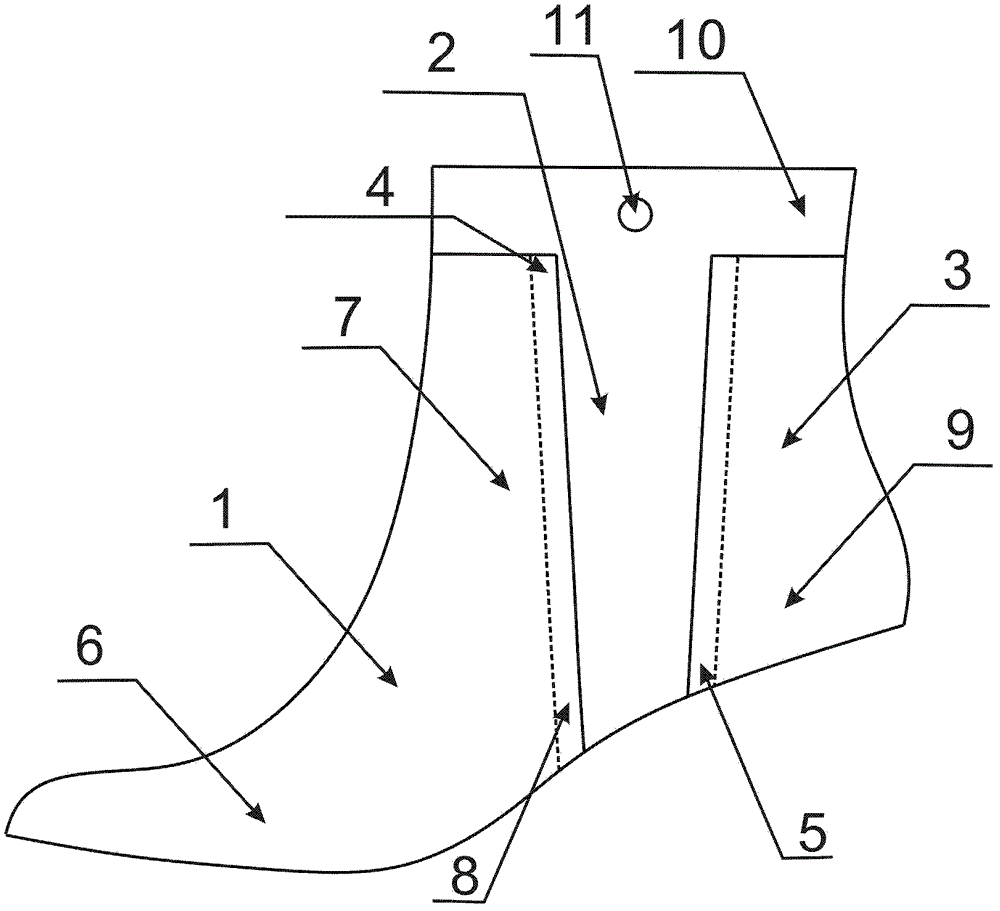

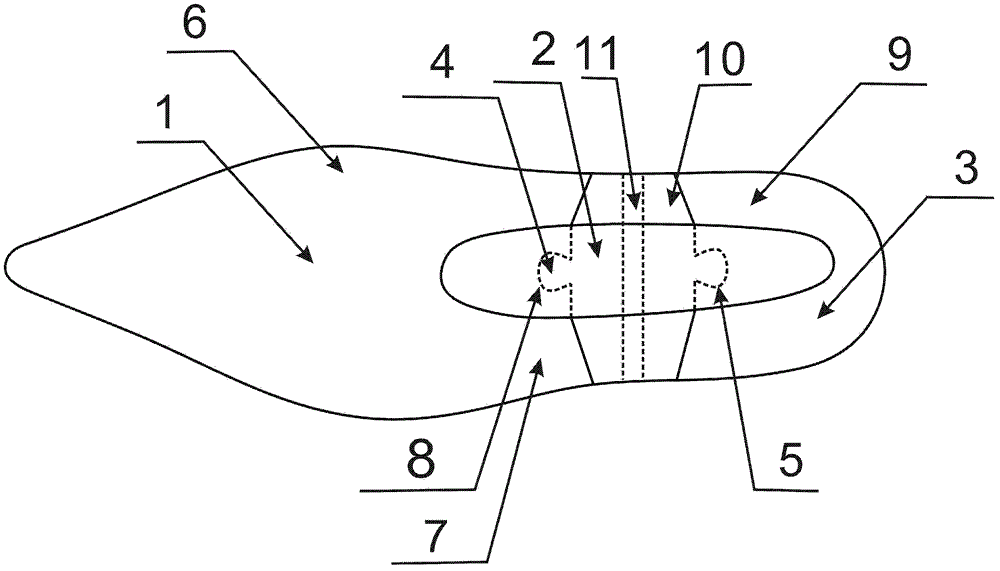

[0023] Such as figure 1 , figure 2 and image 3 Shown, the present invention is a kind of detached shoe last structure, comprises

[0024] The precursor 1, the precursor 1 is composed of a shoe last body 6 and a front half cylinder last body 7 connected with the shoe last body 6, and the first half cylinder last body 7 has a first groove 8;

[0025] The connecting body 2 is an inverted trapezoidal structure with a wide top and a narrow bottom, with a top cap 10 set on the top, protrusions 4 in the same direction as the corresponding side sides are provided on both sides, and perforations 11 are provided on the connecting body 2;

[0026] The rear body 3 is the rear half cylinder last body 9, and there is a second groove 5 on the rear half cylinder last body 9;

[0027] Among them, the protrusions 4 on both sides of the connecting body 2 coop...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com