Process and equipment for distributing ceramic micro powder bricks

A technology of porcelain tiles and fabrics, which is applied in the manufacture of tools, supply devices, etc., can solve the problems of monotonous polished tiles, lack of natural stone panels and decorative effects, and stiff lines and textures, achieving rich colors, vivid textures, The effect of matching and coordinating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

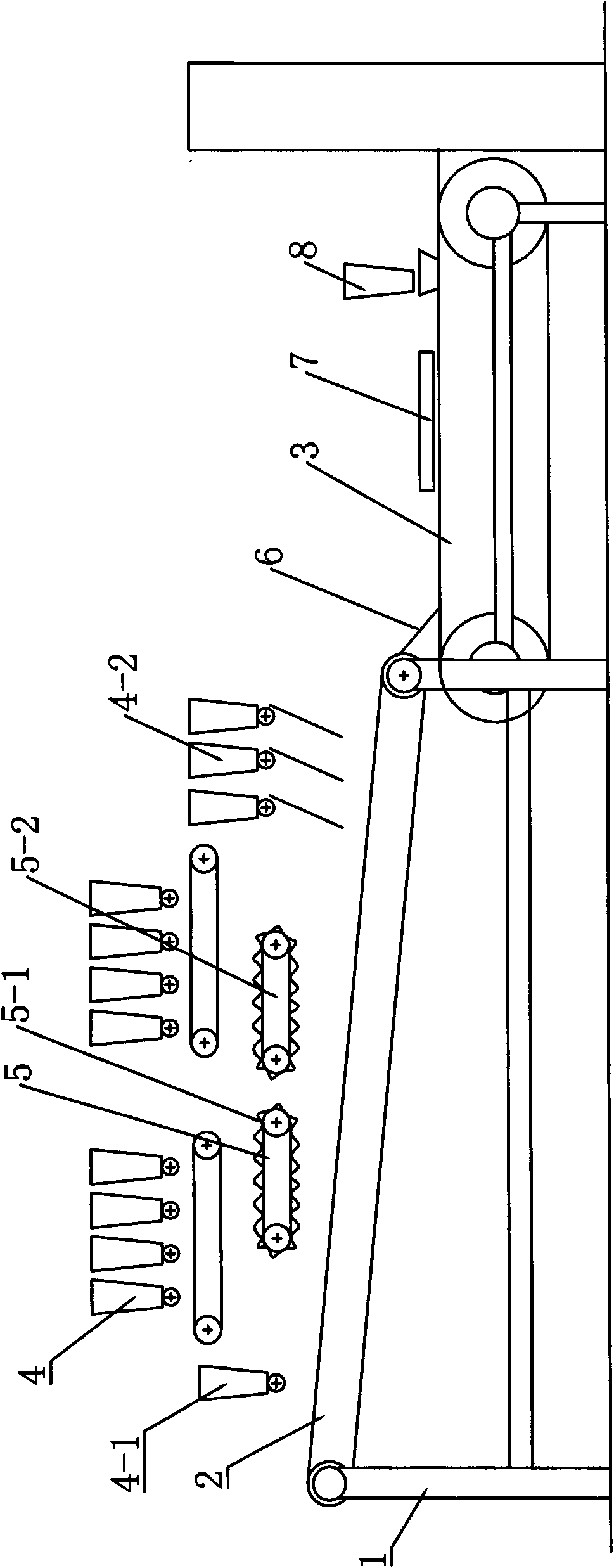

[0028] A porcelain tile micropowder distributing process of the present invention is improved on the basis of the traditional base material twice distributing and reverse micropowder distributing process and line distributing technology, and it comprises the following steps:

[0029] a. Spread the line material on the inclined conveyor belt;

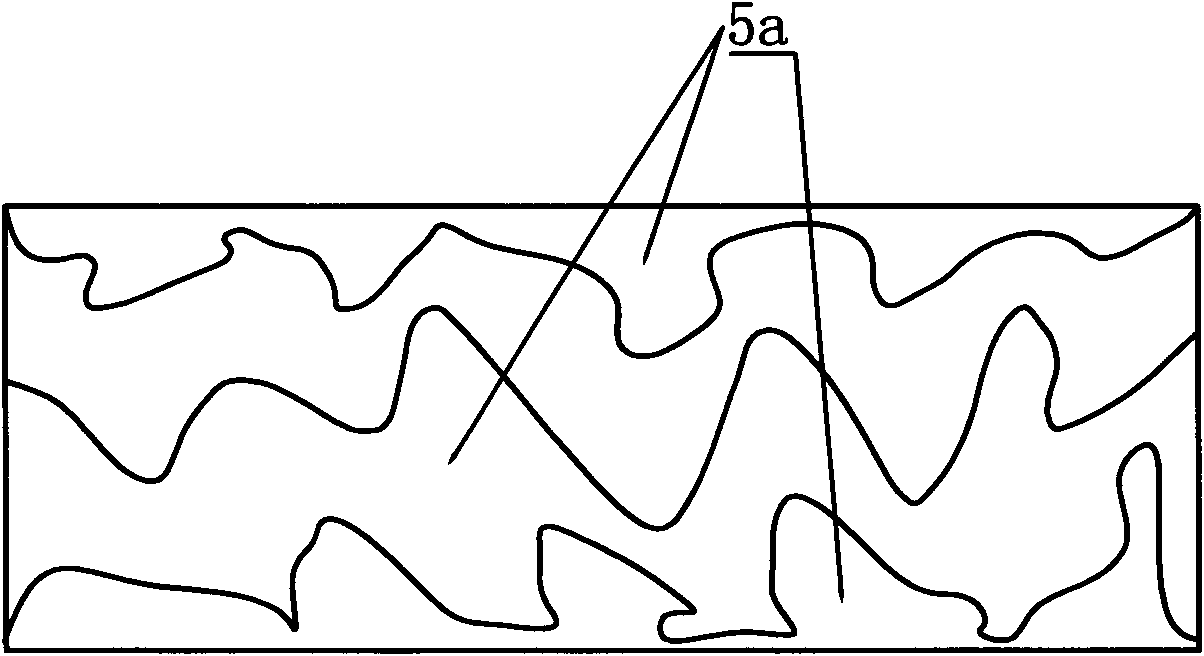

[0030] b. In the way of multi-station intermittent fabric, different types of milky raw materials are intermittently dropped in the flat line material layer to form the wrapping and inlay of milky raw materials and line materials; then different types of transparent raw materials are intermittently dropped on the In the flat line material layer, the wrapping and inlay of transparent material and line material are formed, and the alternating intermittent cloth of opacity material and transparent material is formed on the surface of the board;

[0031] c. Add thread material in the gap position of the cloth station;

[0032] d. Extrude th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com