Spring band installation fixture

A spring hoop and tooling technology, which is used in emergency protection devices, emergency protection device manufacturing, electrical components, etc., can solve the problems of inconvenient assembly and large shrinkage force of the spring hoop.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

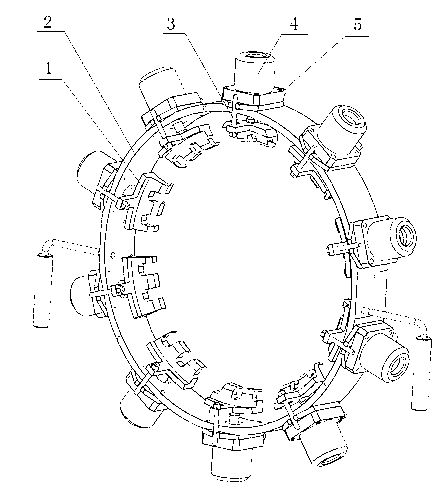

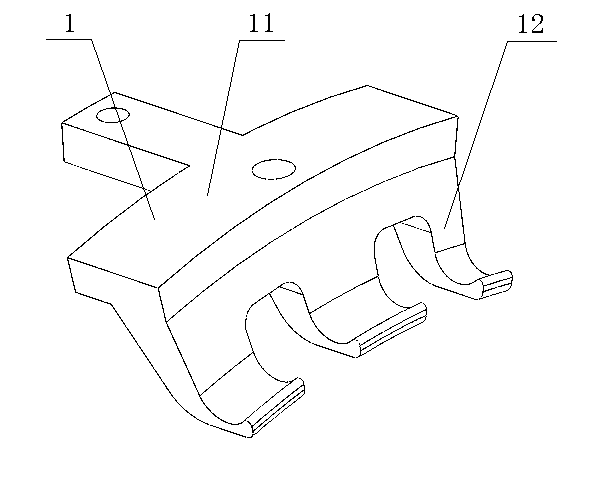

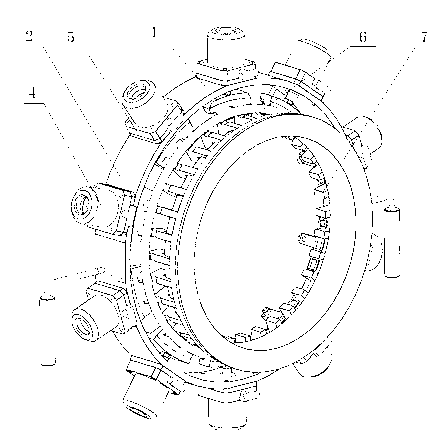

[0014] like Figure 1-3 As shown, a tooling for installing a spring hoop of the present invention includes an annular support 2, and ten cylinders 4 are evenly fixed on the outer wall of the support 2 along the circumferential direction of the support 2, and the cylinder body of the cylinder 4 is connected to the The air source is connected, and the air connection pipe is provided with an air valve (not shown in the figure) to control the on-off of the air connection pipe. The cylinder 4 includes a piston rod that expands and contracts along the radial direction of the bracket 2 and extends to the inner side of the bracket 2. The piston rod passes through the bracket 2, and the end of the piston rod is located inside the bracket 2 and is fixed to hook the inner ring of the spring hoop 6 to apply radial pressure. Claw piece 1 that pulls outward. The claw member 1 is driven by the piston rod of each cylinder 4 to move outward along the radial direction of the bracket 2 .

[00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com