Sensitivity calibration method of fiber Bragg grating strain sensor

A strain sensor and fiber grating technology, applied in the field of measurement, can solve problems such as affecting the measurement results and low accuracy, and achieve the effects of uniform loading, uniform force and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be described in further detail below by means of specific embodiments:

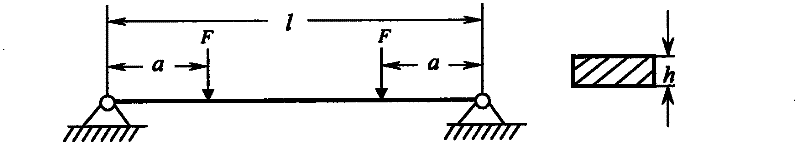

[0026] The method for calibrating the sensitivity of the optical fiber grating strain sensor of the present invention utilizes four-point bend equal-intensity beams to calibrate the sensitivity of the optical fiber grating strain sensor.

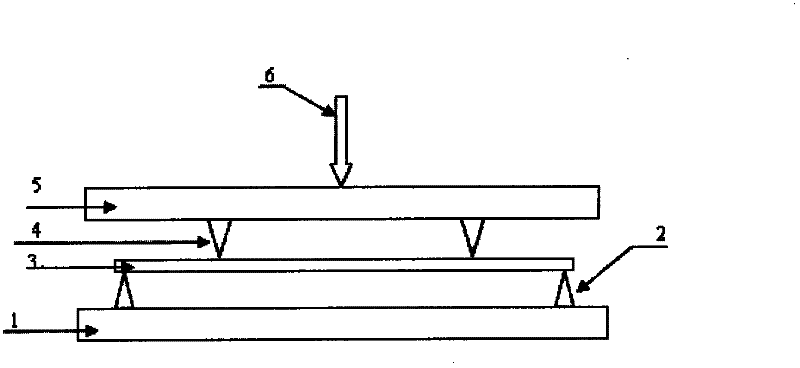

[0027] See figure 1 , which is the loading calibration system of the fiber grating strain sensor sensitivity calibration method of the present invention, including a fixed platform 1, a standard beam fulcrum 2, a standard beam 3, a fiber grating working section, a loading point 4, a loading beam 5, and a top loading 6. Wherein, the fixed platform 1 is a fixed part, and the area of the fixed platform is relatively large, in order to bring convenience to the measurement. The standard beam is set on the fixed platform 1 through the standard beam fulcrum 2, and the size and material of the standard beam can be changed as required. At th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com