Mixing and charging machine

A feeder and mixing technology, applied in the field of feeders, can solve the problem of difficulty in controlling the amount of feeding, and achieve the effects of improving efficiency, eliminating control, and avoiding solidification

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

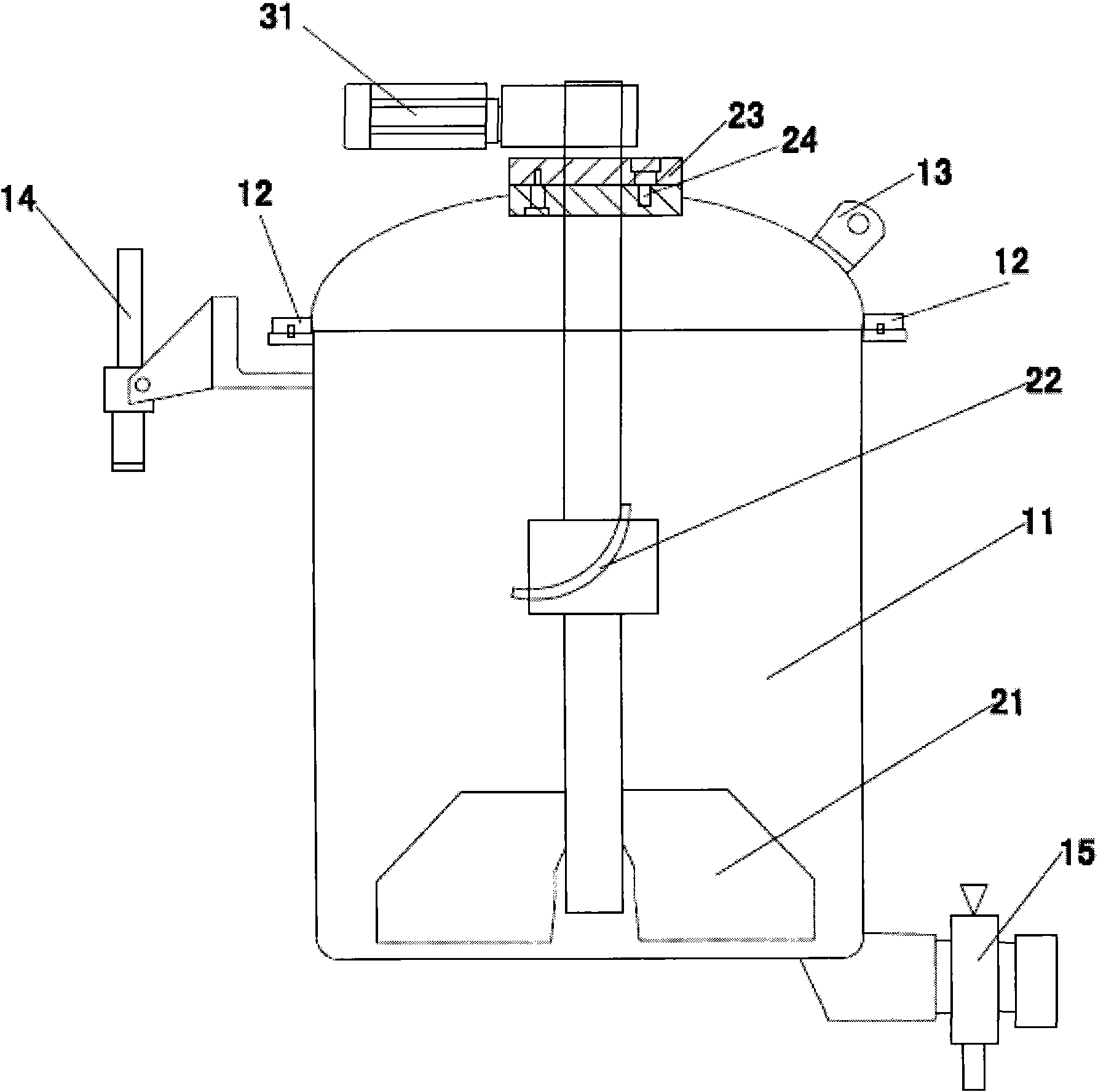

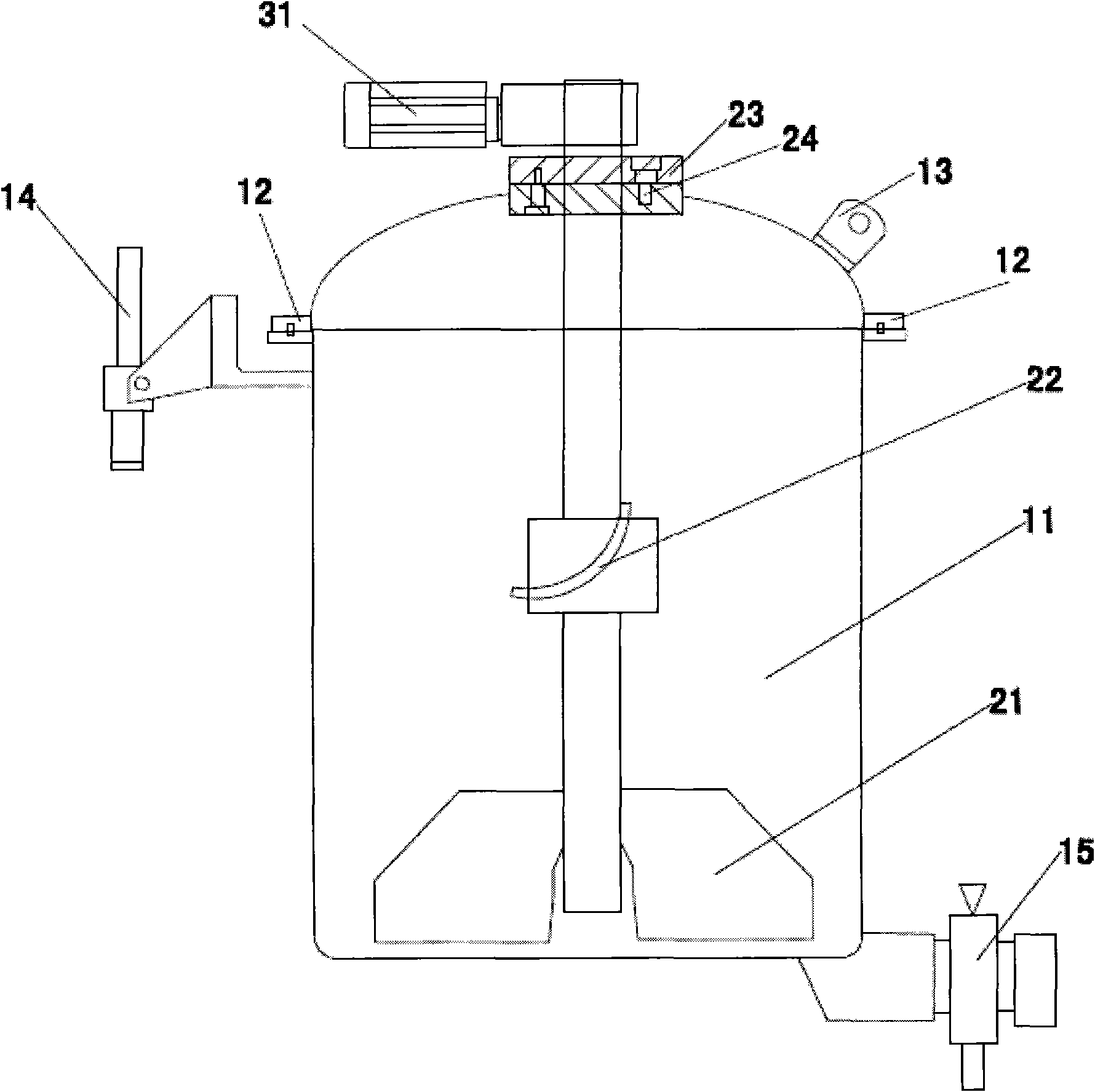

[0016] The invention discloses a mixing and feeding machine, such as figure 1 As shown, it includes a cylindrical body 11 and a hemispherical body cover. The body cover and the two sides of the body 11 are fixed by fixed valves 12. The body cover is provided with a pull-cover button 13 for easy opening of the body cover. The feeder Also comprise a stirring device, said stirring device comprises stirring rod and is arranged on the stirring paddle 21 composition of stirring rod both sides, in order to control the length of stirring rod, so that adjust the height of stirring paddle 21 according to the amount of slurry, on the stirring rod A stirring rod contraction valve 22 for controlling the length of the stirring rod is provided. The stirring device is fixed on a fixing plate 23 provided on the body cover, and is fixedly connected to the body cover by bolts 24 . And extend into the body 11 through the top of the body cover, the top of the stirring device is connected to a mot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com