Transparent-medium-microsphere-based super-resolution microscopic imaging system

A technology for microscopic imaging and transparent media, applied in microscopes, material excitation analysis, optics, etc., can solve the problems of complex system structure, cumbersome sample processing, limited use range, etc., to achieve high resolution fineness, real and reliable images, low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0058] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments, but the present invention is not limited thereto.

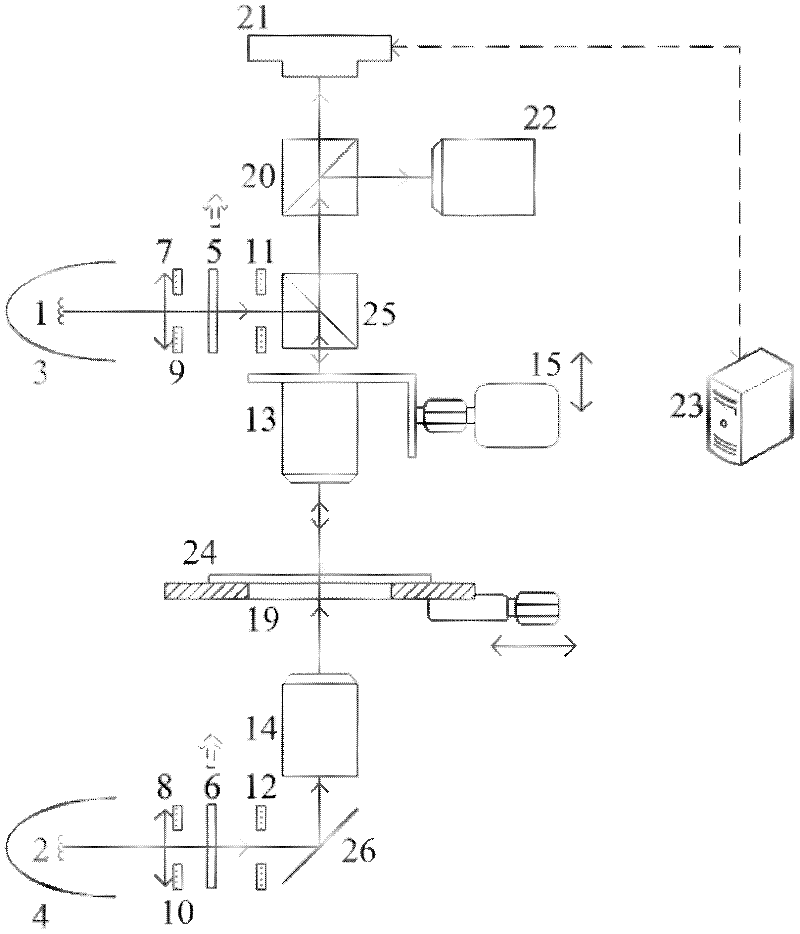

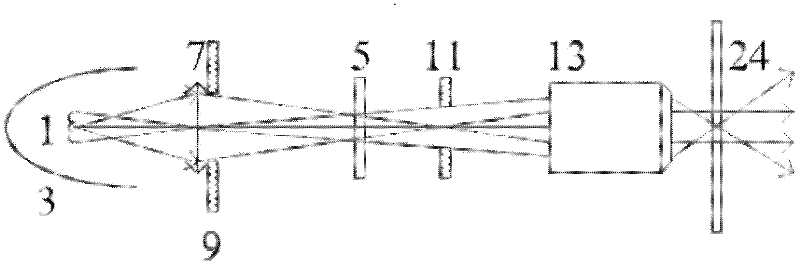

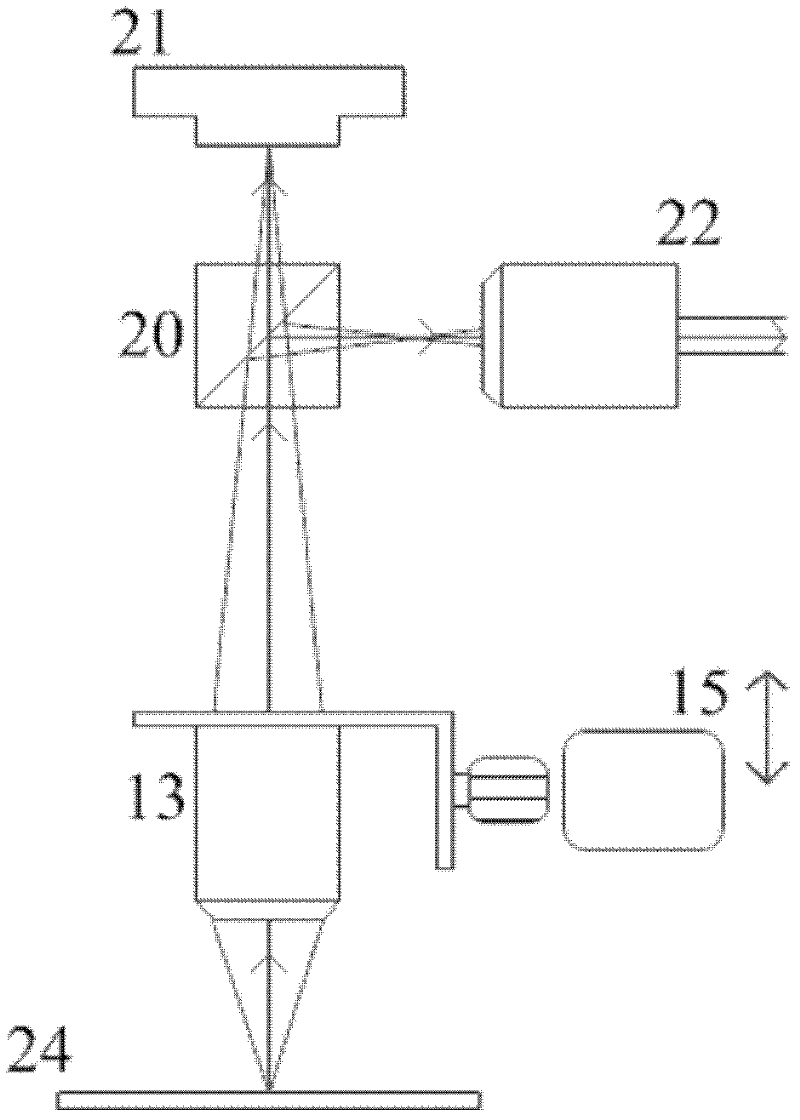

[0059] figure 1 It is a structural schematic diagram of a traditional wide-field optical microscope system, including a first light source 1, a second light source 2, a first parabolic reflective bowl 3, a second parabolic reflective bowl 4, a first wide-spectrum linear polarizer 5, and a second parabolic reflective bowl. Two broad-spectrum linear polarizers 6, the first Kohler lens 7, the second Koehler lens 8, the first field stop 9, the second field stop 10, the first aperture stop 11, and the second aperture stop 12. The first microscopic objective lens 13, the second microscopic objective lens 14, the coarse adjustment device 15, the sample holder 19, the beam splitter prism 20, the charge coupled device (Charged Coupled Device, CCD) 21, the microscopic eyepiece 22, the computer 23, the beam split...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com