Inner expansion connecting structure for screw sleeve type steel and plastic composite pipe

A technology of steel-plastic composite pipe and connection structure, which is applied in the direction of sealing surface connection, pipe/pipe joint/pipe fitting, passing components, etc., which can solve problems such as easy leakage, small deformation, and bad influence of pipe connection sealing, and achieve airtightness Reliable and effective in improving pull-out resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

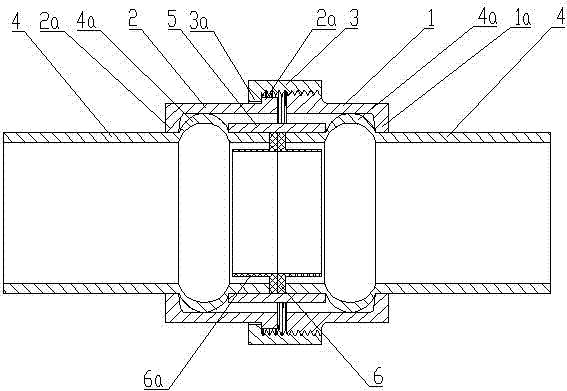

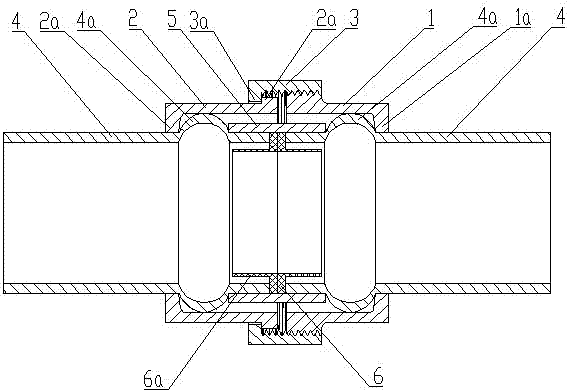

[0013] The present invention will be described in detail below in conjunction with the accompanying drawings, as shown in the figure: the screw sleeve type steel-plastic composite pipe internal expansion connection structure of this embodiment includes a threaded sleeve 1 and a ferrule 2 coaxially arranged side by side, and a threaded sleeve 1 and a ferrule. The sleeve 2 has a screw sleeve 3 that adjusts the distance between the two. An axial support step 2a is arranged on the outer circle of the ferrule 2. The internal thread of the screw sleeve 3 cooperates with the external thread of the threaded sleeve 1. One end is provided with an axial tension step 3a that withstands the axial support step 2a, and the distance between the threaded sleeve 1 and the ferrule 2 can be adjusted by turning the threaded sleeve 3, and the threaded sleeve 1 is far away from the end of the ferrule 2 and the ferrule. The end of the sleeve 2 away from the threaded sleeve 1 is provided with an annula...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com