Multi-axial differential absorption spectrometer calibration system and method

A differential absorption and calibration system technology, applied in the measurement of color/spectral characteristics, etc., can solve the problems of calculation result error, lack of standard gas calibration device, unable to detect spectral drift, etc., and achieve the effect of improving the measurement accuracy of the instrument

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

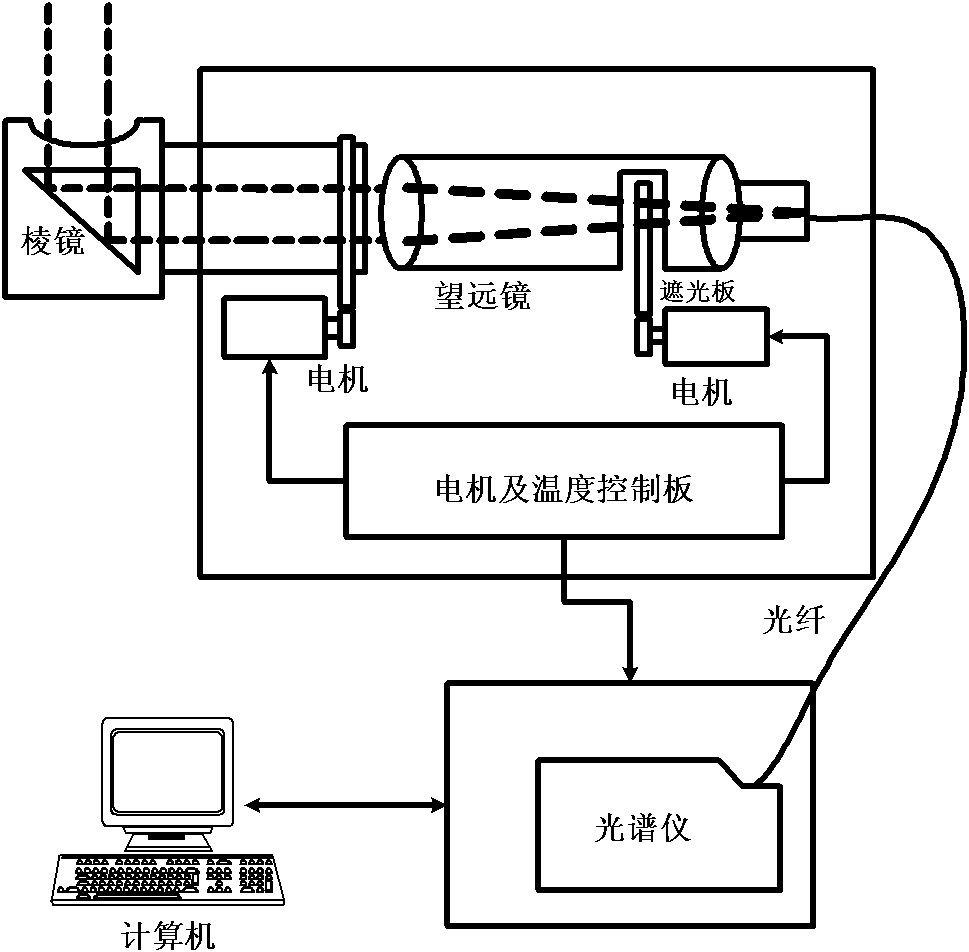

[0019] see figure 2 , multi-axis differential absorption spectrometer calibration system, including a telescope 1, the backscattered light received by the rear end of the telescope 1 is connected to the spectrometer through an optical fiber 2, and the middle part of the lens barrel of the telescope 1 is provided with front and rear holes. The rear two holes are respectively provided with a rotatable standard lamp assembly 3 and a standard gas calibration pool assembly 4. The standard lamp assembly 3 includes a first substrate (a fan-shaped aluminum plate with a certain thickness), and two rectangular holes on the first substrate. A pen-shaped mercury lamp 7 and a halogen tungsten lamp 8 are respectively installed inside; the standard gas calibration cell assembly 4 includes a second substrate (a fan-shaped aluminum plate with a certain thickness), and sulfur dioxide standard gas is respectively installed in two circular holes on the second substrate Absorption cell 9, nitroge...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com