Oil tube testing plugging process and tube testing plugging device

A plugging and tubing technology, which is applied in the field of well control tools, can solve the problems of not reaching the plugging setting pressure, formation pollution, and increasing construction costs, so as to improve the plugging success rate, ensure the quality of sealing inspection, and improve the construction efficiency. efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

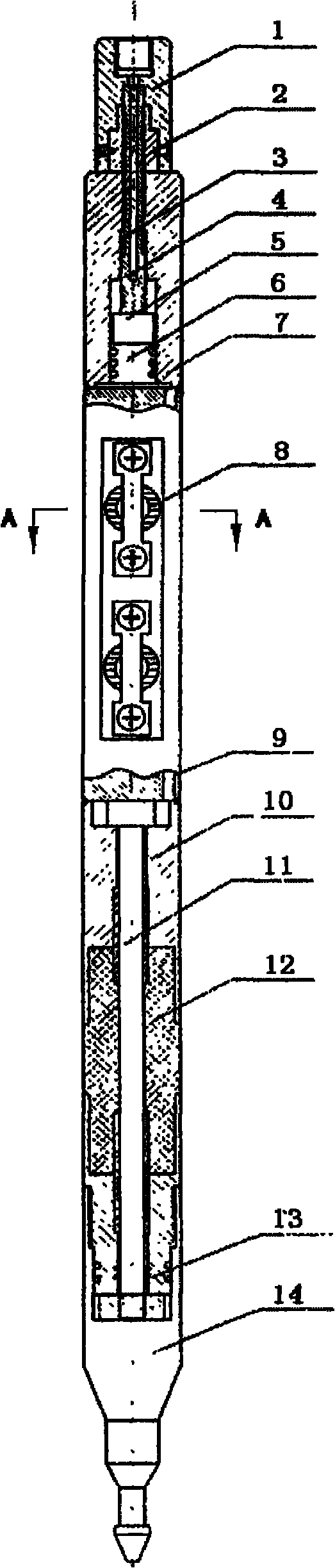

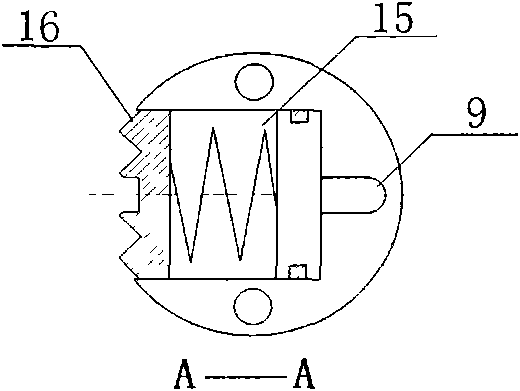

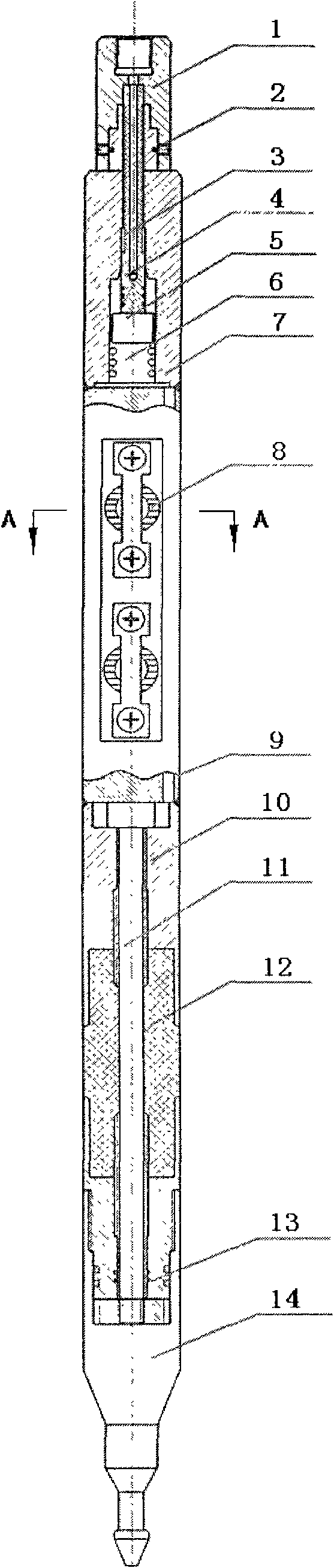

[0015] Below in conjunction with accompanying drawing, the present invention is described in further detail:

[0016] A kind of plugging process of oil pipe test tube is to connect the test tube plug in the oil pipe in the well with the ground pressure test pump through the capillary tube, and use the capillary to connect the internal pressure transmission channel of the test tube plug to verify the leak point of the oil pipe first, and then plug the oil pipe . To verify the leak point of the oil pipe, use the pipe inspection plug to plug the oil pipe without losing hands at different inspection positions, and judge the leak point position of the oil pipe by observing the overflow of the overflow port of the wellhead blowout preventer when the oil pipe is blocked. Plugging the oil pipe is to lower the test tube stopper to the pre-blocking position of the oil pipe, connect the internal pressure transmission channel of the test tube stopper through the capillary, and block the o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com