Device for filtering residual ammoniacal liquor and tar by coke

A technology for ammonia water and tar, which is applied in the preparation/separation of ammonia, separation of immiscible liquids, etc., can solve the problems of laborious cylinder production, time-consuming coke removal, poor purification effect, etc., and achieves high equipment utilization and simple and easy production. , the effect of structural science

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

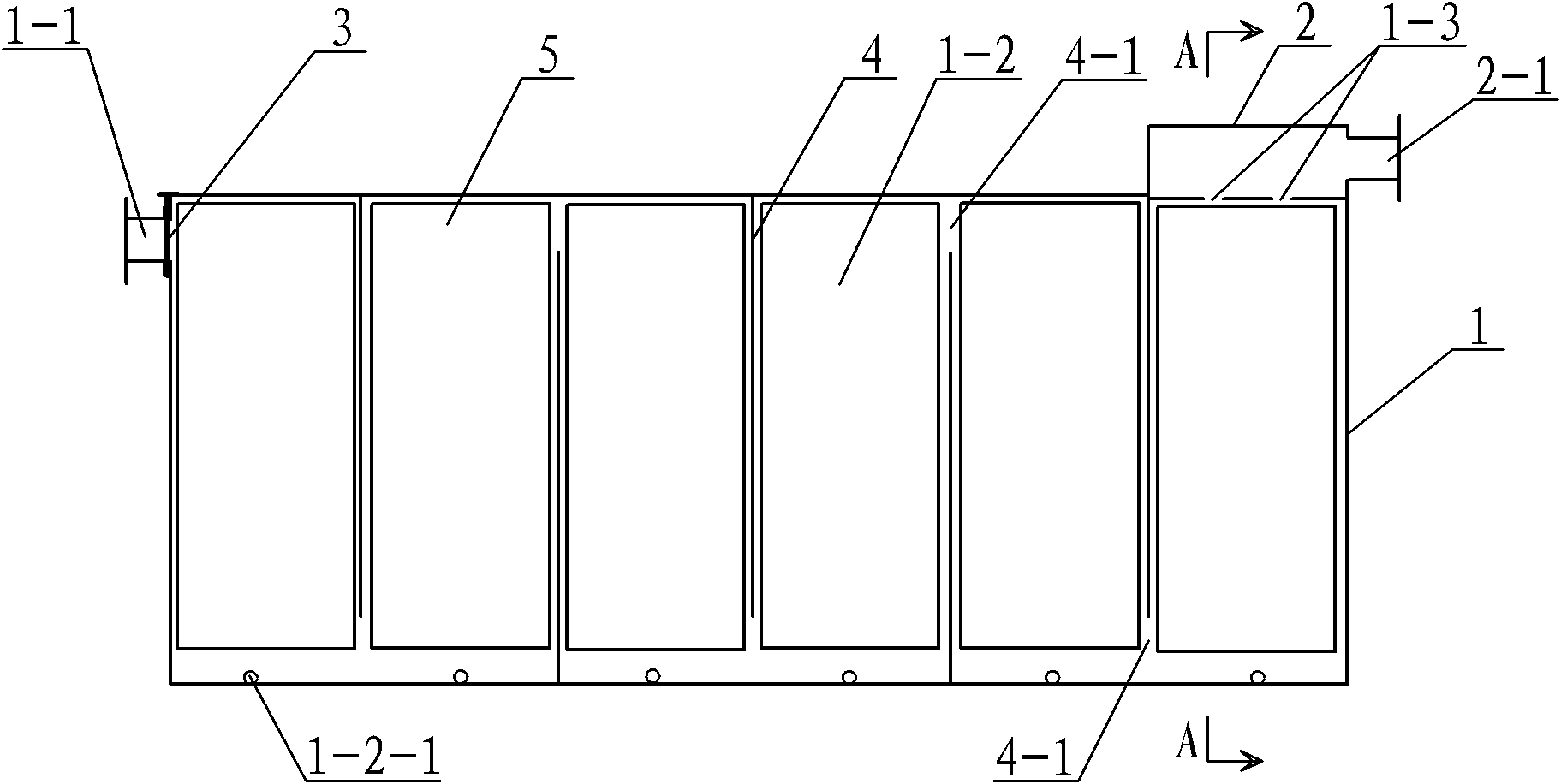

[0007] Specific implementation mode one: combine figure 1 Describe this embodiment, this embodiment comprises box body 1, residual ammonia water distribution groove 2, plug-in filter screen 3, several dividing plates 4 and several iron cages 5, and described box body 1 is cuboid, and described box body 1 One end in the length direction is provided with a remaining ammonia water distribution tank 2, and the remaining ammonia water distribution tank 2 is provided with a tar-containing residual ammonia water inlet 2-1, and the other end of the box body 1 in the length direction is provided with an ammonia water outlet after detarring 1-1, several partitions 4 are arranged sequentially along the length direction of the box body 1, several partitions 4 divide the box body 1 into several filter boxes 1-2, and the remaining ammonia water distribution tank 2 corresponds to the filter box 1-2 Several water holes 1-3 are provided on the side wall of the box body between, and an iron cag...

