Device for quenching of elongated steel wire

A technology of quenching device and steel wire, applied in the direction of quenching device, furnace, heat treatment equipment, etc., can solve the problems of long experience, loss of heating effect of steel wire, inability to apply metal mesh wire, etc., to achieve accurate quenching temperature and ensure heat treatment effect. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

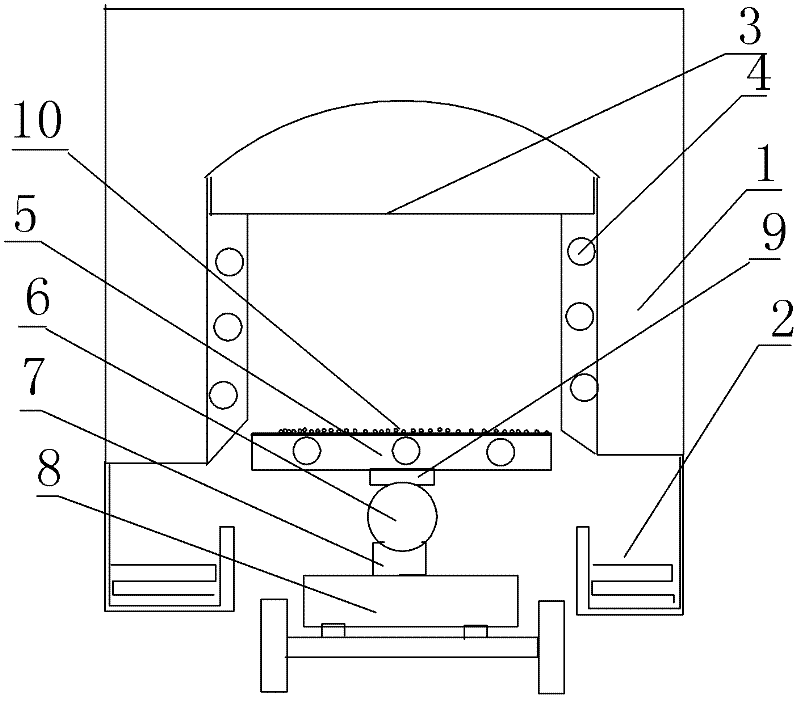

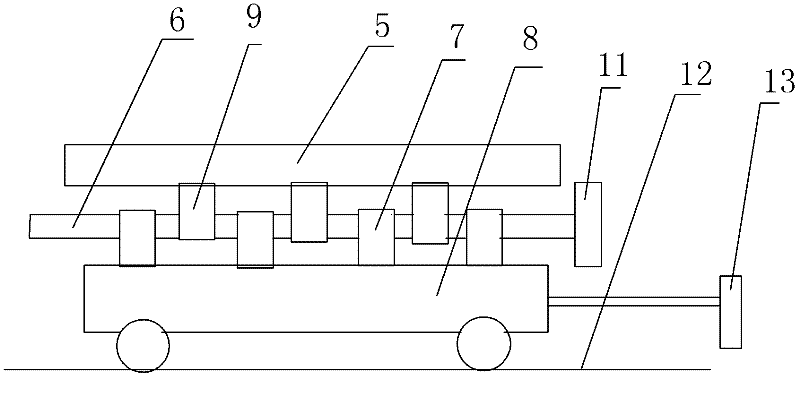

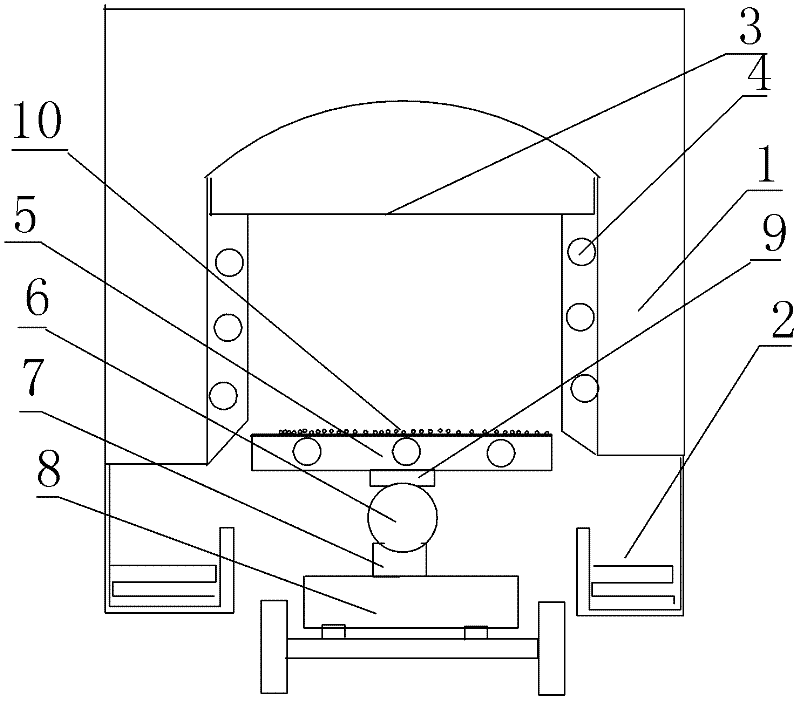

[0018] Such as figure 1 and figure 2 As shown, the device for quenching the slender steel wire in the present invention includes a quenching furnace 1, a heating chamber is arranged in the quenching furnace 1, and at least one cooling oil tank 2 is provided at the bottom of the heating chamber along the length direction of the quenching furnace; it also includes a transport steel wire The transport mechanism that enters the heating chamber, the transport mechanism includes a transport trolley 8 and a carrier plate 5, the carrier plate 5 and the transport trolley 8 are connected by a turning mechanism, the steel wire 10 is placed on the carrier plate 5, and the steel wire 10 is heated to the required temperature in the heating chamber Finally, the carrier plate 5 is turned over by the turning mechanism, and the steel wire is poured into the cooling oil tank 2 directly. The invention is a device for quenching the elongated steel wires used for making metal screens, which integ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com