Self-tightening rope

A rope and hollow technology, applied in the direction of transmission elements or pulley ropes or cables, textile cables, belts/chains/gears, etc., can solve problems such as complex structures, inability to realize rope self-tightening fixation and simple release

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

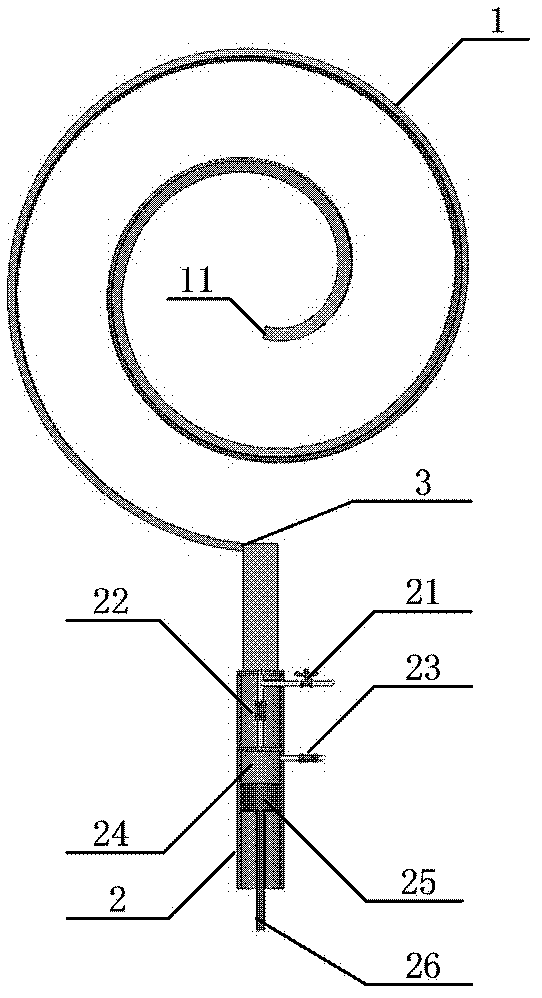

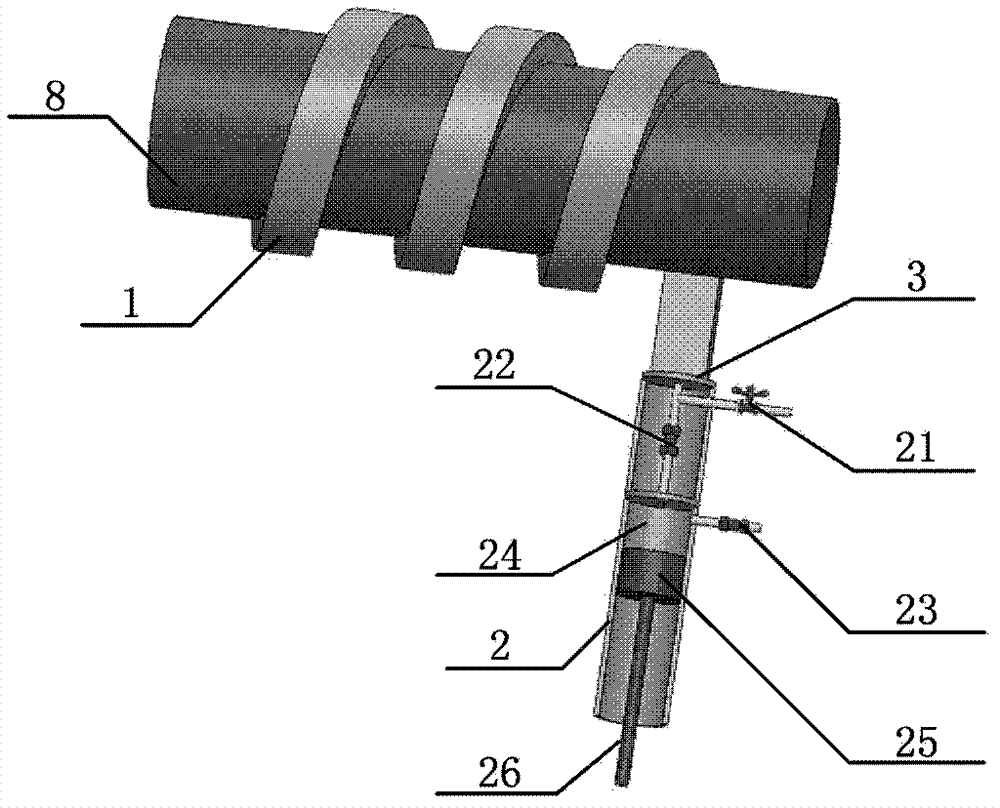

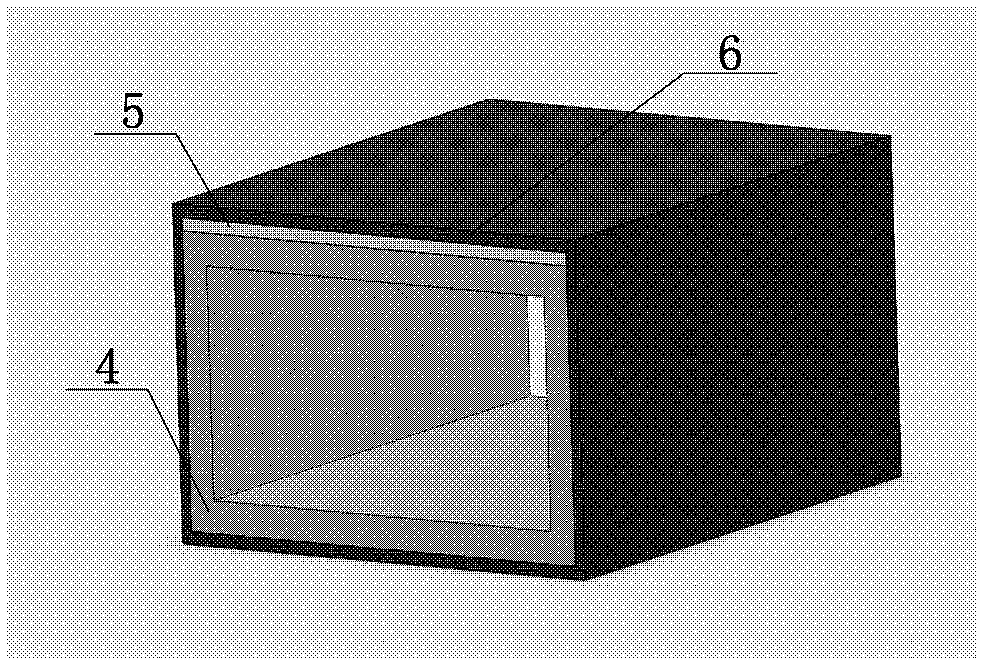

[0022] Strapping - see Figure 5 described as follows:

[0023] First close the pressure relief valve 21, then wind the Bourdon tubular hollow rope 1 around the bundle 8, so far, the preparatory work is completed, and the bundle can be started. The pumping rod 26 moves to start pumping air. At this time, the one-way valve I22 is opened, and the one-way valve II23 is closed. The gas in the Bourdon tubular hollow rope 1 enters the cylinder 24 through the one-way valve I22. When the pumping rod 26 moves to When at the limit position, the pumping ends, and the one-way valve I22 is closed. When the pumping rod 26 reversely moves, the one-way valve II23 is opened, the one-way valve I22 is closed, the gas in the cylinder 24 is discharged through the one-way valve II23, and enters the atmosphere, and the exhaust process ends. The pumping rod 26 reciprocates to perform the pumping and exhausting process repeatedly. Since one end of the Bourdon tubular hollow rope 1 is closed, the int...

Embodiment 2

[0025] Suspension - Suspension is used in much the same way as strapping

