Preparation method of beef oily essence

A beef oil and essence technology, which is applied in food preparation, application, food science and other directions, can solve the problems that the intensity of aroma and aroma cannot meet the demand, the authenticity of the product is not high, and there is no price advantage, so as to achieve outstanding cost performance and cooking sense. Strong, natural aroma effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

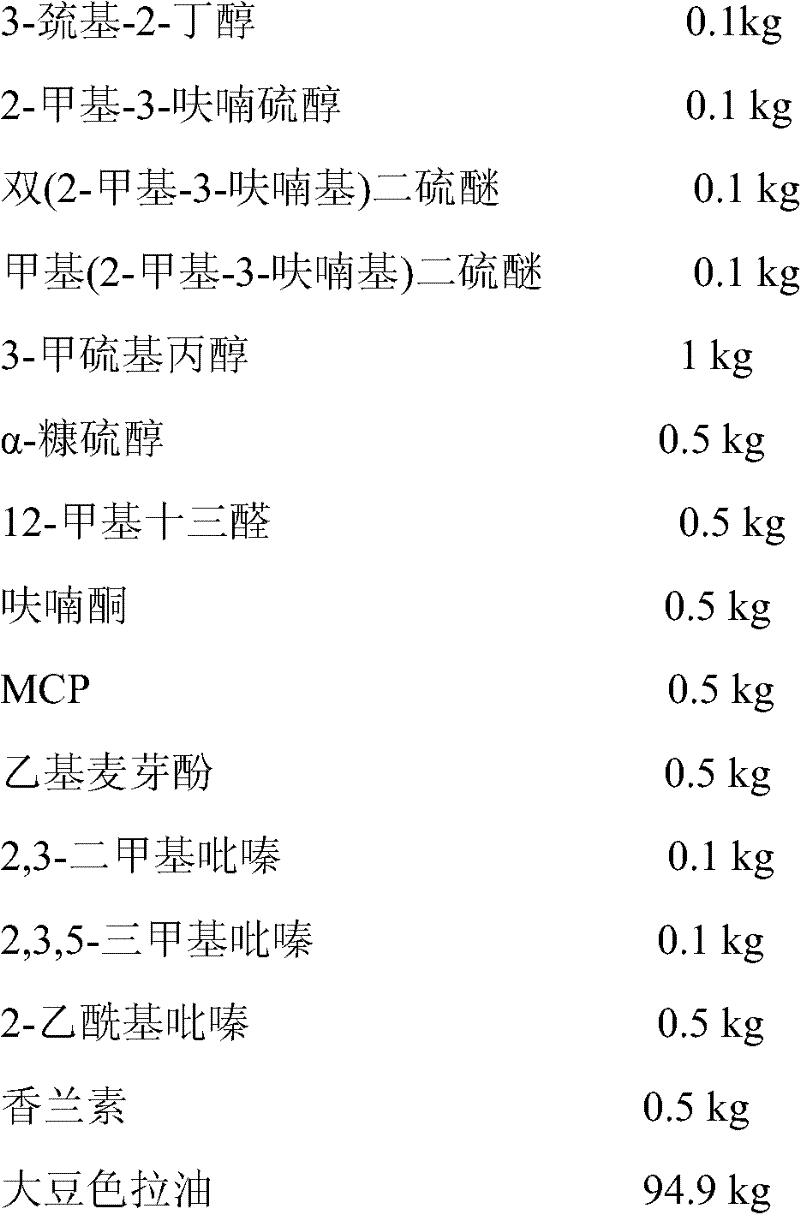

[0014] A kind of beef oily essence (production 100kg), raw material formula is:

[0015]

[0016] The production process is: heat 94.9kg of soybean salad oil to 80°C, add 0.5kg of furanone, 0.5kg of MCP, 0.5kg of ethyl maltol, 0.5kg of vanillin, and 0.5kg of 2-acetylpyrazine, and stir until completely Dissolve, add 3-mercapto-2-butanol 0.1kg, 2-methyl-3-furyl thiol 0.1kg, two (2-methyl-3-furyl) disulfide 0.1kg, methyl (2- Methyl-3-furyl) disulfide 0.1kg, 3-methylthiopropanol 1kg, α-furfuryl mercaptan 0.5kg, 12-methyl tridecanal 0.5kg, 2,3-dimethylpyrazine 0.1kg, 2,3,5-trimethylpyrazine 0.1kg, stir evenly and pack in cans.

