Rotary bottle body water removing machine

A rotary, bottle body technology, used in progressive dryers, dryers, drying solid materials, etc., to ensure stability, reduce the power of the whole machine, and avoid the phenomenon of bottle pouring

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

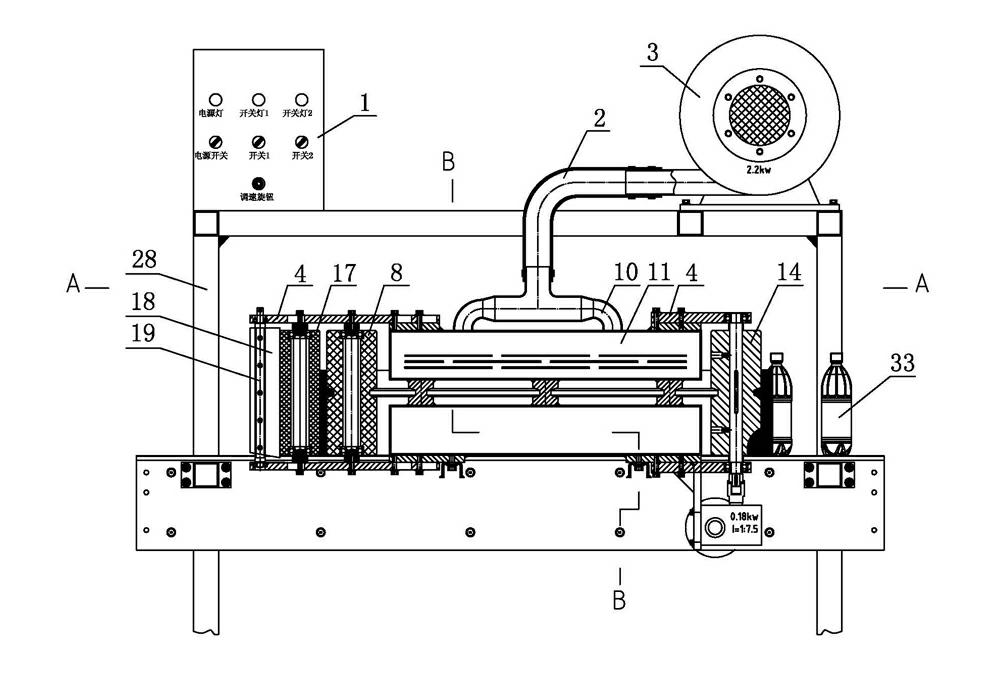

[0029] Such as Figure 3-Figure 5 As shown, the present embodiment includes a frame 28, a conveyor belt 22 installed on the frame for conveying the bottle body 33, and a water tray 30 installed below the conveyor belt, and a control cabinet is installed on the frame 28 1. A water-absorbing pulley mechanism is installed on both sides above the conveyor belt 22 along the direction of movement of the bottle body 33; the gap between the two water-absorbing pulley mechanisms (located directly above the conveyor belt, and its length direction is in line with the movement of the conveyor belt) The same direction) is the water removal channel for passing the bottle. The width of the water removal channel (that is, the distance between the two water suction pulley mechanisms) is smaller than the diameter of the bottle body to ensure that the bottle body can be closely attached to the water suction pulley mechanism contact, so as to realize the function of removing water; the linear spe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com