Method for producing pneumatic tire and pneumatic tire

A technology for pneumatic tires and green tires, which can be used in pneumatic tires, special tires, tire parts, etc., and can solve problems such as bad appearance and impression

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

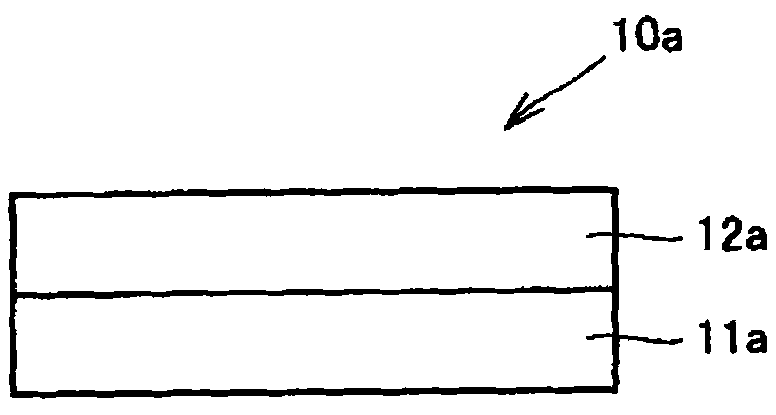

[0063] like figure 2 As shown, in one embodiment of the invention, a polymeric laminate 10a is composed of a first layer 11a and a second A-layer 12a.

