Base plate of ride-type rice field transplanter

A technology of rice transplanter and bottom plate, which is applied in the direction of transplanting machinery, application, agriculture, etc. It can solve the problems of being unable to adapt to mechanical transplanting, the bottom plate sinking into the soil, and the seedlings crowding, so as to reduce weight, reduce forward resistance, reduce The effect of power consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

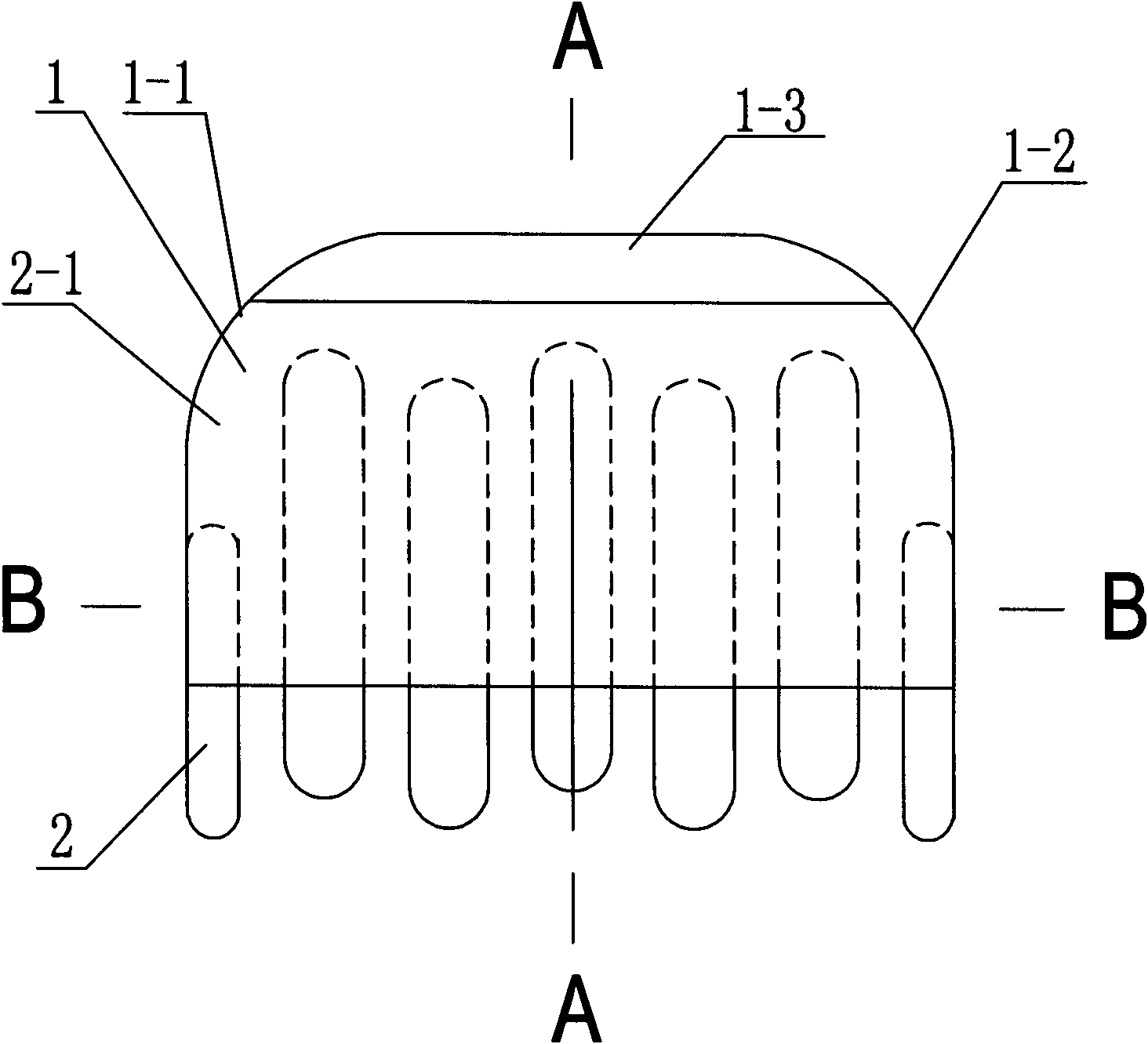

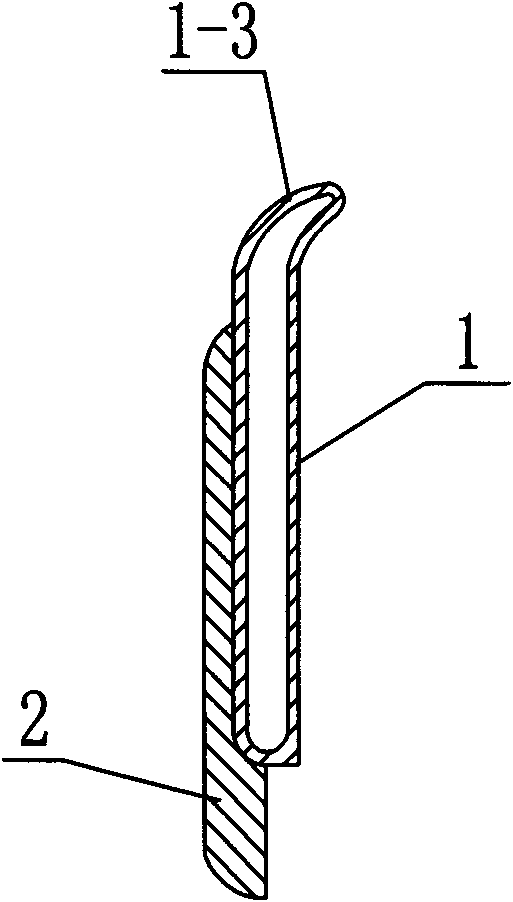

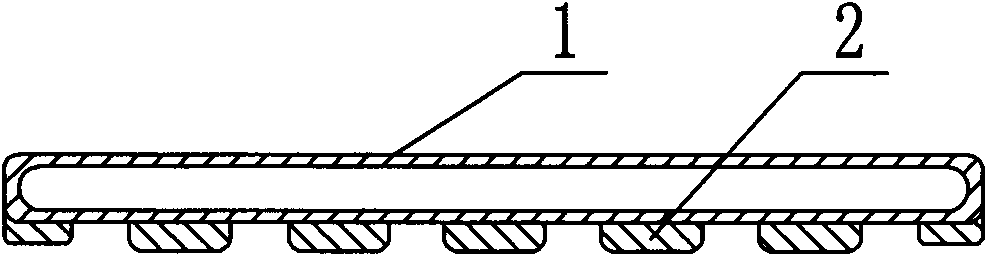

[0013] Such as figure 1 , 2 As shown in . and 3, the plate body 1 of the present invention is a hollow plate body formed by plastic blow molding or injection molding at one time. On the back side of the plate body 1 and along the length direction of the plate body, several convex strips 2 are set by injection molding, and , The front end of each protruding line 2 is respectively provided with an arc surface 2-1.

[0014] The front end of the plate body 1 and both sides are transitionally connected by arc surfaces 1-1 and 1-2 respectively. The front end of the plate body 1 is in an upturned shape, and the back is transitionally connected by an arc surface 1-3.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com