A kind of collective socket, panel and plug of medical instrument

A technology for socket panels and medical instruments, used in coupling devices, fixed connections, fixed/insulated contact members, etc., can solve the problems of uneven appearance, difficult miniaturization, and difficult design integration, saving mold development and after-sales maintenance. Cost, prevent mis-insertion, misuse or damage to the instrument, and the effect of convenient production, maintenance and replacement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

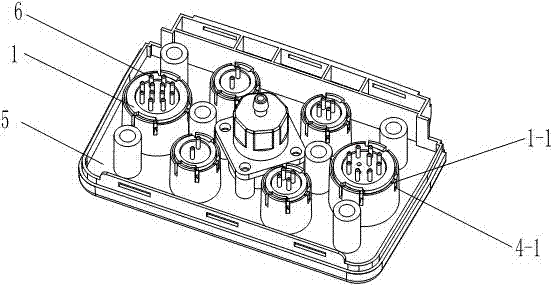

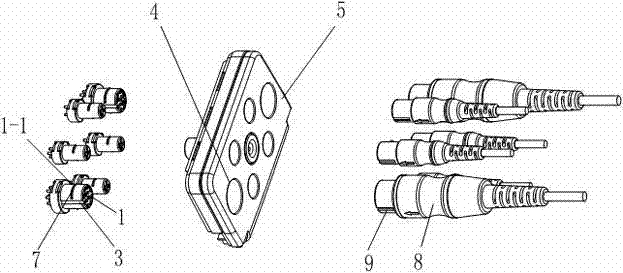

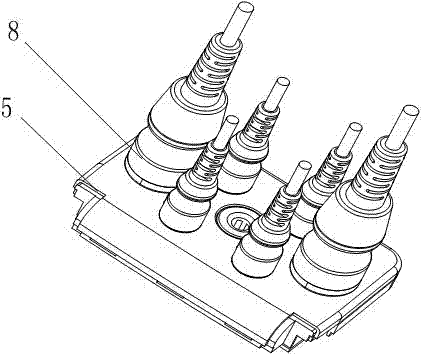

[0024] see Figure 1-Figure 5 , is an embodiment of a medical instrument assembly socket, panel and plug of the present invention, including a socket panel 5, a socket 1 in the socket hole 4 of the socket panel and a plug 8 matching the socket, and each socket 1 is embedded in the same Corresponding socket panel socket holes 4 on the socket panel 5 are positioned through the card-type positioning grooves.

[0025] The socket hole 4 of the socket panel extends out of a cylinder vertically on the back of the socket panel, and there are at least two vertical grooves 4-1 along the edge of the cylindrical lower port of the socket hole 4 of the socket panel, that is, the snap-type positioning Groove 4-1, a vertical protruding bar 1-1 corresponding to the card-type positioning groove 4-1 is provided on the annular outer wall of the lower part of each socket 1. When assembling, insert the socket 1 from the back of the socket panel 5 into the socket panel socket hole 4, and rotate the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com