Combined electrode column of vacuum arc extinguishing chamber

A vacuum interrupter, combined technology, used in high-voltage air circuit breakers, electrical components, electric switches, etc., can solve the problems of broken and scrapped epoxy resin and silica gel, weak heat dissipation capacity, and large investment, and achieves It is beneficial to convection and heat conduction heat dissipation, easy installation and replacement, and the effect of improving heat dissipation conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

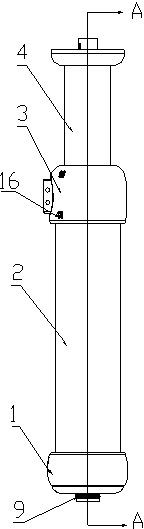

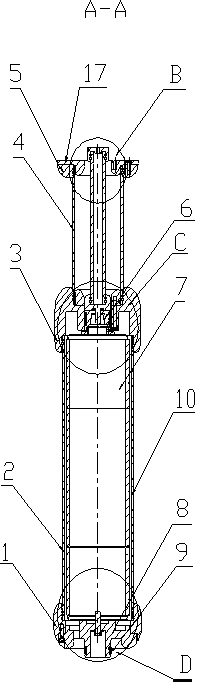

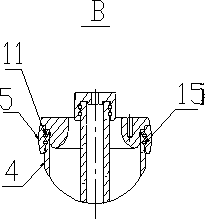

[0031] As shown in the drawings, the present invention includes a shielding electrode 1, a lower insulating cylinder 2, an upper outlet terminal 3, an upper insulating cylinder 4, an upper shielding ring 5 and a mounting flange 17, and the upper shielding ring 5 and the upper insulating cylinder 4 are connected to each other The first epoxy resin pouring point 11 composed of two annular grooves 15 is set at the position, and the second epoxy resin composed of two annular grooves 15 is arranged at the part where the upper insulating cylinder 4 and the upper outlet end 3 are connected to each other. The pouring point 12, the third epoxy resin pouring point 13 composed of two annular grooves 15 is set at the part where the upper outlet end 3 and the lower insulating cylinder 2 are connected to each other, and the third epoxy resin pouring point 13 is set at the part where the lower insulating cylinder 2 and the shielding electrode 1 are connected to each other There is a fourth ep...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com