In-time sediment adding system for tidal estuary sediment physical model

A physical model and sediment technology, applied in the hydraulic model, etc., to improve work efficiency, eliminate the influence of human factors, and ensure the accuracy of sand filling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention takes the Qiantang River estuary model Gaza system as an example to illustrate specific implementation schemes.

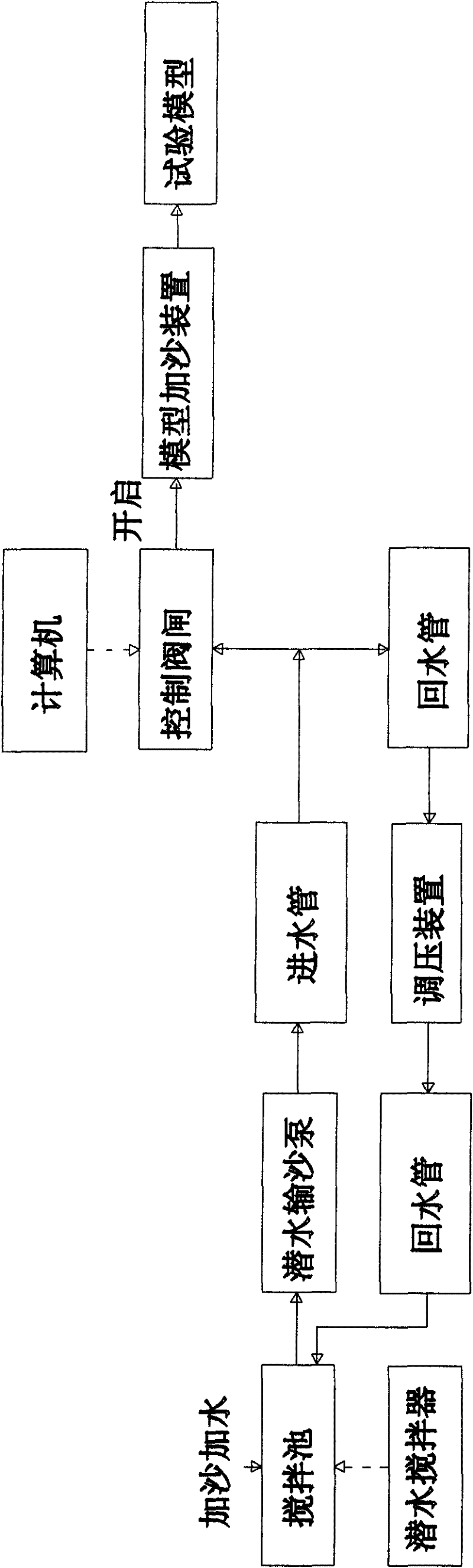

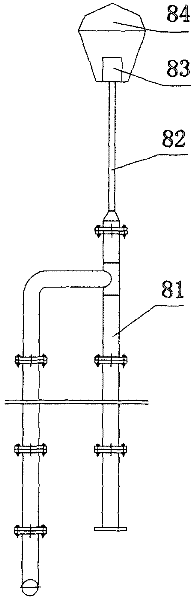

[0020] Such as figure 2 As shown, the system consists of a sand mixing tank 1, a submersible mixer 2, a submersible sand delivery pump 3, a sand delivery pipeline inlet pipe 4, a sand delivery pipeline return pipe 5, a control gate valve 6, a model sand adding device 7, a pressure regulating device 8, Computer and its control software 9 and so on.

[0021] The mixing tank 1 is made of concrete, which is used to prepare and accommodate sandy and muddy water. The size of the capacity depends on the amount of sand added to the tidal estuary sediment model. In this embodiment, the mixing tank is 2 meters deep, 3 meters in diameter, and has a water capacity of about 14 cubic meters, the mixing tank is 1 meter above the ground, buried 1 meter in the ground, and the structure is reinforced concrete.

[0022] The submersible mixer 2 is insta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com