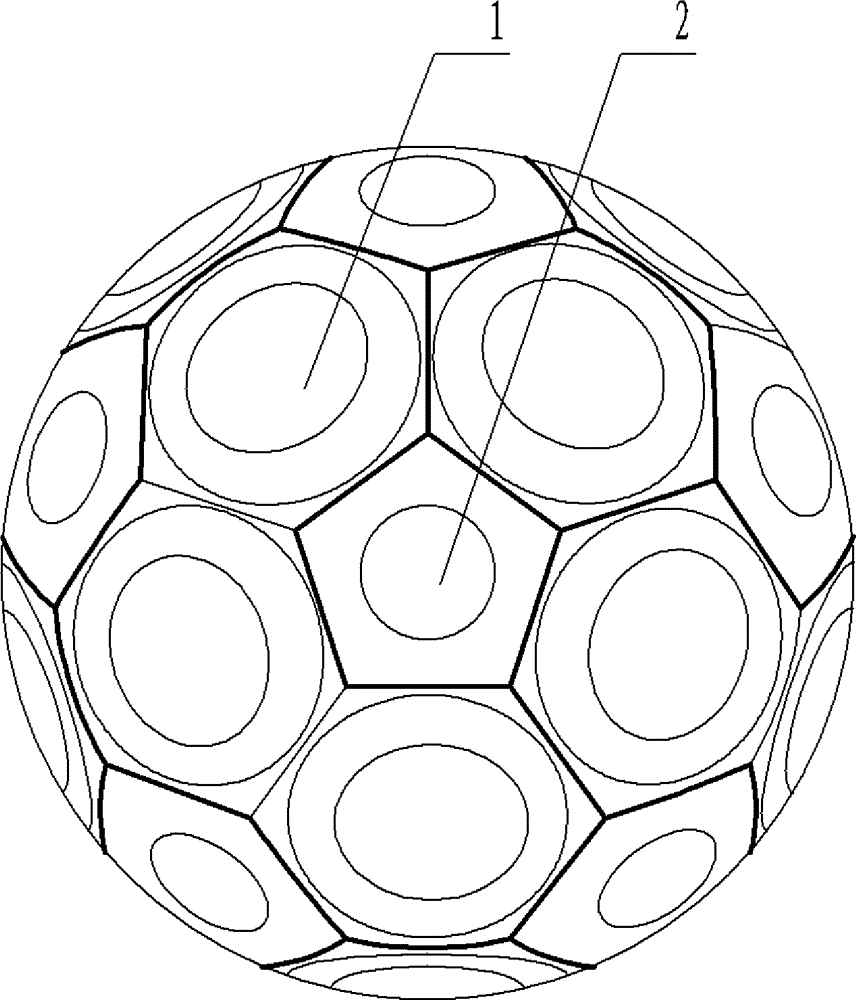

Bamboo ball and production method thereof

A production method and technology of bamboo balls, which are applied in the manufacture of handicraft products and entertainment fields, can solve the problems of good impact resistance and inability to manufacture sizes, etc., and achieve the effects of good impact resistance, small materials, and large sizes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