specific Embodiment approach 2

[0009] Specific implementation mode two: combination figure 1 The present embodiment will be described. The number of filter boxes 1 - 2 in the present embodiment is six. Starting from one end of the remaining ammonia water distribution tank 2, the six filter boxes 1-2 are successively the first filter box, the second filter box, the third filter box, the fourth filter box, the fifth filter box and The sixth filter box, the size of the coke particles in the first filter box and the second filter box is more than 40mm×40mm, and the size of the coke particles in the third filter box and the fourth filter box is 25mm×25mm~40mm ×40mm, the size of the coke particles in the fifth filter box and the sixth filter box is below 10mm×10mm, this design makes the purification effect of residual ammonia water the best. Other components and connections are the same as those in the first embodiment.

specific Embodiment approach 3

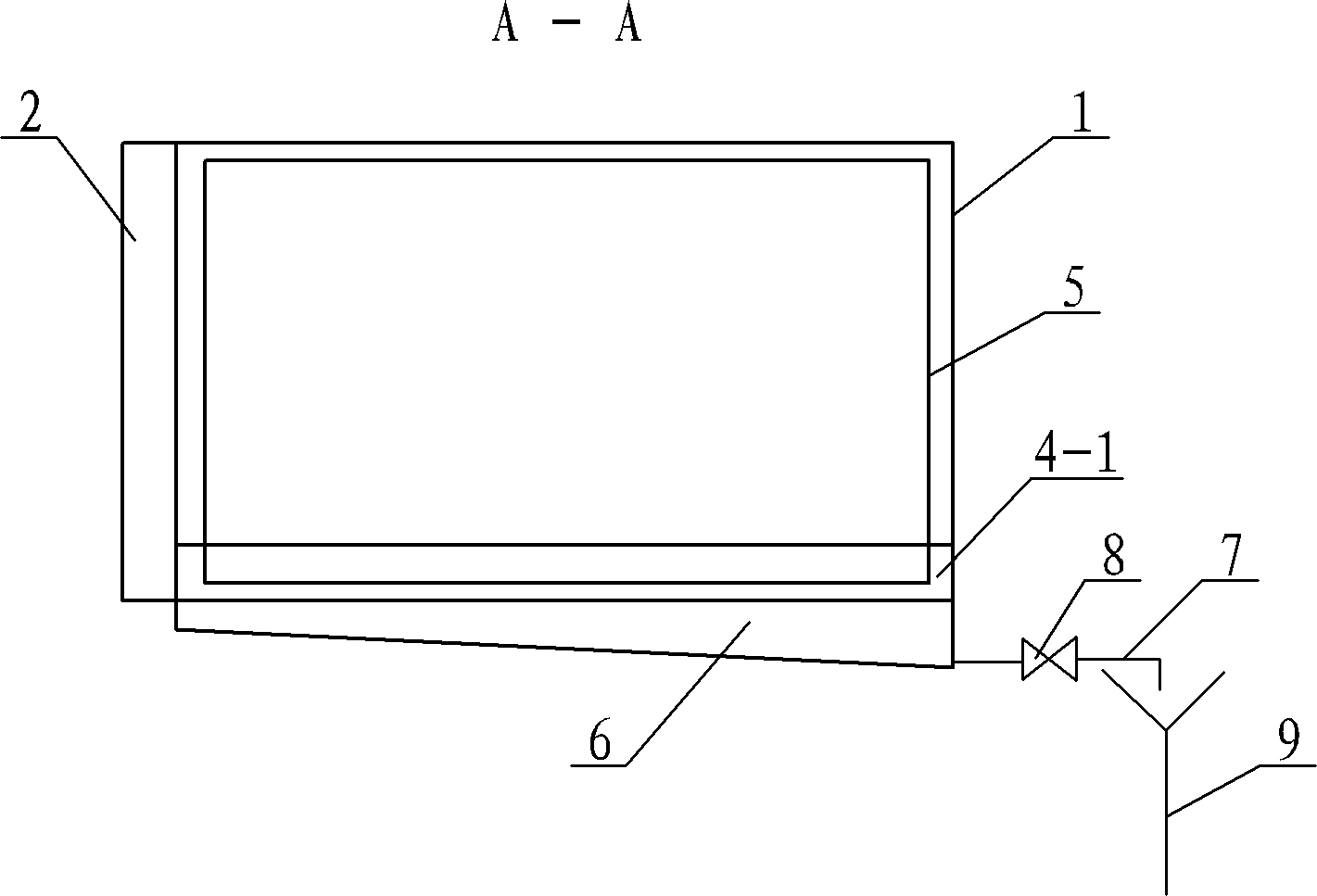

[0010] Specific implementation mode three: combination figure 2 Illustrate this embodiment, what this embodiment is different from specific embodiment one is that it also increases several tar deposition tanks 6, and each filter case 1-2 is provided with a tar deposition tank 6 below, and the bottom end face of tar deposition tank 6 is positioned at One side of the remaining ammonia water distribution tank 2 is arranged inclined downward, and the inclination of the bottom end surface of the tar deposition tank 6 is 1:10˜1:30. This design makes the residual oil or impurities with poor fluidity easy to be discharged from the filter box 1-2 under the action of gravity, thereby ensuring the continuous, stable and efficient operation of the filter box 1-2. Other components and connections are the same as those in the first embodiment.

[0011] Specific implementation mode four: combination figure 2 Describe this embodiment, the difference between this embodiment and specific em...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com