Tracking type coal bunker material level measurement device

A material level measurement and tracking technology, used in measurement devices, lubrication indicating devices, liquid/fluid solid measurement, etc. Achieve the effect of reducing mechanical operation time, prolonging service life and short operation time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

[0021] 1. Material level measuring device

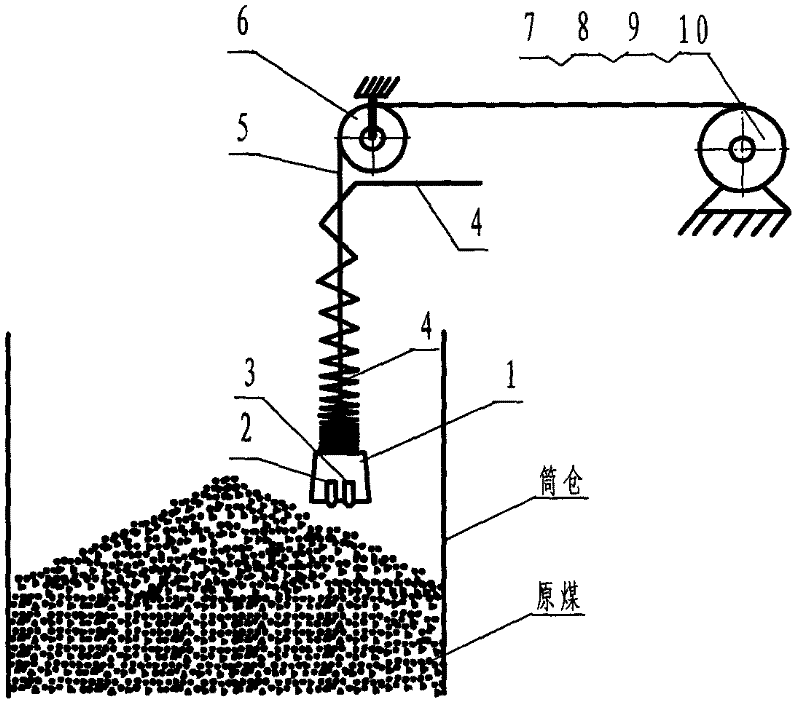

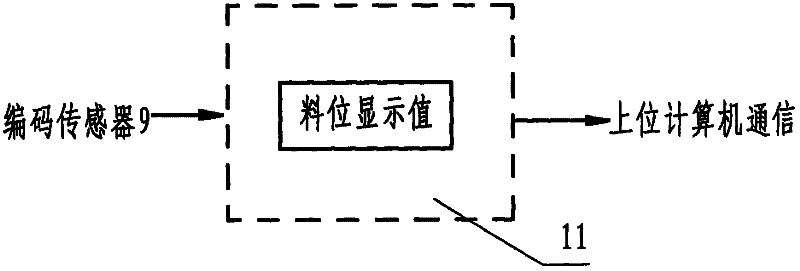

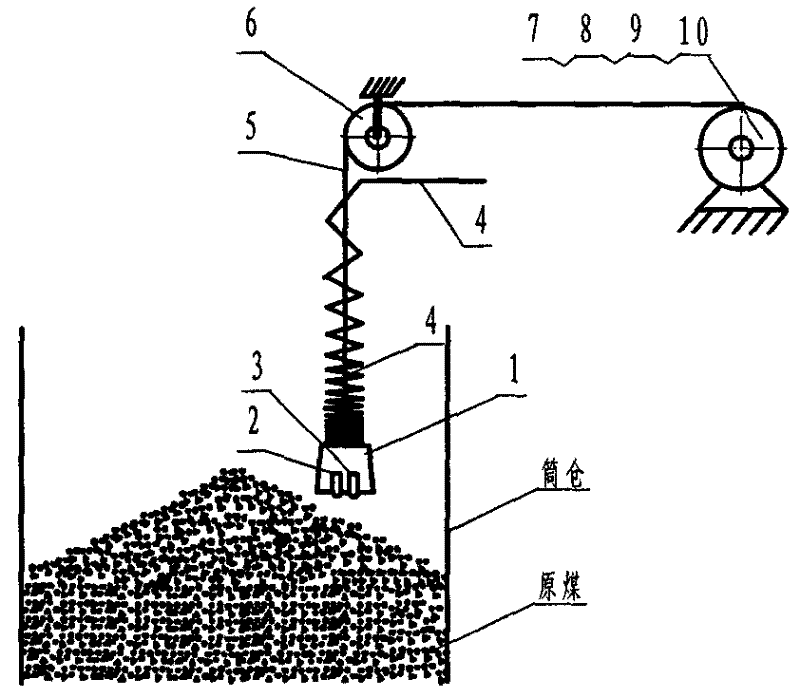

[0022] The material level measuring device of the present invention consists of a probe 1, a transmission system (see attached figure 1 ) And three parts of the measurement system (see attached figure 2 ). Probe 1 is a hollow metal cone with upper limit sensor 2 and lower limit sensor 3 inside. Cable 4 is a wire connecting upper limit sensor 2 and lower limit sensor 3, and the entire hollow metal cone of probe 1 is sealed with epoxy resin; The upper limit sensor 2 and the lower limit sensor 3 are reflective infrared proximity photoelectric switches. When the detected object approaches the upper and lower limit sensors, the infrared light emitted by the infrared sensor transmitters of the upper and lower limit sensors is reflected back to the infrared receiver by the object, and the output switch signals of the upper limit sensor 2 and the lower limit sensor 3 are transmitted to the material level smart meter via the cable 4 11; The t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com