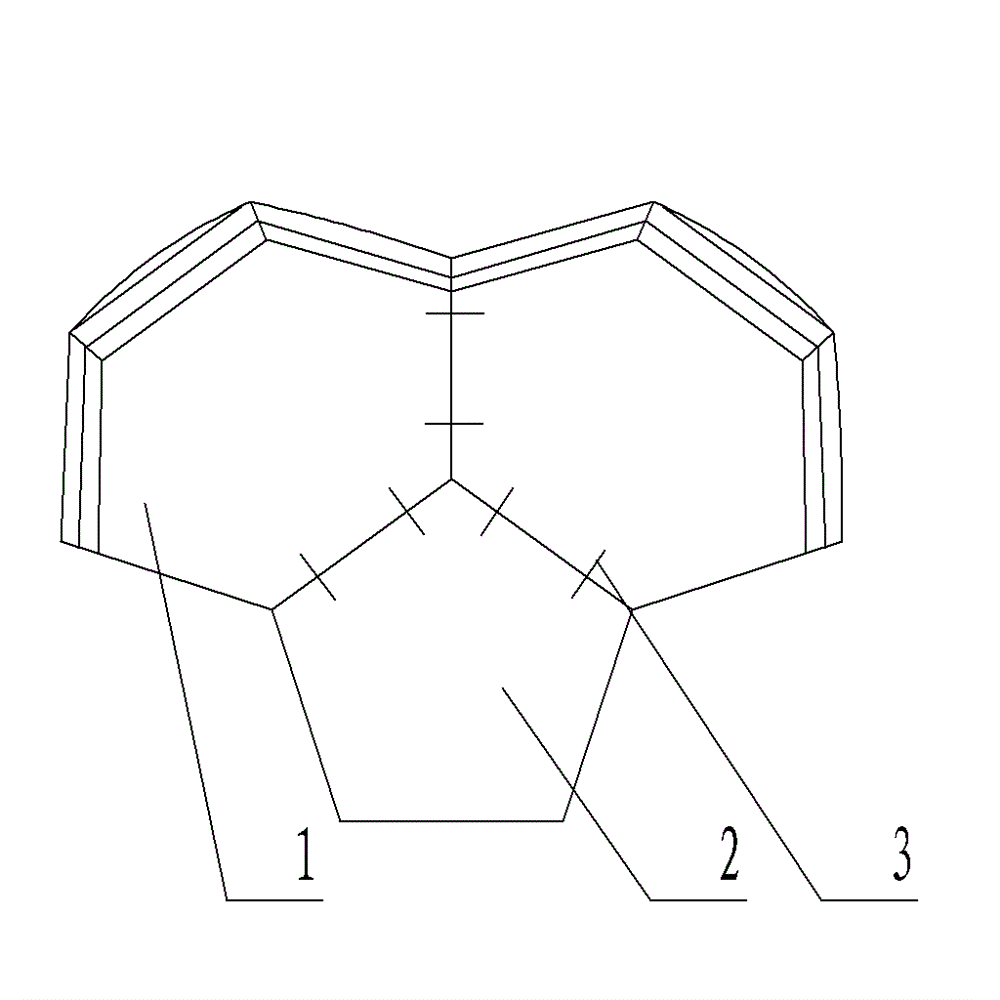

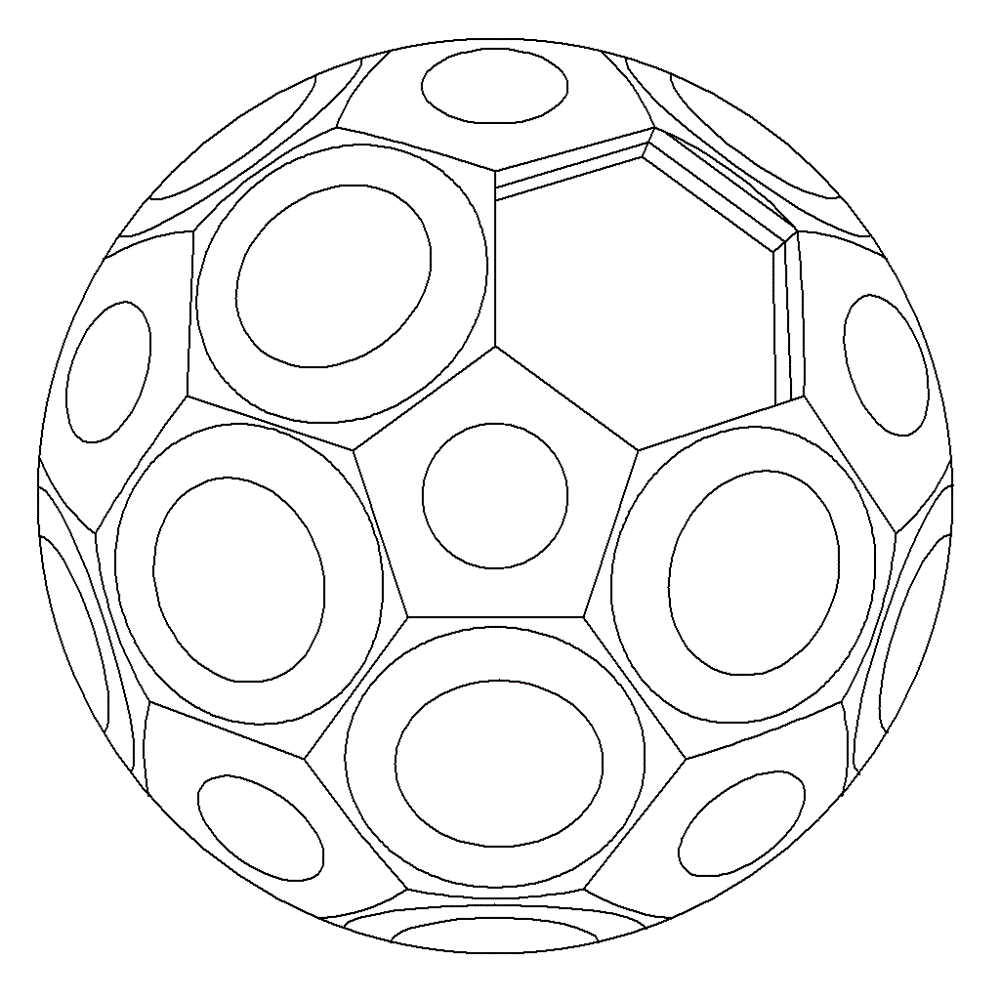

Image

Examples

Embodiment 1

[0026] Embodiment 1——making diameter is the bamboo ball of 220 millimeters football pattern:

[0027] Step 1: Take the bamboo with a growth period of more than three years, saw off the tail, roots and branches and leaves, remove the bamboo green on the outer surface of the bamboo stem, and cut off the bamboo stem according to the length required for the bamboo strip integrated board mold. Become a 1-meter-long bamboo pole;

[0028] The second step: breaking the bamboo pole, removing the bamboo knots and the bamboo yellow part without bamboo fiber on the inner surface, taking the direction of the bamboo fiber as the length direction and breaking it into bamboo strips with a width of not less than 15 mm;

[0029] Step 3: Put the bamboo blanks in a carbonization kettle and heat them with steam to desugar, deacidify, degrease and carbonize them. The heating temperature is 110°C to 130°C for 2 hours;

[0030] The 4th step: the bamboo base bar after heating treatment is carried out...

Embodiment 2

[0036] Embodiment 2——making diameter is the bamboo ball of 200 millimeters football patterns:

[0037] The first step: take the bamboo with a growth period of more than five years, saw off the tail, roots and branches and leaves, remove the bamboo green on the outer surface of the bamboo stem, and cut off the bamboo stem according to the length required for the bamboo strip integrated board mold. Become a 1-meter-long bamboo pole;

[0038] The second step: breaking the bamboo pole, removing the bamboo knots and the bamboo yellow part without bamboo fiber on the inner surface, taking the direction of the bamboo fiber as the length direction, and breaking it into bamboo blank strips with a width of not less than 20 mm;

[0039] Step 3: Put the bamboo blanks in a carbonization kettle and heat them with steam to desugar, deacidify, degrease and carbonize them. The heating temperature is 110°C to 130°C for 3 hours;

[0040]The 4th step: the bamboo base bar after heating treatment ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com