Combustion gas generator of biomass

A biomass gas and generator technology, which is used in the manufacture of combustible gas, fixed bed gasification, petroleum industry, etc., can solve the problems of limiting the wide application of biomass gasification devices, reducing equipment utilization, and reducing production efficiency. Improve utilization and production efficiency, reduce labor intensity, and avoid waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

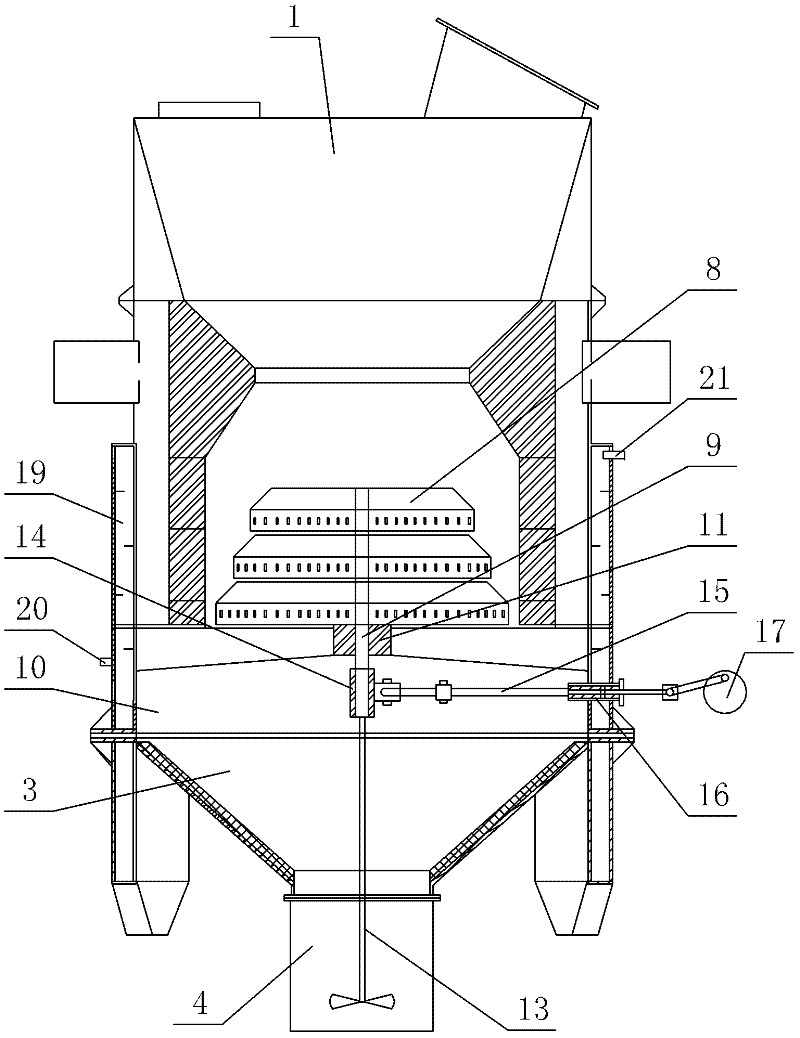

[0020] In order to clearly illustrate the technical features of this solution, the present invention will be described in detail below through specific implementation modes and in conjunction with the accompanying drawings.

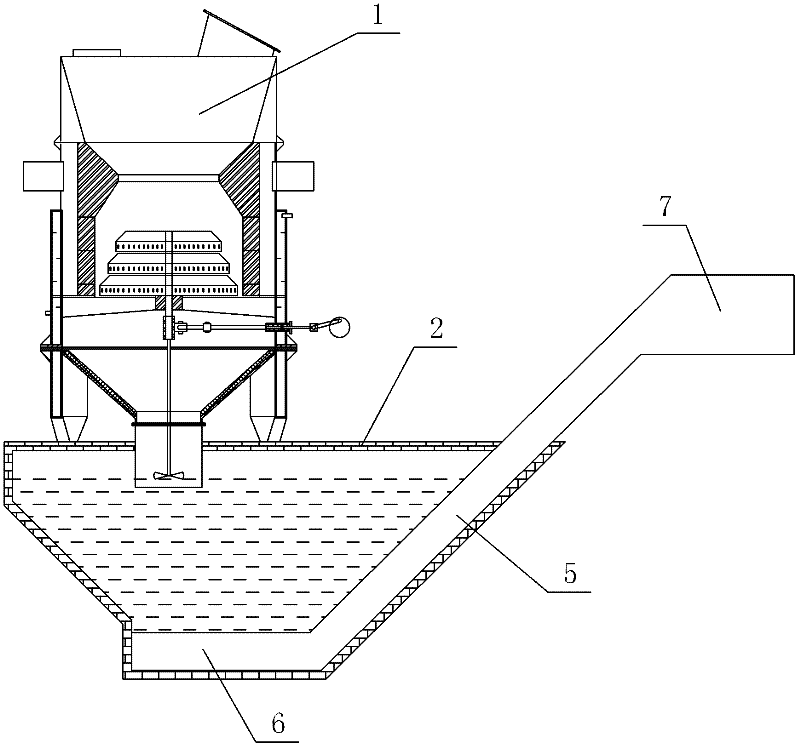

[0021] Such as Figure 1~6 Shown, the present invention comprises gasification furnace 1, is provided with the airtight deashing pool 2 that an inside is filled with water in the bottom of gasification furnace 1, is located at the lower furnace body 3 bottom of gasification furnace 1 and stretches into In the ash removal tank 2, an ash removal device 5 is arranged in the ash removal tank 2. The ash suction end 6 of the ash removal device 5 extends to the bottom of the ash removal tank 2, and the ash output end 7 extends to the outside of the ash removal tank 2.

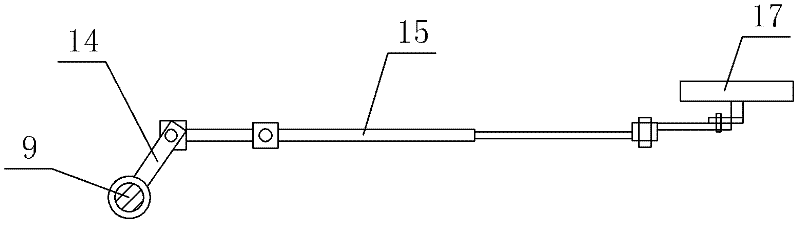

[0022] The grate 8 of the gasification furnace 1 is composed of several layers of sub-grates arranged sequentially from top to bottom, and each sub-grate is fixedly connected with a rotating shaf...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com