Intelligent temperature regulating polyurethane energy-saving plate and manufacturing method thereof

A technology of intelligent temperature regulation and polyurethane, which is applied in the direction of building materials, can solve problems such as the inability to realize the temperature regulation function, and achieve the effect of obvious energy saving effect, good stability and stable performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

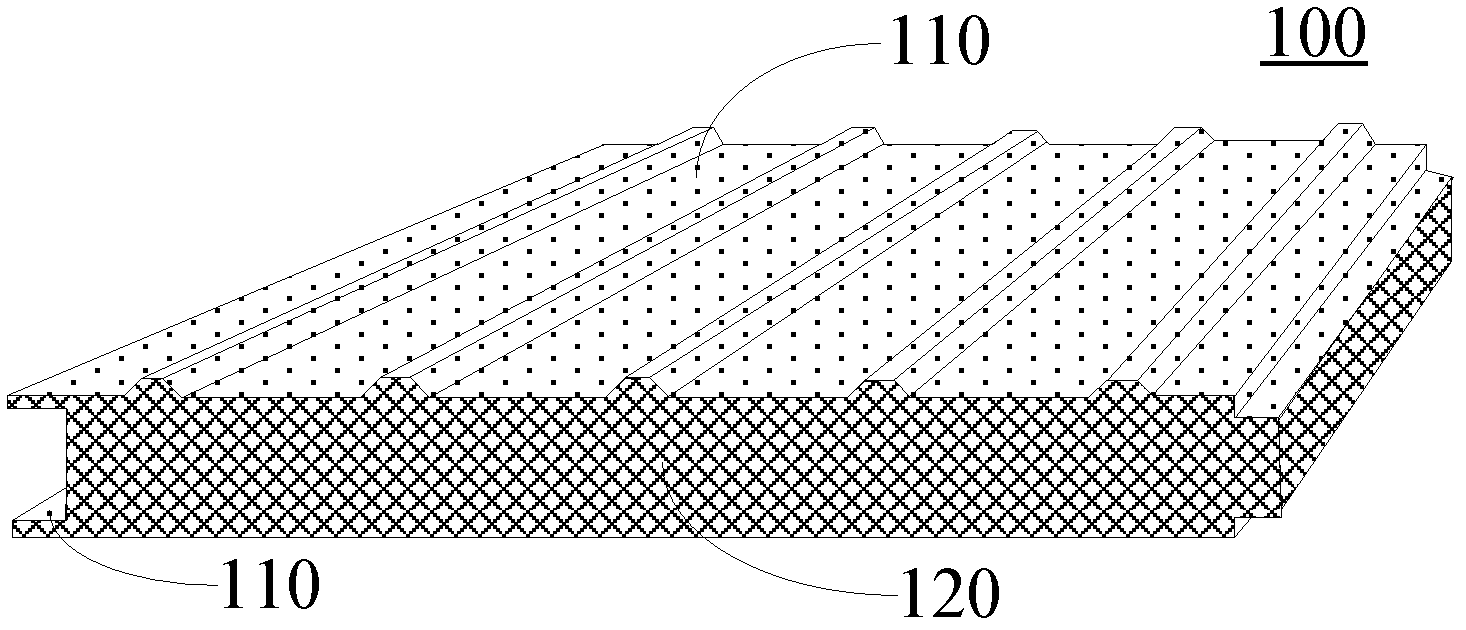

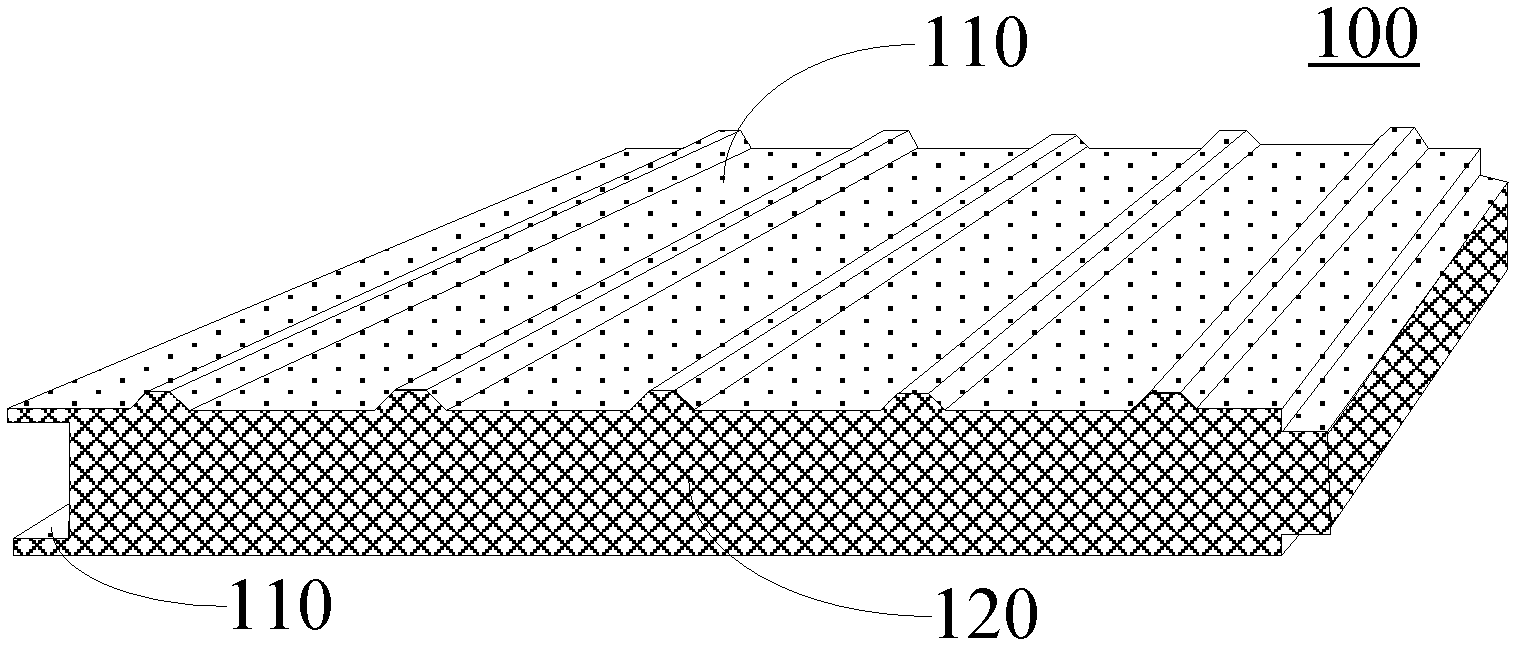

[0026] This embodiment also provides a method for preparing an intelligent temperature-regulating polyurethane energy-saving board, which includes the following steps: adding organic energy storage phase-change materials and nano-processing aids to the combined polyether, adding isocyanate after mixing evenly, and entering the polyurethane continuous Production line, and continuous foaming treatment between two layers of color steel plates to obtain intelligent temperature-regulated polyurethane energy-saving panels. Among them, the weight ratio of isocyanate to combined polyether is 0.8:1-1.2:1, the organic energy storage phase change material accounts for 5%-20% of the weight of the polyurethane composite board, and the nano-processing aid accounts for 0.5%-20% of the weight of the polyurethane composite board. 2%.

[0027] The foaming reaction between the isocyanate and the combined polyether is carried out between the color steel plates 110, the principle of the preparatio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| phase transition temperature | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com