Slideway type metal circular sawing machine

A circular saw machine and slideway-type technology, which is applied in the direction of metal sawing equipment, metal processing equipment, sawing machine devices, etc., can solve the problem of burrs, round edges, flashes, horseshoes on the cutting surface, which affect the smoothness of the cutting surface and Sawing accuracy, large cutting force and other issues, to achieve the effect of small vibration, strong rigidity and safe use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

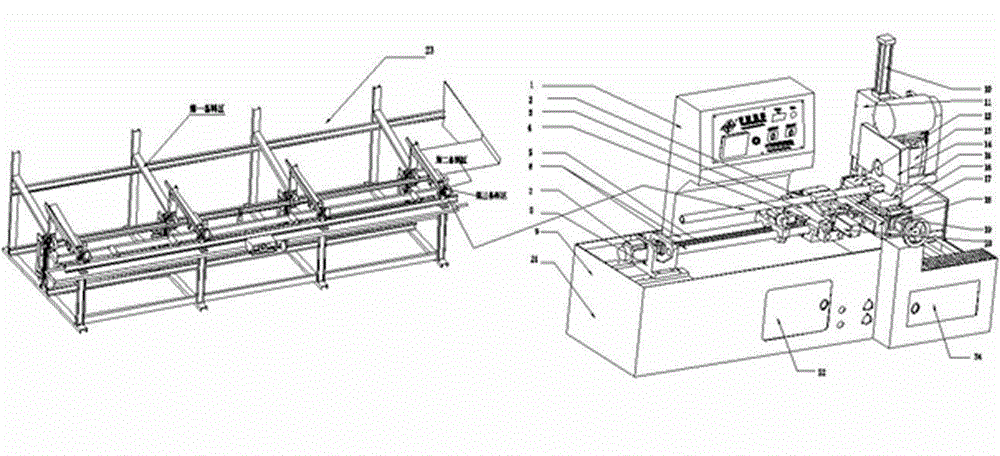

[0017] The present invention will be further described below in conjunction with accompanying drawing and embodiment, as figure 1 As shown, the present invention CNC-400 The slide type metal circular saw machine includes a body 9, a feeding device installed on the body 9, a knife feeding device, a one-piece seat 8, a servo motor 7 and an electric control box 1, and also includes an automatic Automatic material preparation device 23 for feeding and feeding. CNC-400 The slide type metal circular saw machine adopts multi-set gear linkage chassis, super powerful design, the motor synchronously drives multiple sets of gears to drive the main shaft, the high and low speeds can be adjusted, the operation is stable and noiseless, the saw blade safety cover 14 is fixed on the machine head 13 and the front and rear clamping saw blade devices are installed to make the saw blade not easy to swing, which better guarantees its sawing accuracy; the base 17 is fixed on the right end of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com