Processing method of bar-shaped fermented tea and composition thereof

A processing method and technology of fermented tea, which is applied in the field of fermented tea, can solve the problems of bitter taste, poor taste, poor finished tea products, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

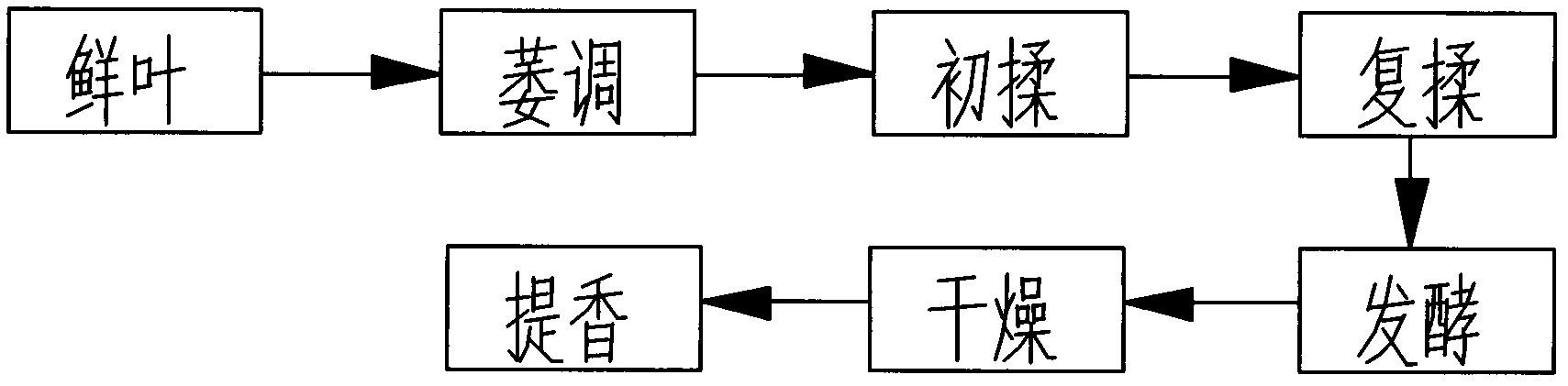

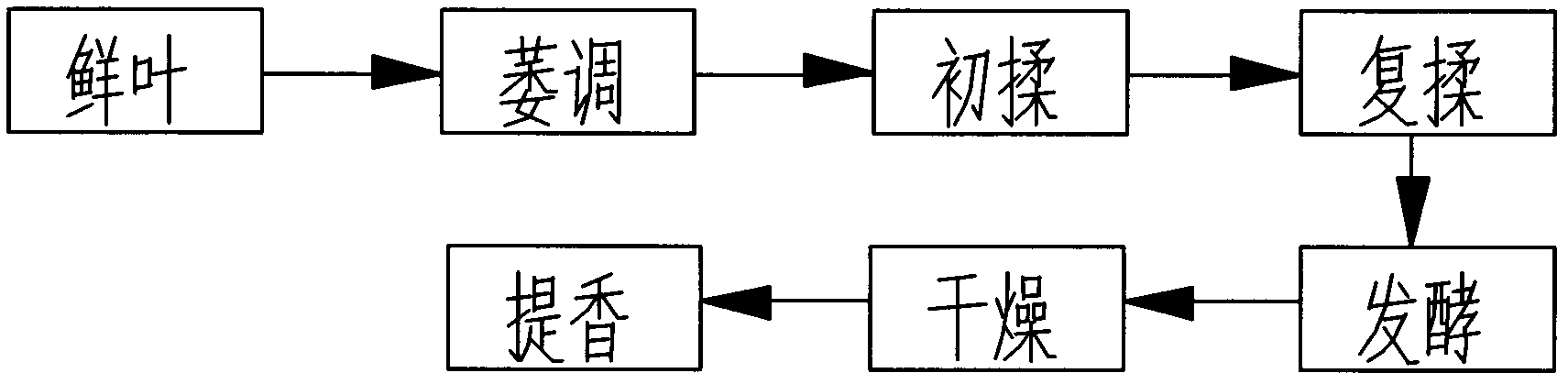

Method used

Image

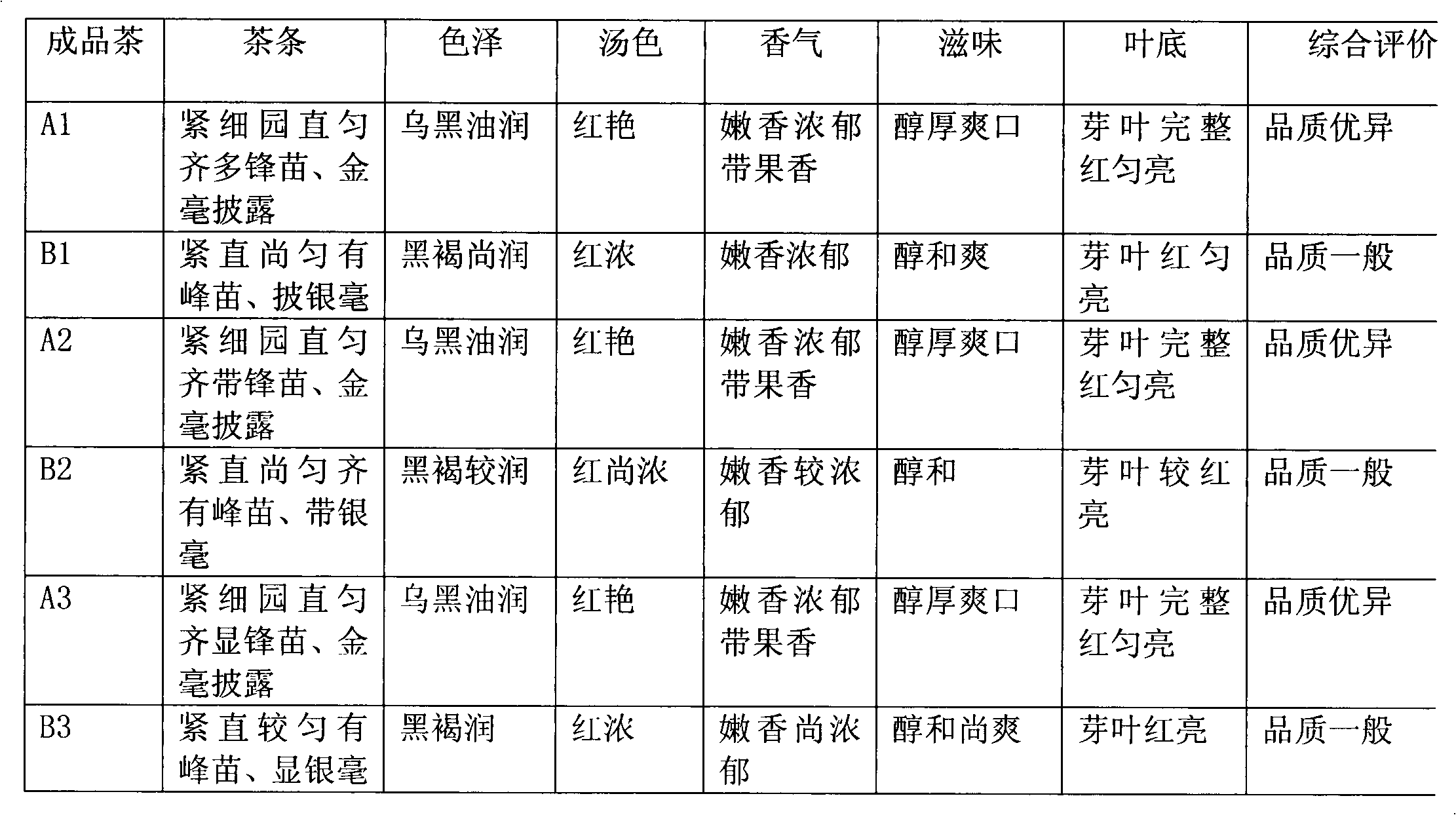

Examples

Embodiment 1

[0051] 1. Fresh leaves:

[0052] The fresh leaves were collected from Fuding Dabaicha tea tree on March 11, the quantity is 169 kg, and the standard of fresh leaves is single bud.

[0053] 2. Withering:

[0054] In the withering workshop, the method of temperature regulation and humidity regulation is adopted for withering. The withering temperature is controlled at 26°C, the withering time is 11 hours, and the aroma of black tea is improved by withering for a long time at low temperature. Air-conditioning equipment is installed in the withering room, and the withering frame is placed indoors, and the withered leaves are thinly spread in the bamboo sieve, and the bamboo sieve spreads 4.5 kilograms of leaves per square meter. Layers are placed on the withering rack, the indoor relative humidity is controlled at 85%, good ventilation is maintained, and the leaves are turned every 3.5 hours.

[0055] The sensory judgment criteria for withered leaves are: the leaves are soft, f...

Embodiment 2

[0074] 1. Fresh leaves:

[0075] The fresh leaves were collected from the famous 131 tea tree on March 15th, the quantity is 213 kg, and the standard of fresh leaves is single bud.

[0076] 2. Withering:

[0077] In the withering workshop, the method of temperature regulation and humidity regulation is adopted for withering. The withering temperature is controlled at 24°C, and the withering time is 10 hours, and the aroma of black tea is improved by withering for a long time at low temperature. Air-conditioning equipment is installed in the withering room, and withering racks are placed indoors, and the withered leaves are thinly spread in the bamboo sieve, and the bamboo sieve spreads 3.5 kilograms of leaves per square meter. Layers are placed on the withering rack, the indoor relative humidity is controlled at 78%, good ventilation is maintained, and the leaves are turned every 2.8 hours.

[0078] The sensory judgment criteria for withered leaves are: the leaves are soft,...

Embodiment 3

[0097] 1. Fresh leaves:

[0098] The fresh leaves were collected from the famous 213 tea tree on March 25, the quantity is 198 kg, and the standard of fresh leaves is single bud.

[0099] 2. Withering:

[0100] In the withering workshop, the method of temperature regulation and humidity regulation is adopted for withering. The withering temperature is controlled at 23°C, the withering time is 9 hours, and the aroma of black tea is improved by withering for a long time at low temperature. Air-conditioning equipment is installed in the withering room, and withering racks are placed indoors, and the withered leaves are thinly spread in the bamboo sieve, and the bamboo sieve spreads 3.5 kilograms of leaves per square meter. Layers are placed on the withering rack, the indoor relative humidity is controlled at 72%, good ventilation is maintained, and the leaves are turned every 2.9 hours.

[0101] The sensory judgment criteria for withered leaves are: the leaves are soft, folded...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com