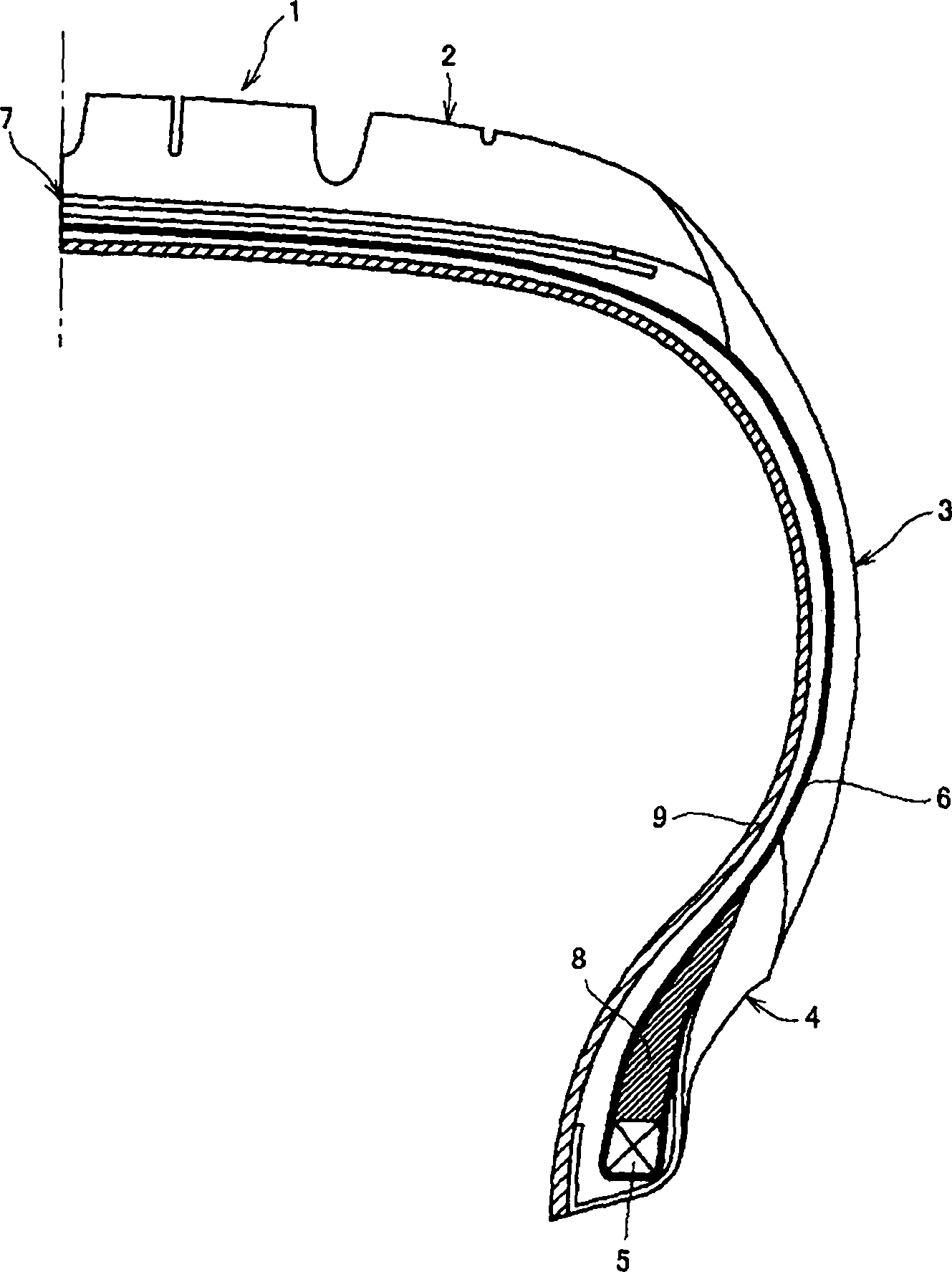

[0064] see figure 1 , when the polymer laminate 10a is used as the airtight layer 9 of the pneumatic tire 1, if the surface where the first layer 11a is located is set toward the radially innermost side of the tire, and the surface where the second A layer 12a is located is set toward the radially outer side In order to reach the carcass 6, the second A layer 12a and the carcass 6 can be vulcanized into bonds in the tire vulcanization step. Therefore, since the inner liner 9 is satisfactorily bonded to the rubber layer of the carcass 6, the resulting pneumatic tire 1 can have excellent air permeability resistance and durability.

specific Embodiment approach 2

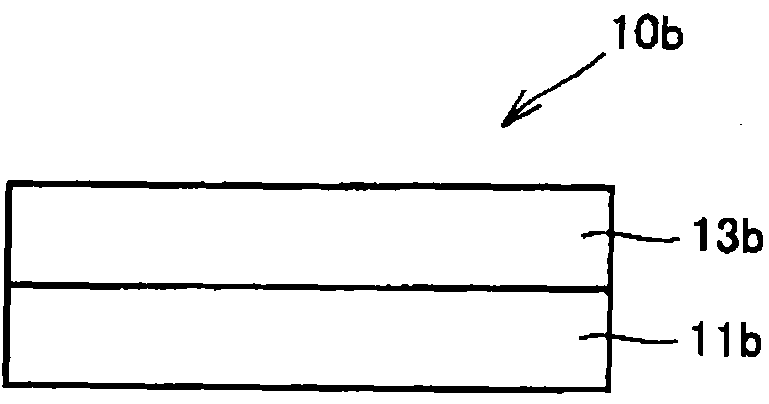

[0065] like image 3 As shown, in one embodiment of the invention, the polymer laminate 10b is composed of a first layer 11b and a second B layer 13b.

[0066] see figure 1 , when the polymer laminate 10b is used as the airtight layer 9 of the pneumatic tire 1, if the surface where the first layer 11a is located is arranged toward the innermost side in the tire radial direction, and the surface where the second B layer 13b is located is arranged toward the radially outer side In order to reach the carcass 6, the second B layer 13b and the carcass 6 can be vulcanized into bonds in the tire vulcanization step. Therefore, since the inner liner 9 is satisfactorily bonded to the rubber layer of the carcass 6, the resulting pneumatic tire 1 can have excellent air permeability resistance and durability.

specific Embodiment approach 3

[0067] like Figure 4 As shown, in one embodiment of the present invention, a polymer laminate 10c is laminated from a first layer 11c, a second A layer 12c, and a second B layer 13c in the order described above.

[0068] see figure 1 , when the polymer laminate 10c is used as the airtight layer 9 of the pneumatic tire 1, if the surface where the first layer 11c is located is set toward the innermost side in the tire radial direction, and the surface where the second B layer 13c is located is set toward the radially outer side In order to reach the carcass 6, the second B layer 13c and the carcass 6 can be vulcanized into bonds in the tire vulcanization step. Therefore, since the inner liner 9 is satisfactorily bonded to the rubber layer of the carcass 6, the resulting pneumatic tire 1 can have excellent air permeability resistance and durability.

PUM

| Property | Measurement | Unit |

|---|---|---|

| degree of polymerization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com