Ultrahigh casting modeling method

A production method and casting technology, which are applied in the directions of casting molds, casting mold components, casting molding equipment, etc., can solve the problems of increasing efficiency and unable to continue processing operations.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

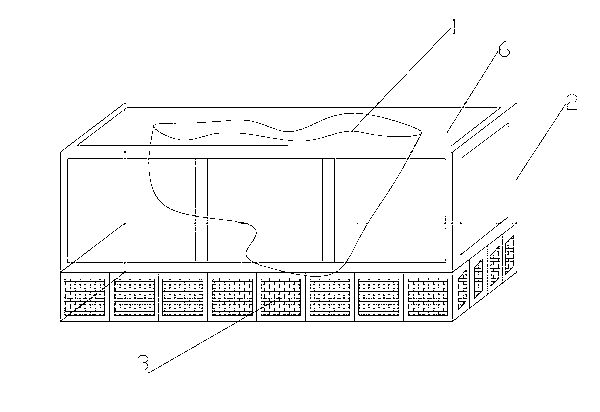

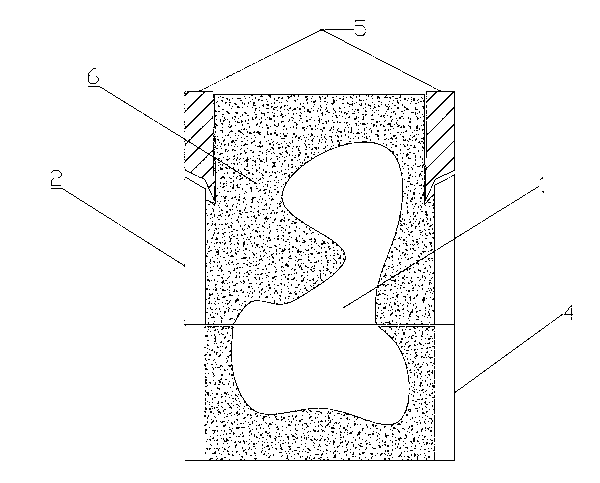

[0010] In order to gain an in-depth understanding of a model making method for super high castings, combined with Figure 1 to Figure 3 described as follows:

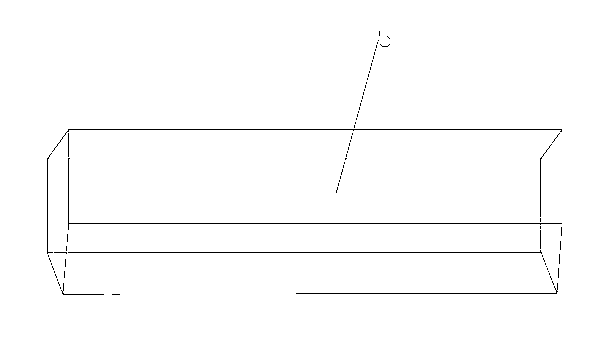

A method for making a model of an ultra-high casting, comprising the use of a lower sand box 4, an upper sand box 2 and pressure bricks 3, and stacking the pressure bricks 3 on the ground on a horizontal workbench with the frame of the upper sand box 2 as a boundary On the top, the height is 10-20cm, enclosing a cavity with a height of 10-20cm, place the upper sand box 2 on the pressure brick 3, align and fix the surroundings, add the bottom sand, put it into the mold 1, wash the sand 6, After the sand 6 is finalized, the upper sand box 2 is lifted, turned over and combined with the lower sand box 4, and the exposed 10-20cm edge of the upper sand box 2 is inserted with a steel plate liner 5 around it, and after being inserted into the edge of the upper sand box 2, Its height is the same as the exposed edge height. Th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com