Injection section combination building template

A construction formwork and injection molding technology, which is applied in the direction of construction, building structure, and on-site preparation of building components, can solve the problems of less repeated use, troublesome loading and unloading, and low use efficiency, and achieve long service life, easy disassembly, The effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

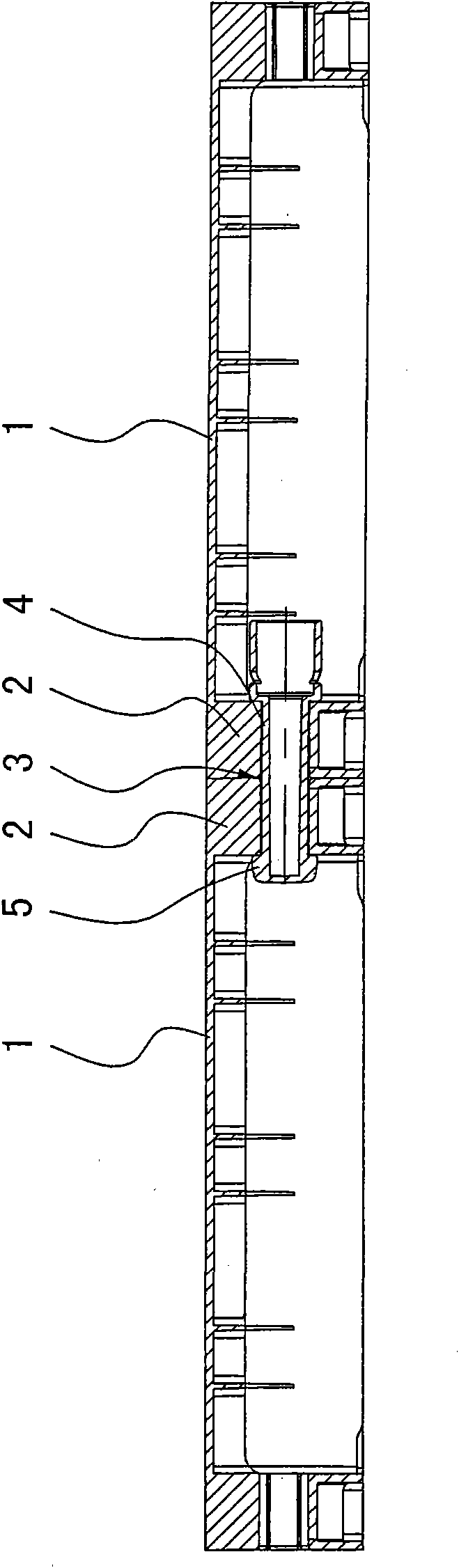

[0012] The present invention relates to a kind of injection molded block combination building formwork, such as Figure 1-Figure 5 As shown, it includes at least two building templates 1 made of plastic materials, and is characterized in that frame 2 is formed around each building template 1, and connecting holes 3 are formed in the frame 2, and each connecting hole 3 is connected by Pin 4 is connected, and the head of connecting pin 4 is shaped on fastening lock head 5. The building template 1 described in the technical solution is made of plastic material, which is light in weight, non-corrosive, long in service life, low in cost, does not bond with concrete, and can be reused many times. In particular, frames 2 are formed around each building formwork 1, and connection holes 3 are formed in the frame 2. Each connection hole 3 is connected by connection pins 4, and the head of connection pins 4 is formed with a fastening lock head 5. When placing each building formwork flat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com