Embodiment 2

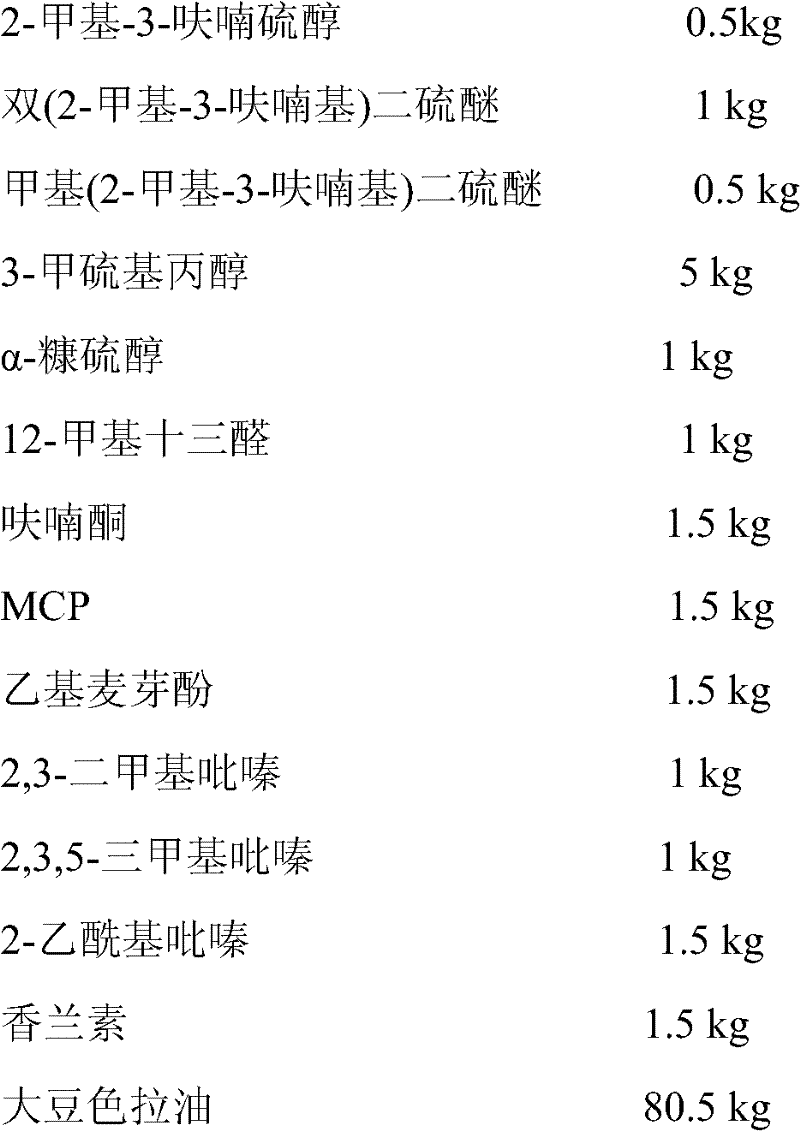

[0018] The formula for producing 100kg beef oily essence is:

[0019]

[0020]

[0021] The production process is as follows: heat 80.5kg of soybean salad oil to 80°C, add 1.5kg of furanone, 1.5kg of MCP, 1.5kg of ethyl maltol, 1.5kg of vanillin, and 1.5kg of 2-acetylpyrazine, and stir until Dissolve completely, add 1kg of 3-mercapto-2-butanol, 0.5kg of 2-methyl-3-furanthiol, 1kg of bis(2-methyl-3-furyl) disulfide, methyl (2-methyl Base-3-furyl) disulfide 0.5kg, 3-methylthiopropanol 5kg, α-furfuryl mercaptan 1kg, 12-methyl tridecanal 1kg, 2,3-dimethylpyrazine 1kg, 2 , 3,5-trimethylpyrazine 1kg, can be packed after stirring evenly.

Embodiment 3

[0023] The formula for producing 100kg beef oily essence is:

[0024]

[0025]

[0026] The production process is: heat 88.6kg of soybean salad oil to 80°C, add 1kg of furanone, 1kg of MCP, 1kg of ethyl maltol, 1kg of vanillin, 1kg of 2-acetylpyrazine, stir until completely dissolved, add 3 -Mercapto-2-butanol 0.5kg, 2-methyl-3-furanthiol 0.2kg, bis(2-methyl-3-furyl) disulfide 0.5kg, methyl (2-methyl-3 -furyl) disulfide 0.2kg, 3-methylthiopropanol 3kg, α-furfuryl mercaptan 0.5kg, 12-methyl tridecanal 0.5kg, 2,3-dimethylpyrazine 0.5kg, 2 , 0.5kg of 3,5-trimethylpyrazine, stir evenly and pack in cans.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com