Device for rotating punching of flat multi-layer goods

A technology of equipment and axis of rotation, applied in the direction of cardboard items, metal processing, etc., can solve problems such as incompatibility between pressure, small adjustment displacement, registration deviation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

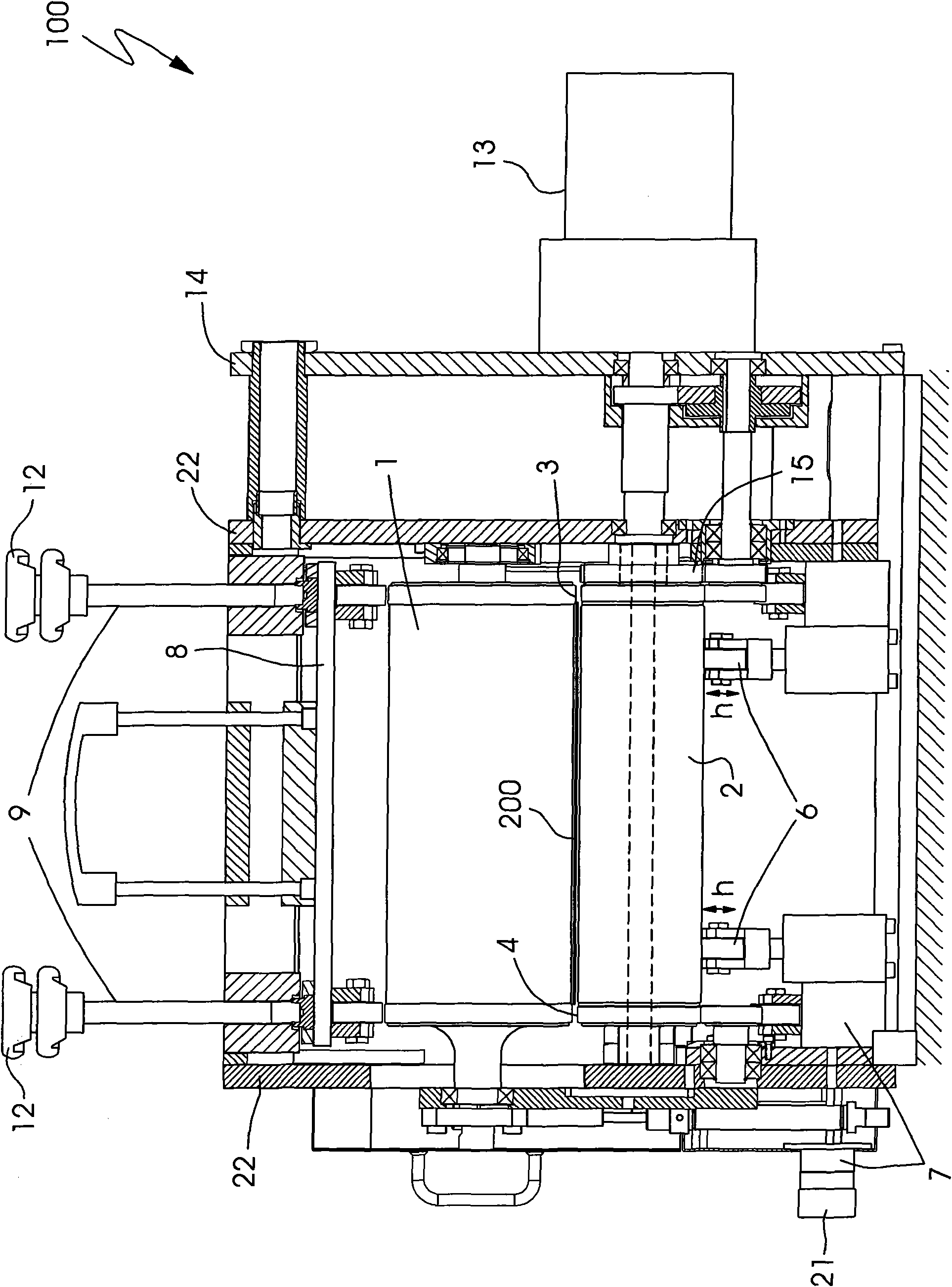

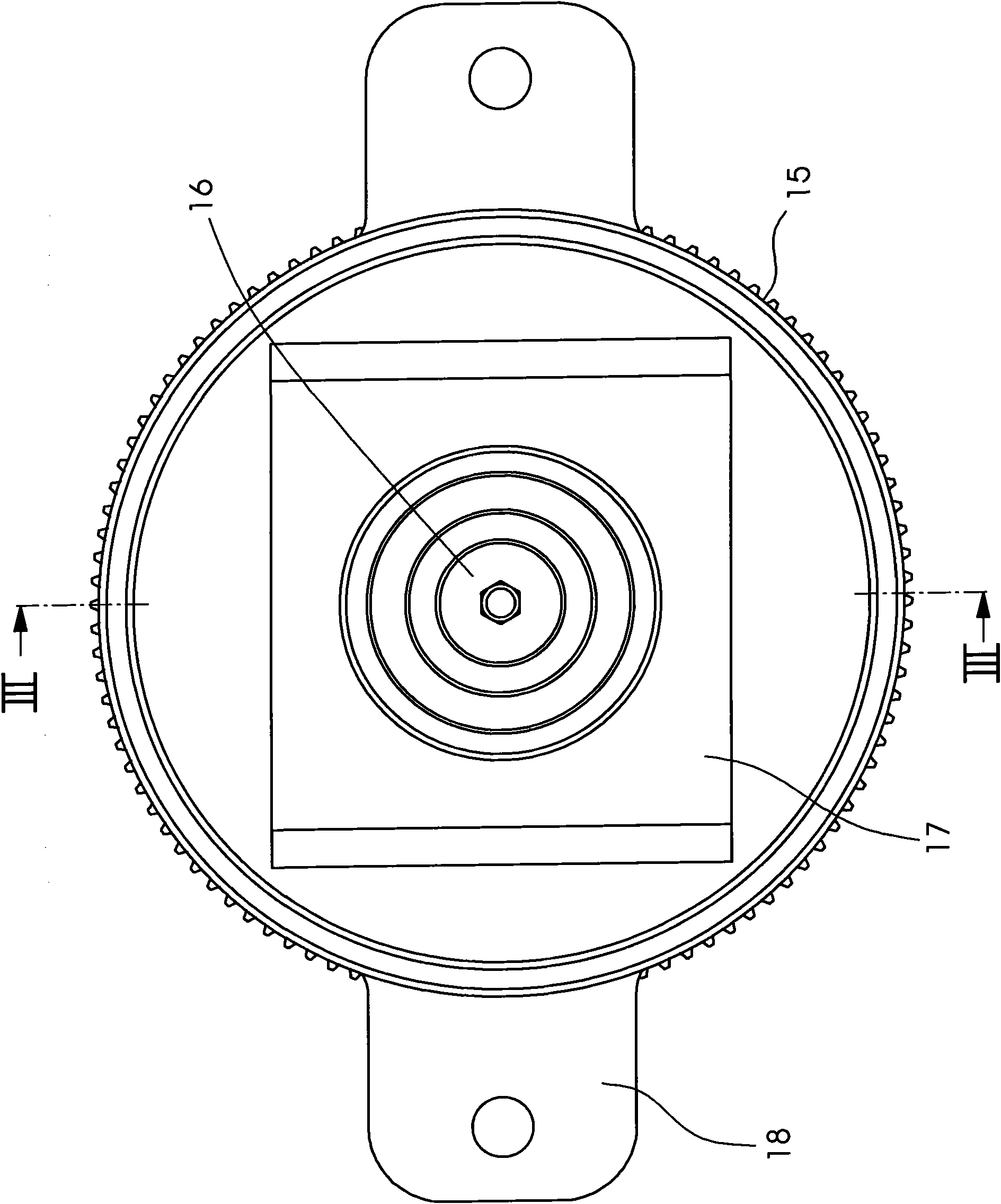

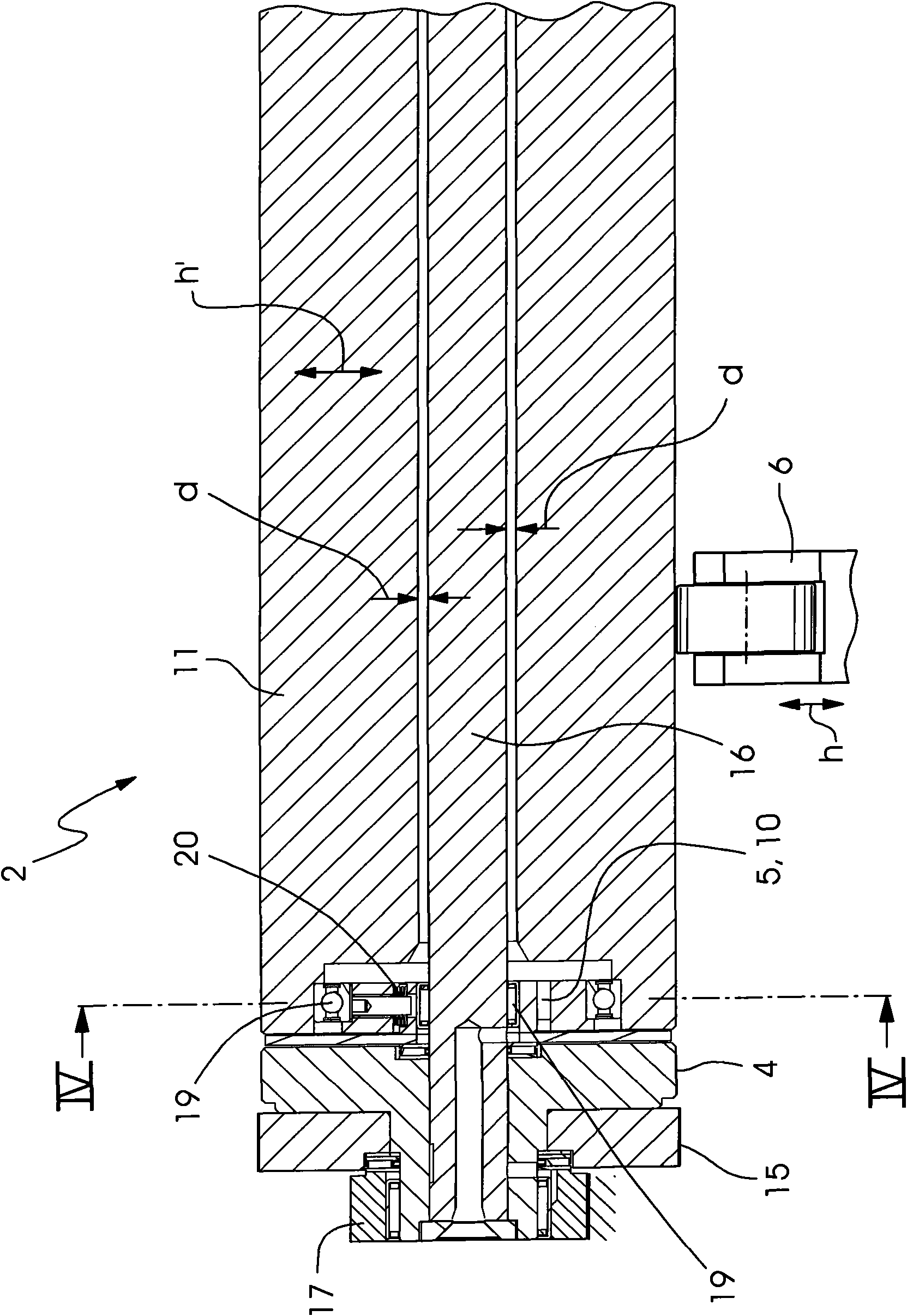

[0029] figure 1A schematic view of an apparatus 100 for punching according to the invention is shown, which is also called a punching apparatus or a rotary punch. The device for stamping has a stamping cylinder 1 and a counterpressing cylinder 2 , between which a printing material 200 is conveyed and subjected to stamping. The stamping cylinder 1 and the counterpressing cylinder 2 are mounted rotatably in a side wall 22 of the stamping device 100 . Roller pillows 3, 4 are assigned to these rollers 1, 2, respectively. The stamping cylinder 1 thus has a rolling pillow 3 at its two outer ends. Roller pillows 4 are arranged on the right and left sides of the mating stamping cylinder 2 . The rollers 3 assigned to the stamping cylinder and the rollers 4 assigned to the mating stamping roller roll on each other. The force take-up of the stamping force from the stamping cylinder 1 takes place via the rollers 4 via the rollers 3 of the stamping cylinder 1 . The position of the sta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com