Process for manufacturing shielding soft cable with two-core semicircular conductor for communication power supply

A semi-circular technology for communication power supply, which is applied in the direction of cable/conductor manufacturing, power cables with shielding layer/conductive layer, circuits, etc., which can solve the problems of increased cable manufacturing costs, large space occupied by cables, and large outer diameter of cables, etc. problem, to achieve the effect of low manufacturing cost, good roundness, advanced technology and practicality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention will be further described below in conjunction with embodiment.

[0012] Take cable RVVZP 0.6 / 1kV 2*240 as an example:

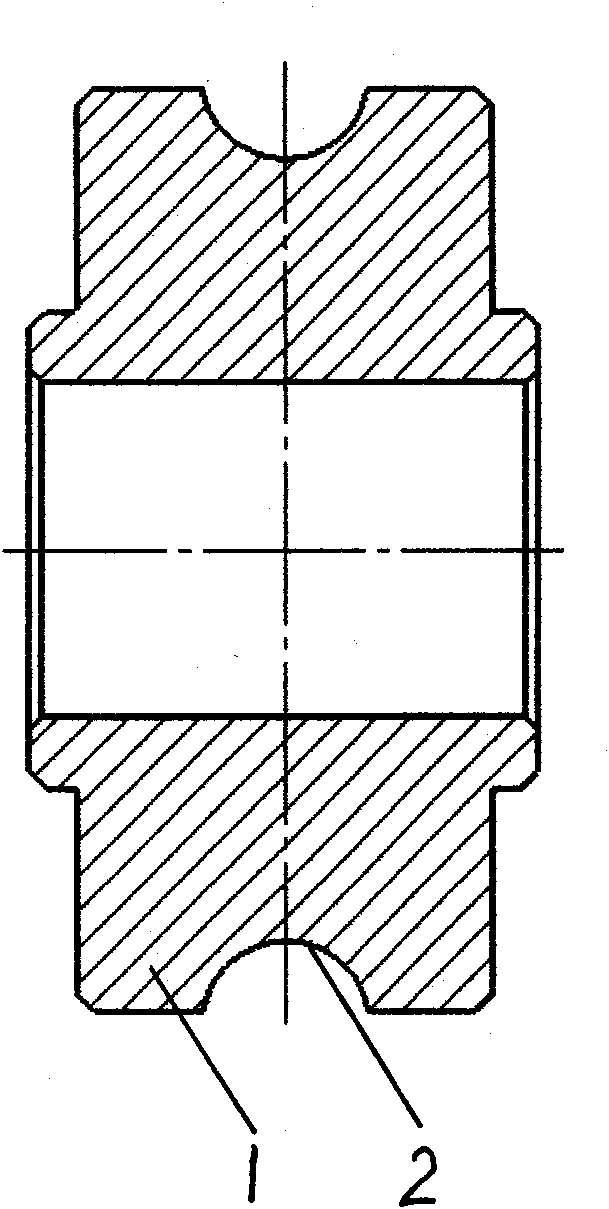

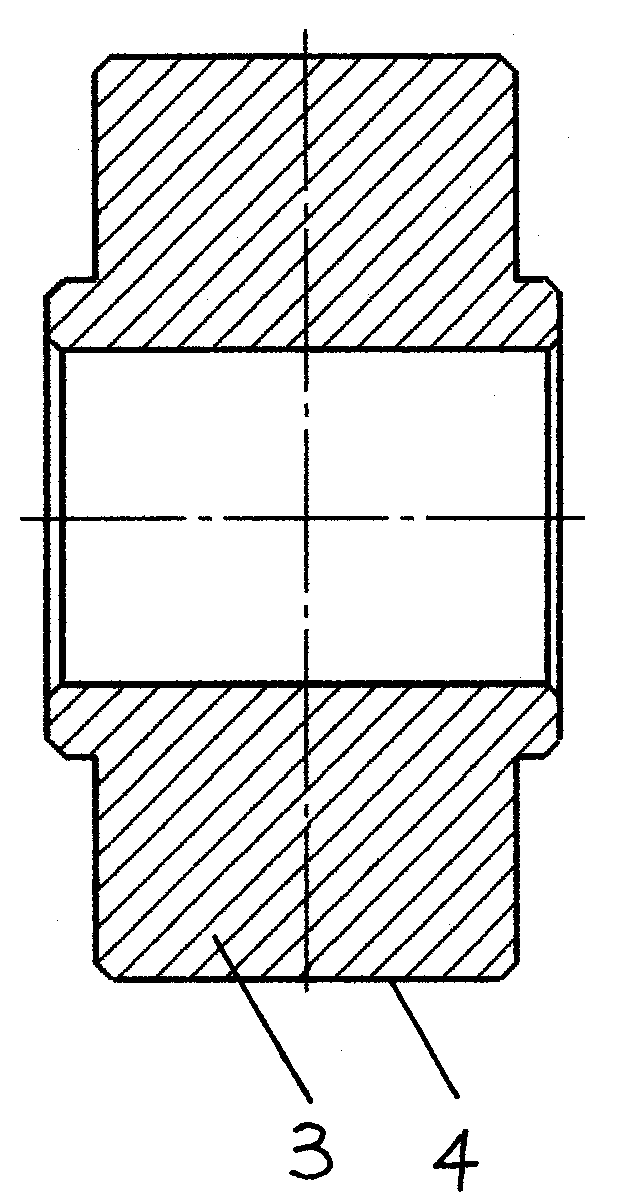

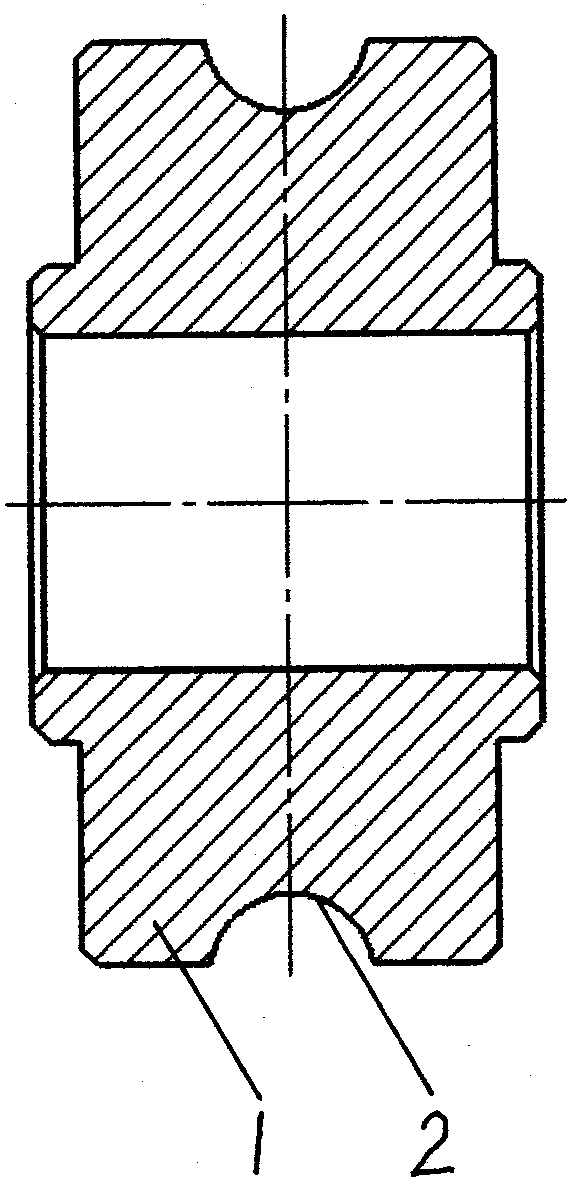

[0013] Strands are composed of 30 monofilaments with a wire diameter of 0.45mm, and 48 coils of strands (30 / 0.45mm) are twisted by a 61-frame stranding machine. The stranding method is 3+9+15+21: 3 coils of strands on the first frame, the stranding direction is left, and the stranding mold is a circular nylon mold; 9 coils of strands are placed on the second frame, and the stranding direction is To the right, the stranding die is a semicircular pinch die composed of upper and lower pinch rollers; the circumference of the upper pinch wheel 1 is provided with a semicircular groove 2, which is a semicircular pinch wheel, and the lower pinch wheel 3 has a The periphery of the circle is plane 4, which is a plane-shaped pressure wheel; 15 coils of strands on the third frame, the twisting direction is right, and the stranding mold is a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com