Bidirectional double-ball standard volume tube

A standard volume, volume tube technology, used in testing/calibration devices, liquid/fluid solids measurement, measurement devices, etc., can solve the problem of difficulty in replacing elastic balls with bidirectional volume tubes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

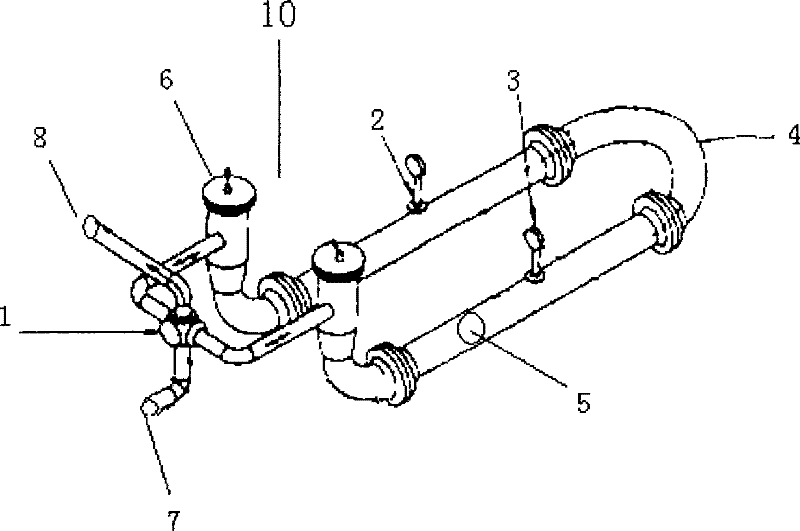

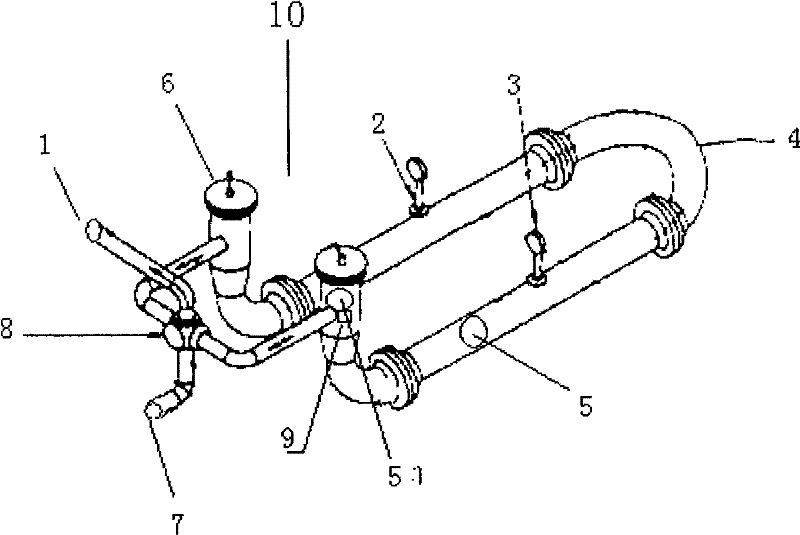

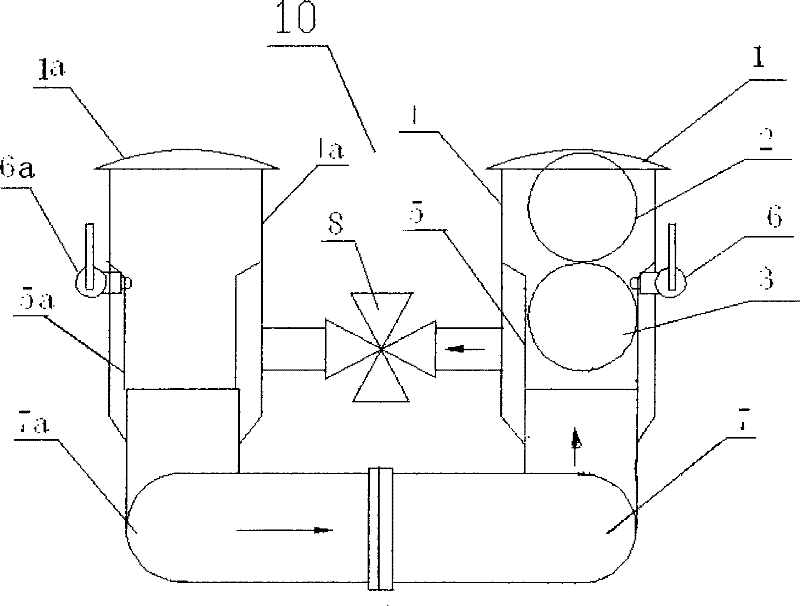

[0016] exist image 3 , Figure 4 , Figure 5 , Figure 6 Middle 10. Volume tube, 1.1a. Quick-opening blind plate, 2. Spare elastic ball, 3. Elastic ball, 4.4a.. Ball storage cavity, 5.5a. Guide rail, 6.6a. Telescopic ejector rod, 7.7a. Standard Pipe section, 8. Four-way valve.

[0017] exist image 3 The medium liquid flows from left to right, pushing the elastic ball (3) to move to the right first in the standard pipe section (7), and then upwards, before the elastic ball (3) leaves the outlet of the standard pipe section (7), the spare elastic ball (2) Push through the telescopic ejector rod (6) and enter the ball storage cavity (4). When the flow rate is small, the elastic ball floats above the outlet of the standard pipe section (7). The distance between the elastic ball and the outlet of the standard pipe section (7) and the size of the flow rate related. The spare elastic ball will be stopped by the quick-opening blind plate (1) and hover on the top of the ball st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com