Formula design and adjustment method of lunar regolith simulant for engineering

An adjustment method and technology of lunar soil, which is applied in the field of formulation design and adjustment of engineering simulated lunar soil, can solve the problems of lack of unity, difficulty in large-scale production and purchase, and achieve stable quality, low cost, and simple process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] This example is used in the patrol field, the quantity is 400m 3 , the performance requirements are shown in Table 2. This example includes the following steps:

[0043] (1) Selection of raw materials:

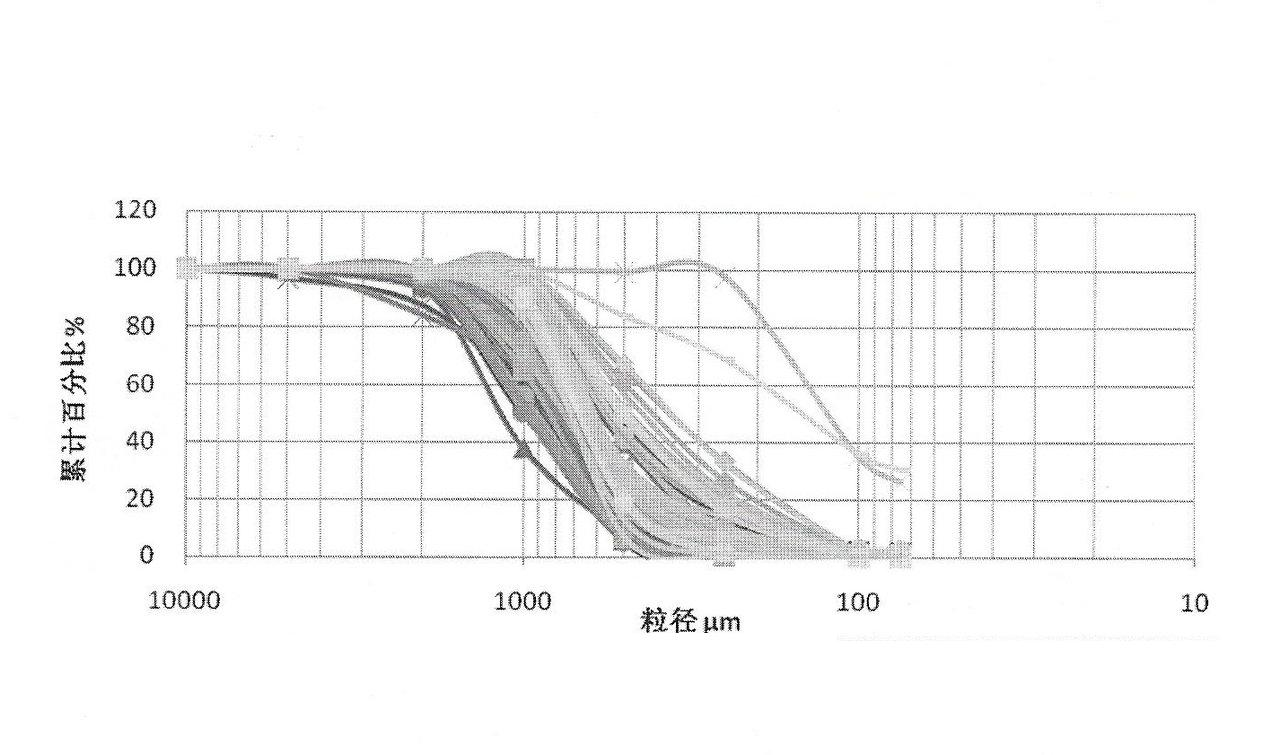

[0044] The black-gray volcanic slag of Gushan Mountain in Jinchuan Town, Huinan County was selected as the raw material for the preparation of simulated lunar soil. According to the distribution law of lunar soil particle size and the statistical results of the median particle size, the principle design of particle size ratio is carried out for the needs of the internal field. Within the particle size distribution of lunar soil, the expected physical and mechanical properties are close to the real lunar soil, as shown in Table 2.

[0045] Table 2

[0046]

[0047] *Values suggested by NASA.

[0048] (2) Formula design:

[0049] The preparation process of simulated lunar soil for engineering is mainly drying-pulverizing-pulverizing-sorting-proportioning, that i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com