Damping regulating mechanism of shock absorber

A damping adjustment and shock absorber technology, applied in shock absorbers, shock absorbers, springs/shock absorbers, etc., can solve problems such as low reliability, large delay in damping adjustment, and shock absorbers losing their damping adjustment function. , to achieve good reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

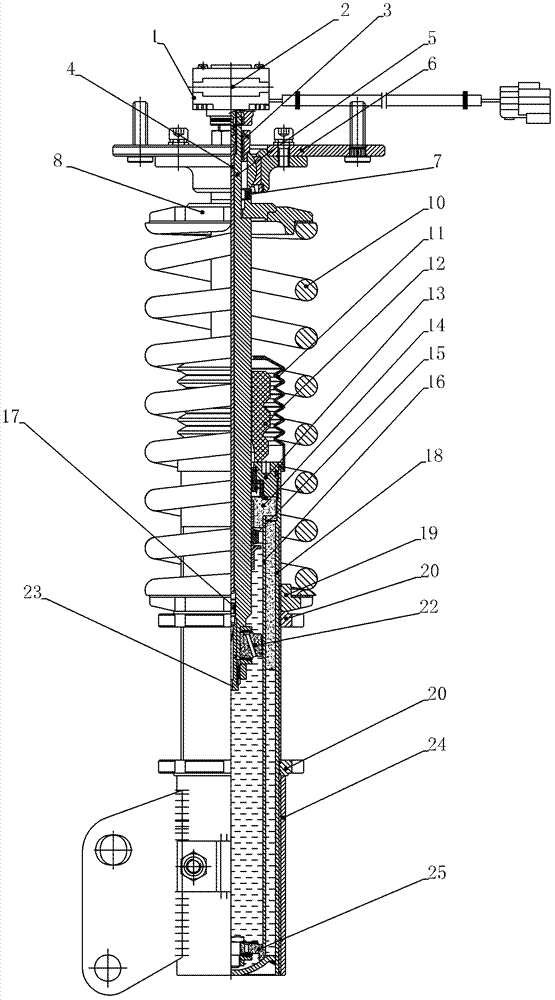

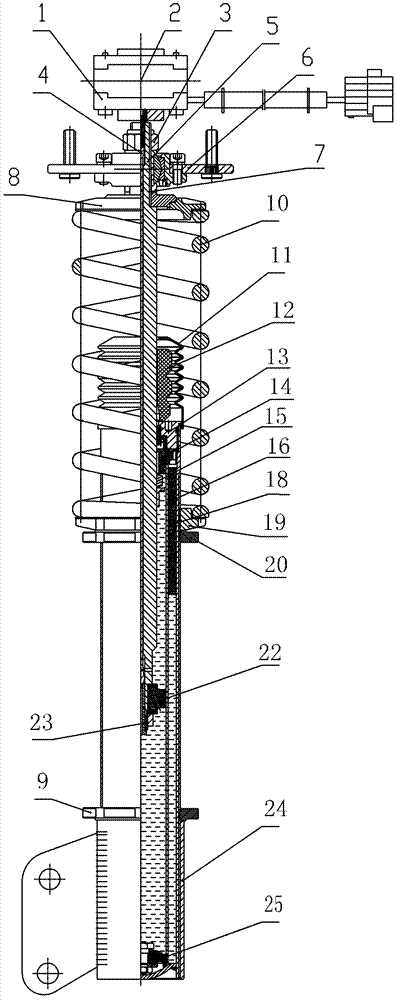

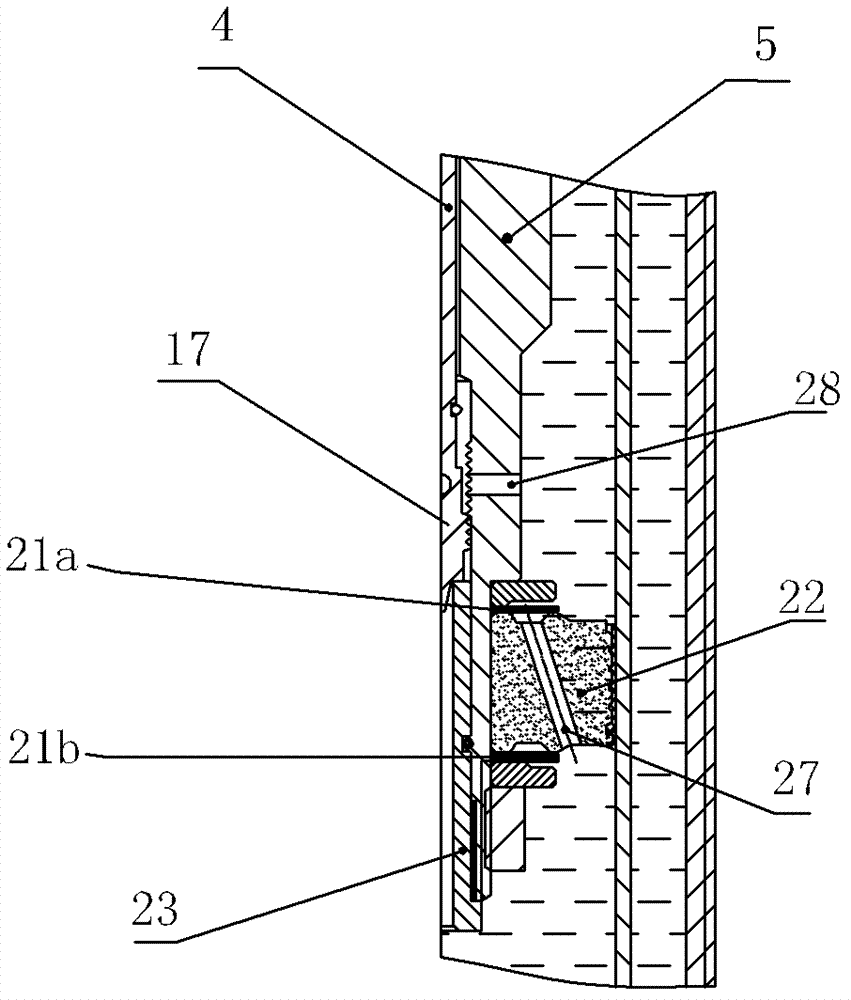

[0013] See Figure 2-3 , the damping adjustment mechanism of the shock absorber of this embodiment includes: an electric adjustment system 1, a sliding device and a lower adjustment system, and the sliding device includes: an inner shaft 4 arranged in an axial through hole in the piston rod 5 of the shock absorber , and a sliding thimble 17 that is located at the bottom of the inner shaft 4 and integrated with the inner shaft 4; the inner shaft 4 is in transmission connection with the electric adjustment system 1; the lower adjustment system includes a piston 22 located at the bottom of the piston rod 5, and the piston 22 A first flow hole 27 is provided. The sliding thimble 17 is threadedly matched with the axial through hole at the bottom of the piston rod 5;

[0014] In order to further facilitate the electric damping adjustment, the electric adjustment system 1 includes: an upper hanging positioning plate 6 arranged on the upper end of the piston rod 5 through a nut 3, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com