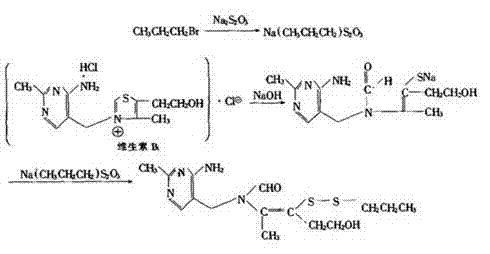

Preparation method of sodium n-propyl thiosulfate

A technology of propyl sodium thiosulfate and sodium thiosulfate, which is applied in the field of medicine and chemical industry, can solve the problems of long preparation time, long reaction time, and high consumption of polyethylene glycol, so as to reduce reaction time, reduce consumption, and save cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] 1. Add 74.5g of sodium thiosulfate pentahydrate to the high-speed shear reactor, dissolve it with an equal amount of distilled water, then add polyethylene glycol 400, 1.5g, n-bromopropane 44g, and adjust the speed to 7000r / min~8000r / min , heated to reflux, and reacted for 2 hours.

[0020] 2. After the reaction was completed, the content of n-propyl sodium thiosulfate was analyzed to be 27%, and the yield was 98% (calculated as sodium thiosulfate).

Embodiment 2

[0022] 1. Add 74.5g of sodium thiosulfate pentahydrate into the high-speed shear reactor, dissolve it with an equal amount of distilled water, then add 400, 2g of polyethylene glycol, 44g of n-bromopropane, and adjust the speed to 6000r / min~7000r / min. Heat to reflux and react for 2 hours.

[0023] 2. After the reaction was completed, the content of n-propyl sodium thiosulfate was analyzed to be 26%, and the yield was 95% (calculated as sodium thiosulfate).

Embodiment 3

[0025] 1. Add 74.5g of sodium thiosulfate pentahydrate into the high-speed shear reactor, dissolve it with an equal amount of distilled water, then add polyethylene glycol 400, 1g, n-bromopropane 44g, adjust the speed to 8000r / min~10000r / min, Heat to reflux and react for 2 hours.

[0026] 2. After the reaction was completed, the content of n-propyl sodium thiosulfate was analyzed to be 26.5%, and the yield was 96.5% (calculated as sodium thiosulfate).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com