[0026]Firstly close the pressure relief valve 21, then wrap the Bourdon tubular hollow rope 1 on the binding object, so far, the preparatory work is completed, and the fastening and fixing can be started. The pumping rod 26 moves to start pumping air. At this time, the one-way valve I22 is opened, the one-way valve II23 is closed, and the gas in the Bourdon tubular hollow rope 1 enters the cylinder through the one-way valve I22. When the pumping rod moves to the limit position , the pumping ends, and the one-way valve I22 is closed. When the pumping rod moves in reverse, the one-way valve II23 is opened, and the one-way valve I22 is closed, and the gas in the cylinder passes through the one-way valve II23, is discharged from the cylinder by the pumping rod 26, and enters the atmosphere, and the exhaust process ends. The pumping rod 26 reciprocates to perform the pumping and exhausting process repeatedl...

Embodiment 3

[0029] According to the use requirements of the rope, the air suction device 2 can be replaced by an automatic suction pump, and the air pressure in the rope can be changed by electric or other power methods, causing the "tightening" and "releasing" actions of the Bourdon tubular hollow rope . According to the use environment of its rope, the pressure regulating medium in the rope body can be gas or liquid.

[0030] The main working principle remains roughly the same. First, the pressure relief valve 21 is closed, and then the Bourdon tubular hollow rope 1 is wound on the tying object. At this point, the preparatory work is completed, and the tying can be started. The pumping device starts pumping, and now the one-way valve I22 is opened, and the gas in the Bourdon tubular hollow rope is extracted through the one-way valve I22, and when the pumping ends, the one-way valve I22 is closed. Since one end of the Bourdon tubular hollow rope is closed 11 , the interior of the Bourdo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com